Winch mounting, Rope installation – Ramsey Winch HD-P 34,9 User Manual

Page 5

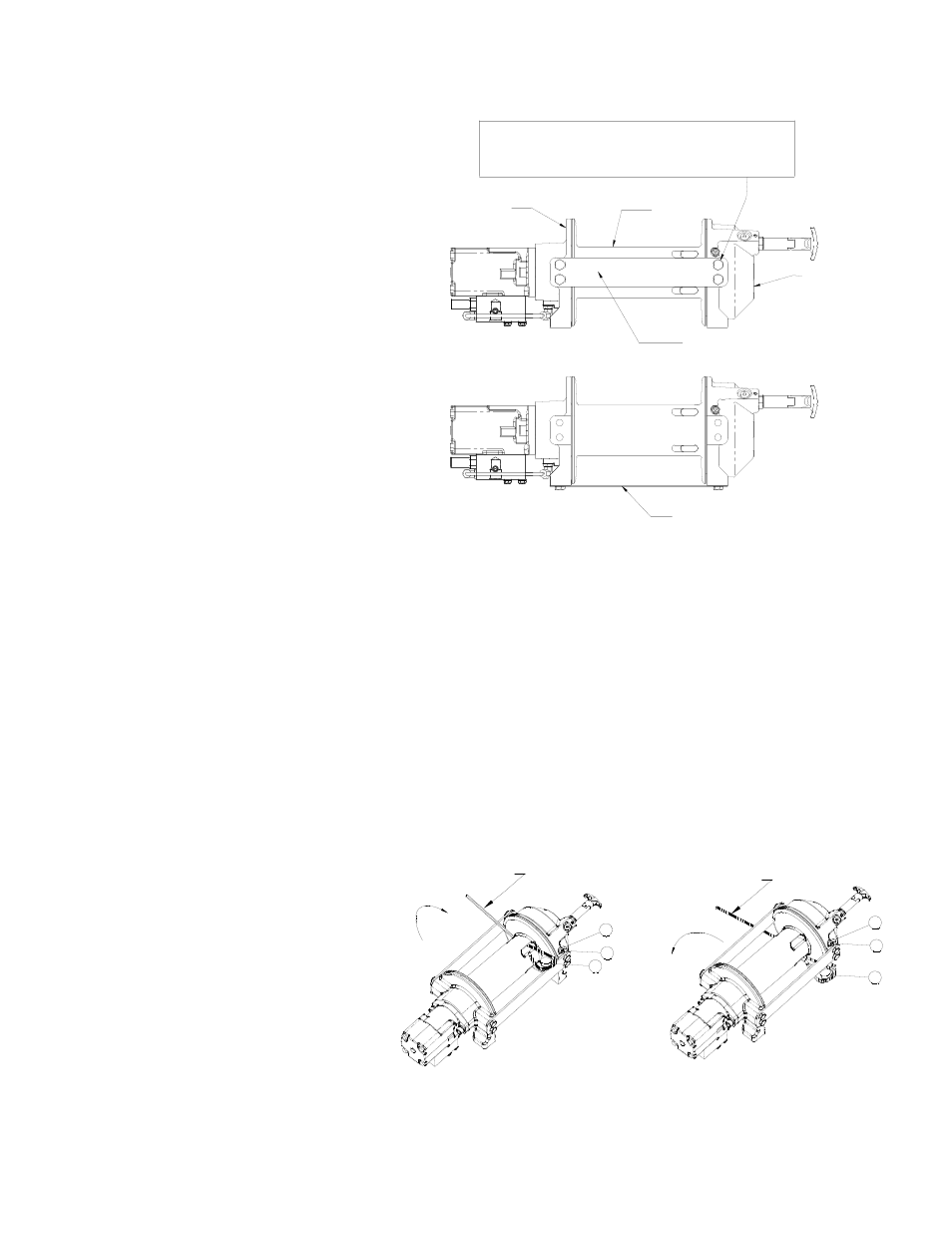

WINCH MOUNTING

ESSENTIAL MOUNTING INSTRUCTIONS TO MAINTAIN

ALIGNMENT OF PLANETARY WINCH COMPONENTS:

I

t is most important that this winch be mounted securely so that

the three major sections (the motor end, the rope drum, and the

gear housing end) are properly aligned. Excessive bushing wear

and difficulty in freespooling are usually symptoms of

misalignment.

