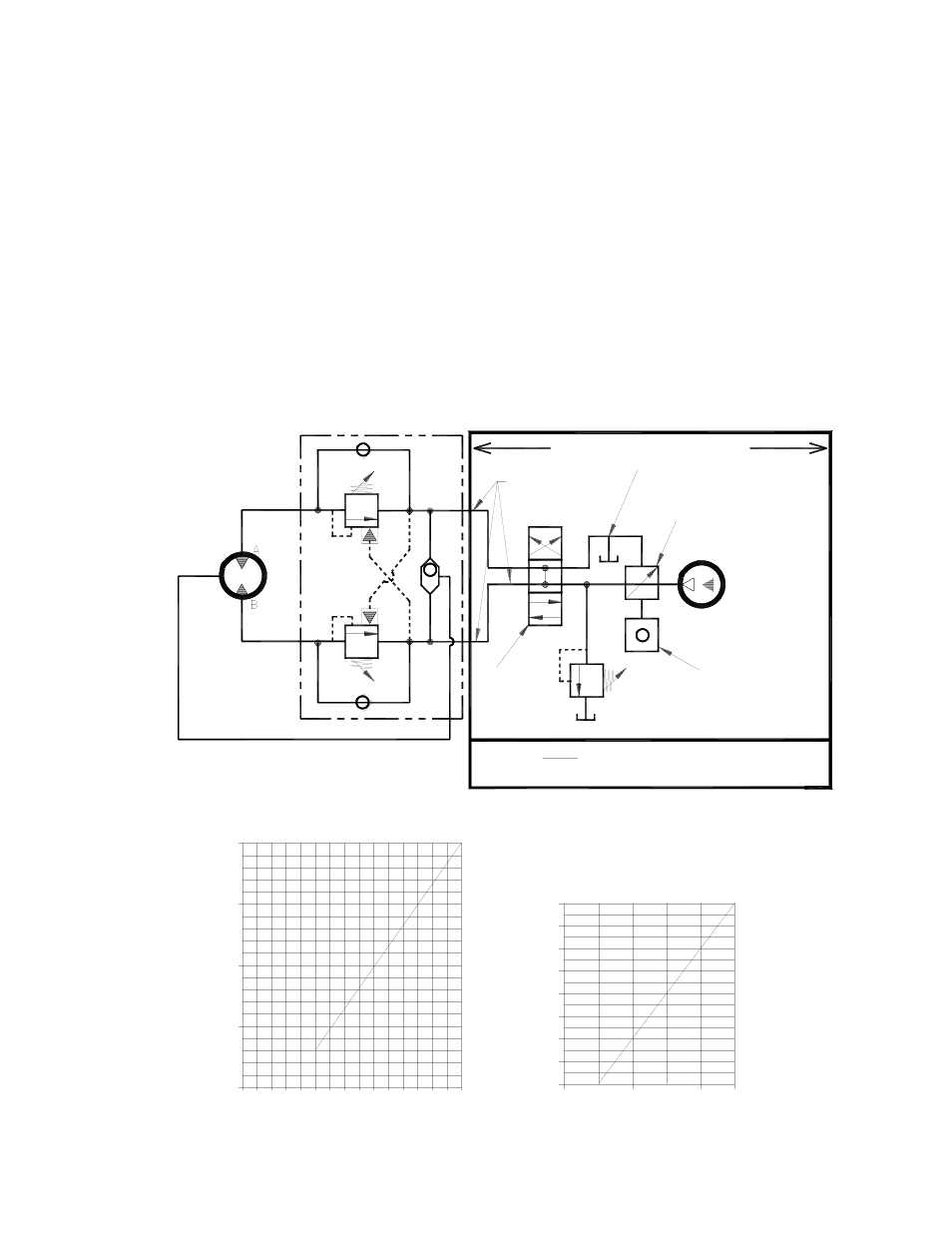

Typical layout, Provided by user, Hydraulic system requirements 1 – Ramsey Winch HD-P 34,9 User Manual

Page 7: Motor spool (open center) control valve, Performance charts

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The charts consist

of: (1) Line Pull first layer kN (lb) vs. Working Pressure bar (PSI). (2) Line Speed, first layer MPM (FPM) vs. flow LPM (GPM).

HYDRAULIC SYSTEM REQUIREMENTS

1.

Motor spool (open center) control valve

2.

Emergency Stop:

A. If winch is controlled by a direct-operated manual valve, that valve serves as the E-stop.

B. If a remote operated control valve is used, a solenoid-operated hydraulic dump valve, normally open to

tank, and an emergency stop switch (to open the dump valve) is required. The E-stop switch is to be

normally closed and have a red, resettable push button actuator with a yellow background. The E-stop

switch must be easily accessible to the operator.

3.

Relief valve set to 172,4 bar (2500 psi) which is the rated capacity limiter.

4.

Flow rate of 56,7 LPM (15 GPM) maximum. Do not exceed 75,7 LPM (20 GPM) or motor and winch may be damaged.

5.

Hydraulic fluid with a viscosity between 20-43 cSt (100-200 SUS). Maximum operating temperature 85C (180F).

Cleanliness level of ISO 17-14 or better.

(RATED CAPACITY LIMITER)

172,4 bar (2500 PSI)

56,7 LPM (15 GPM)

19 mm (.75 in) I.D. MINIMUM

I.D. MINIMUM

12,7 mm (.50 in)

TYPICAL LAYOUT

PUMP

LOW PRESSURE LINE

HIGH PRESSURE LINE

RATED LOAD:

PRESSURE AT

MAX. FLOW &

(MOTOR SPOOL)

4 WAY VALVE

3 POSITION

172,4 BAR (2500 PSI)

SYSTEM RELIEF

PORT

BRAKE

MOTOR

WITH BRAKE RELEASE SHUTTLE

DUAL-A & B PORT CONTROL

PROVIDED BY USER

DUMP VALVE

*

*

E-STOP SWITCH

REQUIRED ONLY IF REMOTE-OPERATED CONTROL VALVE IS USED. SEE 2B

*

IN HYDRAULIC SYSTEMS REQUIREMENTS. NOT REQUIRED FOR A

DIRECT-OPERATED MANUAL VALVE.

WORKING PRESSURE bar (PSI) AT 56,7 LPM (15 GPM)

FLOW LPM (GPM)

LI

N

E

P

U

LL

-F

IR

S

T

L

A

Y

E

R

k

N

(

lb

)

LI

N

E

S

P

E

E

D

-F

IR

S

T

L

A

Y

E

R

M

P

M

(

F

P

M

)

0

18,9

37,9

56,7

3,1 (10)

6,1 (20)

9,2 (30)

12,2 (40)

0

0

4,4 (1000)

8,9 (2000)

13,3 (3000)

17,8 (4000)

22,2 (5000)

26,7 (6000)

31,1 (7000)

34,9 (7840)

68,9

137,9

172,4

15,2 (50)

BASED ON 254 cc (15.5 cu in) MOTOR

103,4

34,5

PERFORMANCE CHARTS

(0)

(5)

(10)

(15)

(0)

(1000)

(2000) (2500)

(1500)

(500)

7