Installation, Warning – Lincoln Electric IM10085 ACTIV8 User Manual

Page 14

A-5

INSTALLATION

ACTIV8™

A-5

PRESSURE ARM ADJUSTMENT

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the weld-

ing power source before installation or

changing drive rolls and/or guides.

• Do not touch electrically live parts.

• When inching with the gun trigger, electrode

and drive mechanism are "hot" to work and

ground and could remain energized several sec-

onds after the gun trigger is released.

• Do not operate with covers, panels or guards

removed or open.

• Only qualified personnel should perform mainte-

nance work.

------------------------------------------------------------------------

The pressure arm controls the amount of force the

drive rolls exert on the wire. Proper adjustment of the

pressure arm gives the best welding performance.

Many welding problems can be attributed to setting

the pressure arm too high and causing wire deforma-

tion. Set the pressure arm to minimum amount that

provides reliable feeding.

Set the pressure arm as follows:

Cored wires

between 1 and 3

Steel, Stainless wires

between 3 and 5

WARNING

LOADING SPOOLS OF WIRE

• Keep hands, hair, clothing and tools

away from rotating equipment.

• Do not wear gloves when threading wire

or changing wire spool.

• Only qualified personnel should install, use or

service this equipment.

------------------------------------------------------------------------

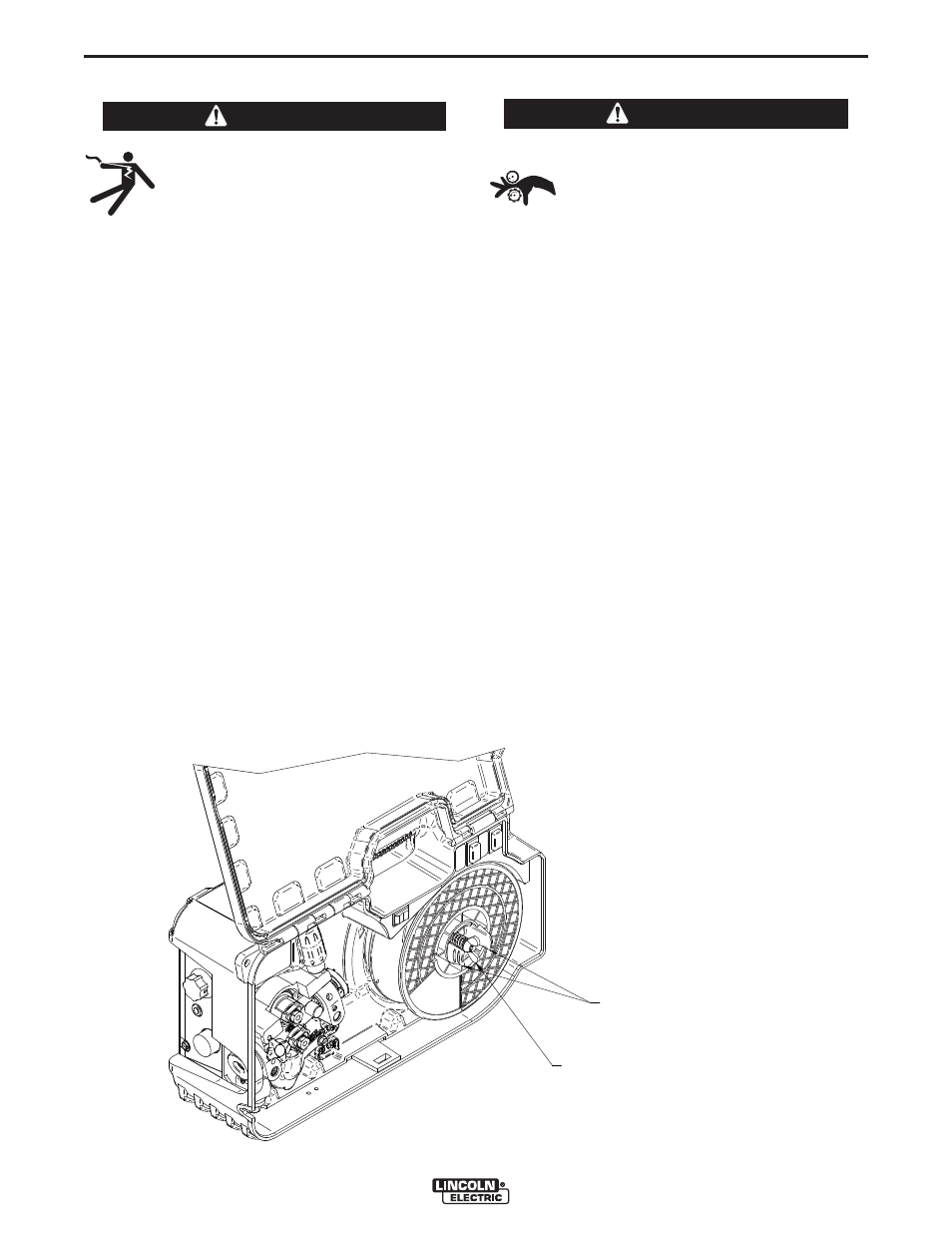

SPOOL RETAINER

When loading and removing the 8” spools make sure

that the wing nut (inside the wire reel spindle hub) is

turned 90° from the wire reel spindle locking tabs. If

the wing nut is positioned in line with the locking tabs,

the tabs cannot be depressed to load or unload the

wire spool. (See Fig A.2)

The wire spool must be pushed all the way on the

spindle so that both the spindleʼs tabs will hold it in

place. The wire spool will rotate counter clockwise

when wire is de-reeled.

SPOOL BRAKE

Adjust the spool brake with wire spool installed, to

provide enough friction to stop wire overrun. To

adjust the brake turn the wing nut clockwise to

increase the brake, and counterclockwise to loosen

the brake.

Excessive brake force may cause motor thermal over-

loads or welding problems.

WARNING

WING NUT

WIRE REEL SPINDLE

MOUNTING TABS

FIGURE A.2