Operation – Lincoln Electric IM10085 ACTIV8 User Manual

Page 22

B-3

OPERATION

B-3

ACTIV8™

1. WIRE FEED SPEED KNOB

Use the Wire Feed Speed Knob to adjust the rate

of wire feed speed.

WFS range:

50 to 800 ipm

Because the wire feeder is powered by the arc

voltage, the full range of wire feed speed may not

be available at low voltages.

(See Customer Assistance Policy in the front of this

Instruction Manual)

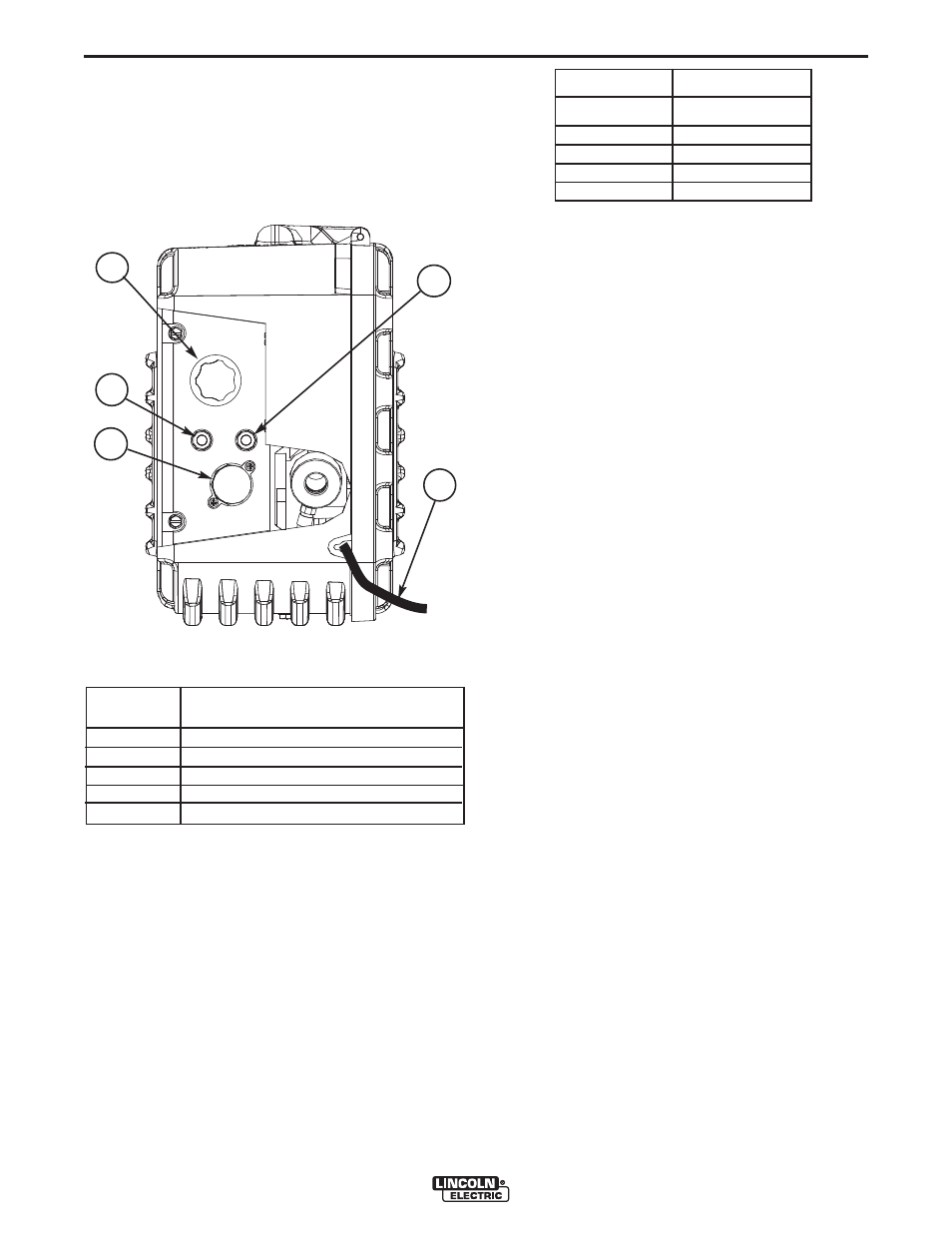

CASE FRONT CONTROLS

(See Figure B.1)

ITEM DESCRIPTION

1

Wire Feed Speed Knob

2

5-pin gun trigger connector

3

Work lead

4

Thermal LED

5

Polarity LED

1

3

5

2

4

FIGURE B.1

Arc Voltage

Max WFS

15V

440 ipm

18V

523 ipm

21V

609 ipm

24V

690 ipm

27V

783 ipm

See “Constant Current Operation” for setting

the Wire Feed Speed when in the CC mode.

2. TRIGGER CONNECTOR

There is one circular connector for the gun trigger

on the front of the ACTIV8™. Note – if the gun

trigger is already depressed when the feeder is

powered up, the feeder will not activate. Release

and then press the gun trigger to begin welding.

3. WORK LEAD

Always turn power off at the welding power source

before moving the work lead.

The work lead attaches to the item being welded.

4. THERMAL LED, MOTOR OVERLOAD

The thermal LED illuminates when the wire drive

motor draws too much current. If the thermal light

illuminates, the wire drive will automatically shut-

down for up to 30 seconds to allow the motor to

cool. To start welding again, release the gun trig-

ger, inspect the gun cable, liner (and conduit).

Clean and make repairs as necessary. Start weld-

ing again when the problem has been safely

resolved.

For best results, keep the gun cable and conduit

as straight as possible. Perform regular mainte-

nance and cleaning on the gun liner, conduit and

gun. Always use quality electrode, such as L-50

or L-56 from Lincoln Electric.

5. POLARITY LED

The polarity LED illuminates when the wire feeder

is connected to positive polarity.