Ramsey Winch HD-P10000 User Manual

Page 8

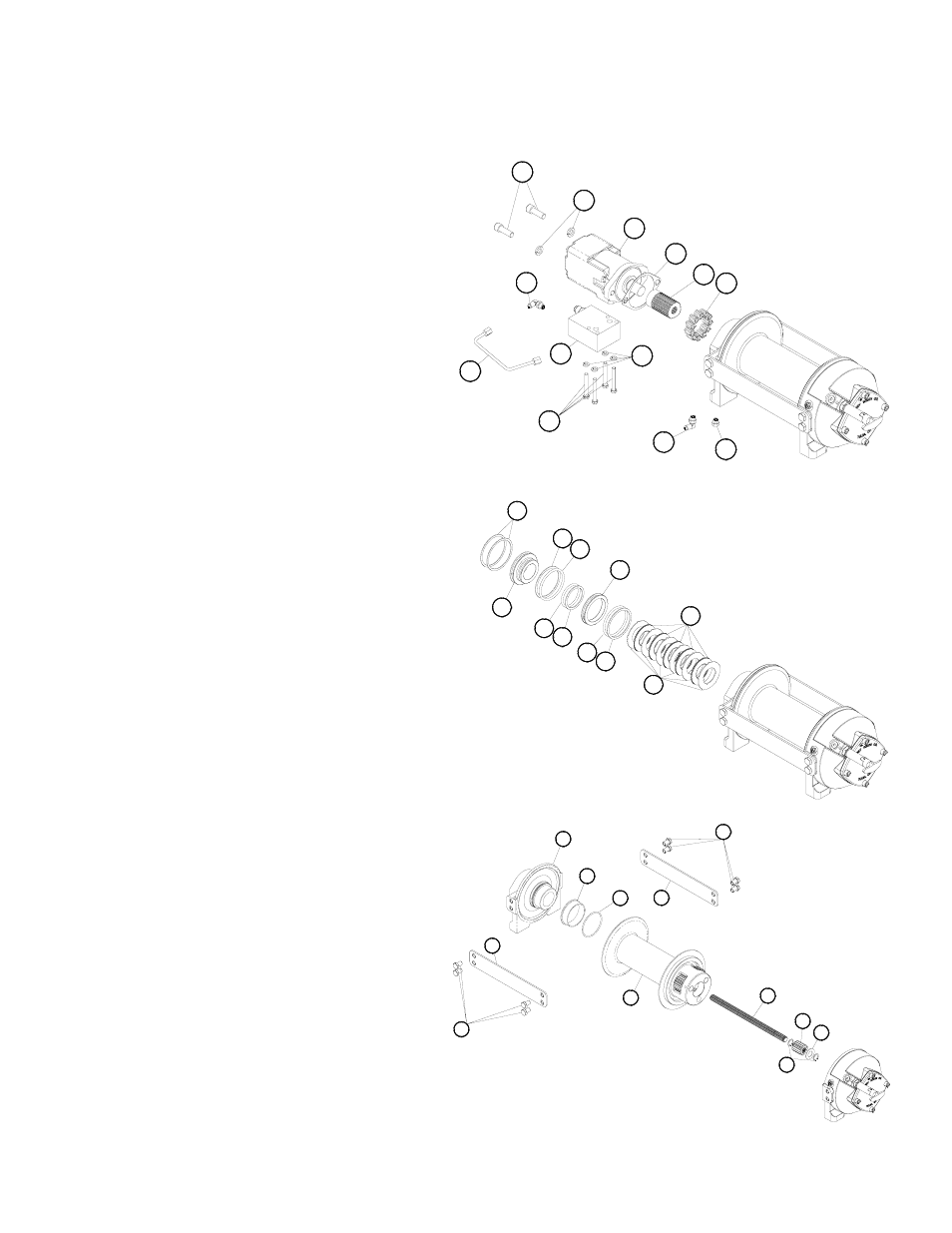

INSTRUCTIONS FOR OVERHAUL HD-P10000 SERIES WINCH

Take note of mounting configurations for proper mounting of parts during re-assembly. Replace all gaskets, o-rings,

and seals during re-assembly.

Disconnect tube (item #44) from elbow fittings (items

#26) on bottom of end bearing and counterbalance valve

(item #45). Remove motor (item #30) from end bearing

by slowly unscrewing capscrews (items #19). CAUTION:

MOTOR IS UNDER SPRING PRESSURE.

Check breather vent (item #48). Make sure it is not

clogged. If oil is leaking from vent, check brake o-rings,

backup rings, and sealing surfaces (see page 8).

Remove springs (items #43) from pockets and inspect for

damage.

Replace gasket (item #28).

Remove coupling (item #25) from end bearing. Examine

coupling for signs of wear, replace if necessary. If neces-

sary, remove counterbalance valve from motor by remov-

ing capscrews (items #15).

Remove retaining rings (items #42) with screwdriver.

Remove brake parts from end bearing. NOTE POSITION OF

O-RINGS AND BACKUP RINGS BEFORE REMOVAL. Examine

brake discs (items #5) and stators (items #4) for signs of

wear, and replace if necessary.

Examine o-rings (items #31 and 32) and backup rings

(items #34 and 36) in brake piston (item #6), as well as o-

ring (item #33) and backup ring (item #35) in backup brake

piston (item #7) for signs of wear. Remove o-rings and

backup rings from grooves in brake piston or backup brake

piston and replace if necessary.

Remove tie plates (items #12) from end bearings by

unscrewing capscrews (items #16). Slide motor end

bearing (item #10) and drum (item #1) from gear hous-

ing end bearing.

Remove input shaft (item #11) from end bearing. Inspect

shaft and and output sun gear (item #8) for damage and

replace if necessary. To remove the output sun gear,

remove the snap rings (items #41) and thrust washer

(item #47) and pull off the end of the shaft.

Remove bushing (item #14) and o-ring (item #37) from

motor end bearing. Place new, well-oiled o-ring into

groove inside of end bearing and press new bushing onto

end bearing.

43

44

26

45

23

15

26

25

28

30

24

19

48

8

5

4

35

33

7

31

36

32

34

6

42

14

37

10

41

47

8

11

1

12

16

12

16