In the as-installed condition, if the winch is mid-mounted, then

at least one tie-plate must be attached to the mounting feet at

the bottom of the winch to maintain alignment. If the winch is

foot mounted then at least one tie-plate must remain mounted at

midpoint of winch to maintain alignment. It is always preferred

to used BOTH tie-plates in the final installed configuration.

Angle Mounting Kit, P/N 251006 (for Std. Drum) or 251007 (for

“Y” drum), is recommended for maximum ease in mounting the

winch. The angle kit will allow the winch to be mounted in

upright or midmount applications and will meet the criteria of

serving as a solid and true mounting surface.

When mounting the winch with other than the recommended

Ramsey Angle Kit, the mounting hole patterns described in the

Dimensional drawings on pages 11-13 should be used. The

mounting surface must be flat within 0,38 mm (.015 in) and

sufficiently stiff to resist flexing. If a steel plate is used for foot

mounting, it should be 19,05 mm (.75 in) thick. For this

mounting application eight (8) 1/2-13NC x 1-1/2” long grade 5

capscrews with lockwashers will be needed to mount winch. Capscrews should be tightened to 115 Nm (85 ft-lb) torque.

NOTE: If angles or a steel plate are used in mounting winch, tie-plates provided with winch are to be attached to the remaining mounting

pads, whether they be side or foot.

ROPE INSTALLATION

An “A” or “B” decal on the clutch end bearing indicates the spooling direction of the rope. Also, a letter “A” or “B” is stamped in the end

bearing on the clutch end indicating rotation direction. If the decal is damaged or unreadable, contact Customer Service for additional

instructions to determine proper direction. To reverse the rotation direction, exchange positions of the cartridge and plug shown on

page 5.

1. Unwind rope by rolling it out along the ground

to prevent kinking. Securely wrap end of

rope, opposite hook, with plastic or similar

tape to prevent fraying.

2. Slide the wire rope through narrow end of the

pocket against the drum flange. Wrap the

wire rope around on the anchor “puck” (item

#19) and pull the wire rope and anchor back

into the wide end of the pocket. Use a soft

hammer to drive the back side of the wire

rope, firmly seating the wire rope and anchor

into the pocket.

3. Carefully run winch in the "reel-in" direction.

Keeping tension on end of rope, spool all the

rope onto the rope drum, taking care to form

neatly wrapped layers.

After installing rope, check freespool

operation. Disengage clutch and pull on rope

at a walking speed. If rope “birdnests”,

loosen jam nut (item #20) and turn nylon

setscrew (item #17) clockwise to increase drag on drum. If rope pull is excessive, loosen nylon setscrew by turning counterclockwise.

Tighten jam nut when proper setting is obtained.

CAUTION: OVER-TIGHTENING OF JAM NUT MAY STRIP NYLON SETSCREW.

5

MOTOR END

ROPE DRUM

GEAR HOUSING END

TIEPLATE AT SIDE LOCATION

TIEPLATE AT FOOT (BASE) LOCATION

CAUTION: If longer bolts (minimum grade 5) are substituted to mount winch or to

mount a roller guide at the side mount pads, bolt length must be such as to allow a

minimum of 12,7mm (.50 in) thread length engagement in the tapped holes in side of

each end bearing. Use of excessive length bolts will damage the winch and prevent

freespool of the drum. Torque bolts to 75 Nm (55 ft-lb).

.

FOOT MOUNT

MID MOUNT

"A" ROTATION

DIRECTION

TO REEL IN

INSERT ROPE AS SHOWN FOR "A" ROTATION

OVERWOUND APPLICATION.

20

17

17

20

INSERT ROPE AS SHOWN FOR "B" ROTATION

(UNDERWOUND APPLICATION)

"B" ROTATION

DIRECTION

TO REEL IN

19

19