Ramsey Winch RPH 53,3 User Manual

Page 10

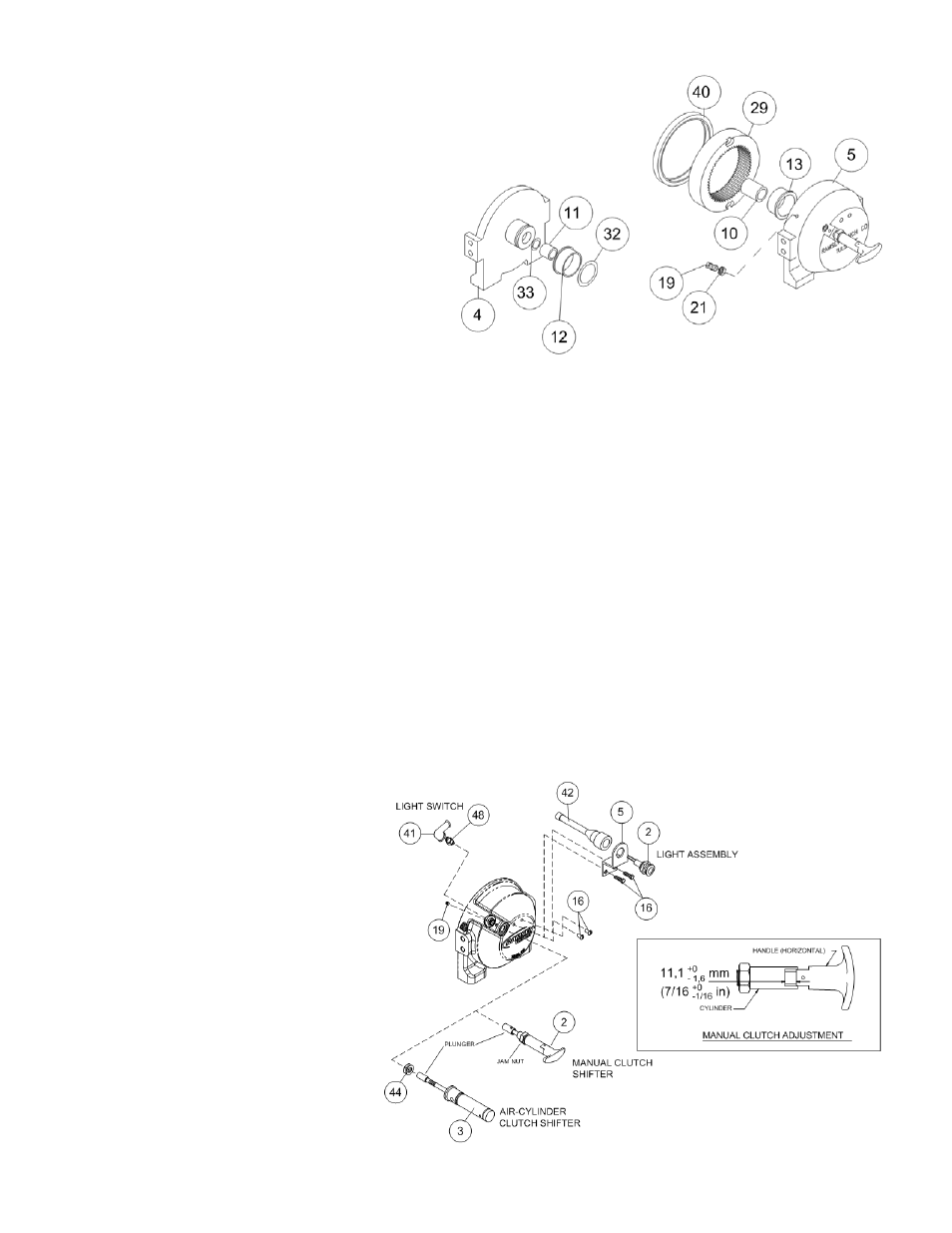

Remove o-ring (item #32), bushing (item #12) from outside of

motor end bearing (item #4), remove o-ring (item #33), bearing

(item #11) from inside of motor end bearing (item #4). Place

new, well oiled, o-ring (item #33) into groove inside of end

bearing and press new bearing (item #11) into end bearing.

Press bushing (item #12) onto end bearing and dip o-ring

(item #32) in oil and seat into groove of end bearing.

Remove seal (item #40) from gear housing end bearing (item

#5). Loosen nut (item #21) and remove nylon setscrew (item

#18) and remove ring gear (item #29) from gear housing end

bearing, if necessary. Remove bushing (item #13) and bearing

(item #10) from gear housing end bearing (item #5). Press new

bushing (item #13) and bearing (item #10) into place in end

bearing. Install ring gear and nylon setscrew and nut. Ring gear

must be fully seated in gear housing end bearing (item #5) and

slot in ring gear must NOT be aligned with clutch shifter hole.

Install new seal in gear housing end bearing, with sharp edge of

seal outward.

Generously apply grease (MOBILITH SHC 007) to teeth of ring gear (item #29), teeth of planet gears in drum (item #1) and to bushing in

gear housing end bearing (item #5). Apply a small amount of grease to base of bushing on motor end bearing (item #4). Apply grease to

teeth of gear and short end of shaft (item #8). Place gear end of shaft through thrust washer (item #47) and into bearing in end bearing

(item #5). Place drum over shaft and rotate drum to engage planet gears with output gear on shaft and with ring gear in end bearing.

Assemble end bearing (item #4) to drum assembly and use tie plates (item #9) and capscrews (item #16) to hold both end bearings

together. Tighten capscrews to 75 Nm (55 ft-lb). Slide thrust washer (item #48) over end of shaft and against end bearing (item #4). Place

snap ring (item #41) into groove in splined end of shaft.

If necessary, remove and replace appropriate shifter assembly (item #2 or #3), as follows:

MANUAL CLUTCH SHIFTER ASSEMBLY

Loosen setscrew (item #19) and jam nut, then unscrew manual shifter assembly (item #2). Be sure slot in ring gear is not aligned with

clutch shifter hole. Rotate drum, if necessary, to ensure hole and slot are not aligned.

Reinstall shifter assembly with plunger, jam nut, and handle positioned in gear housing as shown below. Thread assembly (with handle

engaged in cylinder slot) into the gear housing. Pull drum toward the gear end bearing housing to remove play. Hold drum in position and

continue threading the shifter assembly in until the gap between the end of the handle and cylinder is

11,1 +0 - 1,6 mm(7/16

+0

-1/16 in) and handle is in the horizontal position (see below). Note: This gap will vary with drum endplay. With

the drum pulled against the motor end housing, the gap should be 10 mm (.38 in).

Lightly tighten jam nut. Rotate drum until handle snaps fully into the engaged position. Pull handle out and rotate 90°. Verify that drum can be

rotated freely (at least one full revolution) with

clutch shifter at the DISENGAGED position.

Securely tighten jam nut while holding the handle.

Tighten setscrew (item #19) securely. Re-check

clutch operation as described on page 5.

AIR CYLINDER SHIFTER ASSEMBLY

Loosen set screw (item #19) to remove shifter

assembly (item #3). To reinstall, place 1 or 2

shims (items #44) over plunger and thread shifter

assembly into gear end housing. Add or remove

shims to orient ports for pneumatic connections.

Ports should point

down

(below horizontal).

Tighten setscrew. Check for clutch operation as

described on page 5.

If the light assembly (item #2) or light switch

(item #48) needs to be replaced, refer to the

schematic on page 12 for electri

cal connections

and disassemble and reassemble as shown.

10