Ramsey Winch RPH-8000Y (JERR-DAN) User Manual

Page 8

ADJUSTING THE BRAKE

All parts of the oil-cooled automatic safety brake are bathed in oil. When the brake wears

to the point that the load begins to drift, the brake can be adjusted as follows:

1. Loosen the lock nut on the adjusting screw (see drawing on page 9).

2. Increase the brake torque by turning the adjusting screw clockwise. CAUTION: Only

1/4 turn is usually required to adjust the brake. Over-tightening can cause overheat-

ing, and damage to the brake parts. Tighten the lock nut after adjustment is

completed.

If the brake does not respond to adjustment, then a new flat spring (item #4) and/or brake

discs (item #33) may be needed.

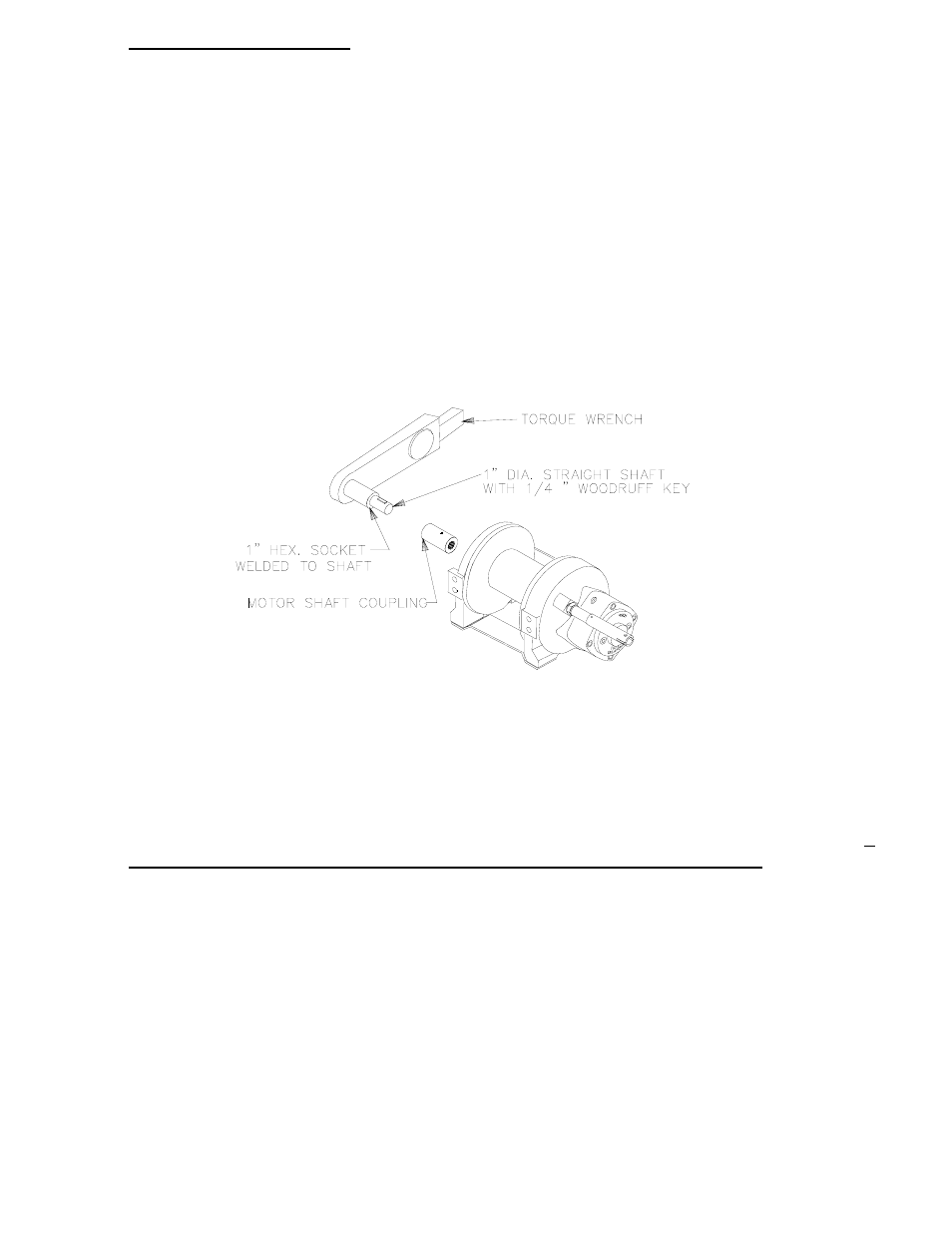

Brake torque can be checked/set as follows: A torque wrench can be equipped with a

special adapter to fit the input coupling of the winch. The adapter can be made by welding

a 1" dia. straight motor shaft, with 1/4" key, in a 1" hex. socket, as shown in the following

figure.

This special adapter will fit into the motor shaft coupling. Place coupling onto drum

shaft in winch. Turn the torque wrench so that the drum turns in the "CABLE OUT"

direction (lowering direction). The torque setting for the brake should be 155 to 160 ft.

lbs. If the torque wrench does not show the proper torque value, the adjusting screw

should be adjusted 1/4 turn (clockwise if torque is low or counter-clockwise if torque is

high). Each time the adjusting bolt is turned, check the torque reading. Continue this

procedure until the proper torque reading is achieved. Then tighten the lock nut. If

proper adjustment cannot be made, follow overhaul instructions on page 9.

After the brake has been adjusted to the proper torque setting, as described above,

disengage clutch. Start vehicle engine and run winch in the "CABLE IN" (raise

direction). Allow winch to run in this direction for one minute.

Place your hand on the brake housing. If housing is not hot to the touch then run winch

in the reverse direction (cable out) for one minute. Brake housing should begin to heat.

When these conditions exist, proper installation has been made. If heating becomes

noticeable when running the winch in "CABLE IN" (raising direction), the brake should be

again disassembled. When disassembled, place the brake balls in the alternate set of

slots in the cam plate (see View A-A page 9), then carefully follow the instructions for

re-assembling and checking the brake.

6