Ramsey Winch HD-P10000 User Manual

Page 10

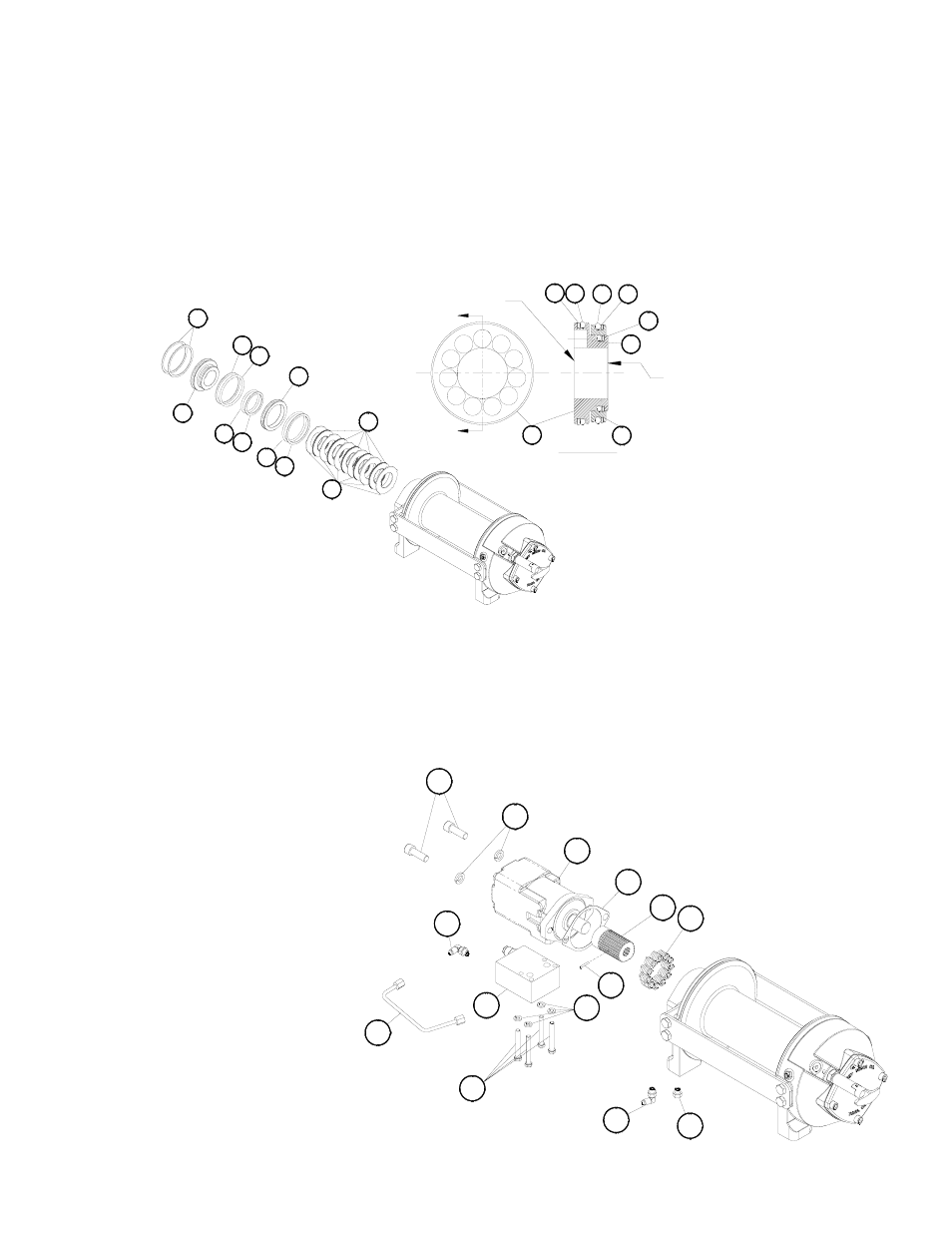

Set winch with gear housing end down on work surface.

Install well-oiled o-rings and backup rings into grooves on outside of brake piston and backup brake piston as shown in cross-

section A-A below.

Piston, backup piston, brake discs and stators must be clean and free of grease and oil.

Insert brake discs (item #5) and stators (item #4) into gear end alternating, with stators first and last.

Insert backup brake piston (item #7) into motor end and insert brake piston (item #6) into it. Apply even pressure on piston

when installing.

Install retaining rings (item #42) into grooves in motor end housing.

Insert springs (item #43) into pockets in back of brake piston.

Install roll pin (item #38) into new motor coupling below bottom of spline teeth. Insert motor coupling (item #25),

engaging it with the discs and the input shaft.

Place gasket (item #28) on mounting surface of motor (item #30). Slide motor shaft into coupling. Attach motor to motor end

bearing housing using (2) capscrews (item #19) and (2) lockwashers (item #24). Evenly tighten to 49 ft-lbs. (66 Nm) torque.

Install the counterbalance valve (item #45) to the motor using (4) capscrews (item #15) and (4) lockwashers (item #23).

Tighten to 17 ft-lbs (23 Nm).

Securely connect fittings (item #26) to motor

end housing and counterbalance valve, and

connect tube assembly (item #44) to fittings.

Apply at least 550 PSI hydraulic system pres-

sure to brake and verify that brake releases

(winch drum will rotate).

SECTION A-A

A

A

5

4

35

33

7

31

36

32

34

6

42

DRUM SIDE

MOTOR SIDE

36

31

35

33

32

34

7

6

10

26

26

44

48

43

45

23

15

25

28

30

24

19

38