Ramsey Winch RPH-12000 User Manual

Page 13

11

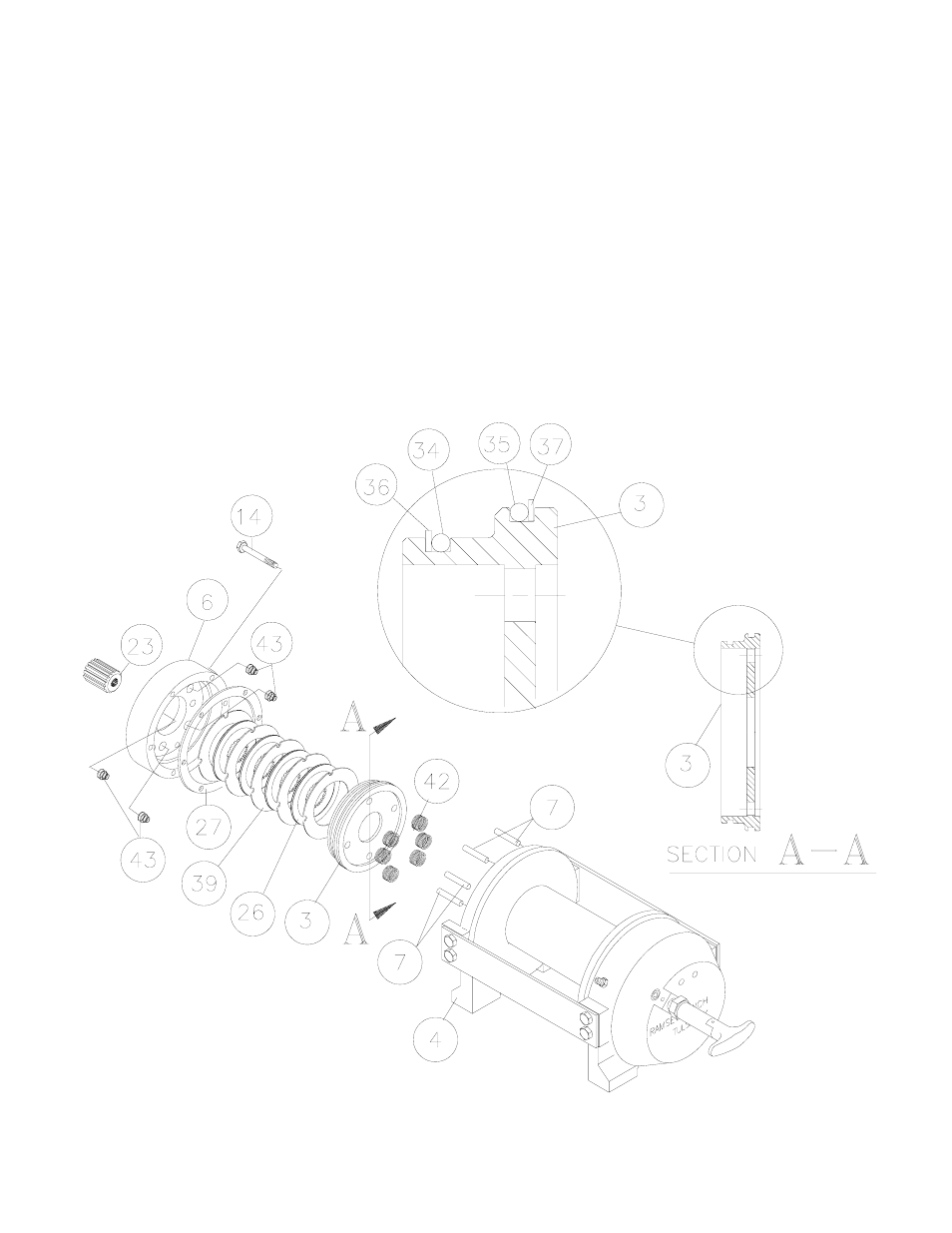

Set winch on gear housing end with motor end bearing (item #4) up. Insert (6) springs (item #42) into pockets of

motor end bearing (item #4), as shown, leaving top and bottom pockets empty. Install coupling (item #23) over

splined end of shaft (item #8). Put (4) brake pins (item #7) into (4) holes in motor end bearing. Install well-oiled o-

ring (items #34 & #35) and backup rings (items #36 & #37) into grooves in O.D. of piston (item #3). Place o-rings

into portions of grooves nearest to center of piston in both cases. See SECTION A-A below.

Piston (item #3), brake disc (item #26) and separator plates (item #39) must be clean and free of grease and oil.

Place piston over pins (item #7) and on top of springs (item #42). Place separator plates (item #39) and brake disc

alternately on top of piston, as shown below. Press larger diameter end of (4) springs (item #43) into pockets in

brake housing (item #6). Place gasket (item #27) on top of end bearing (item #4). Place brake housing over brake

parts with fitting ports downward toward mounting feet. Align mounting holes and force brake housing down onto

end bearing (item #4). Apply 271 Loc-tite to 6 capscrews (item #14) and finger tighten until flush with surface of

brake housing. Torque capscrews (2 turns each) in a criss-cross pattern until a torque of 30 ft. lbs., per capscrew, is

achieved.