Vestil FTLP-5454 User Manual

Page 7

10/21/2010

rev. 10/22/2010

FTLP manual, operation instructions.doc

Step 3: Load the platform

The fork truck operator and bystander(s) might sustain serious personal injuries or could be killed if the

platform is misused. Disregarding obvious hazards constitutes product misuse.

To reduce the likelihood of harmful

consequences:

FTLP-series products are medium-duty rated platforms. Therefore,

ONLY use the platform with sit-down rider high lift fork trucks having

a maximum rated load of at least 3,000 pounds at a 24in. load

center.

ALWAYS review the “Safety Guidelines” on p. 3 before each use.

Apply ANSI/ITSDF B56.1-2005, “Safety Standard for Low Lift and

High Lift Trucks,” suggestions regarding the use of fork-mounted

platforms. The publication is freely downloadable:

http://www.itsdf.org/pB56.asp

When raised 4 feet (~1.2m) or higher, guard rails are required if

any person must occupy the platform to load/unload equipment. Do

not lean against the handrails or safety chains. NO person should

occupy the platform during load transport. Maximum occupancy is 2

persons.

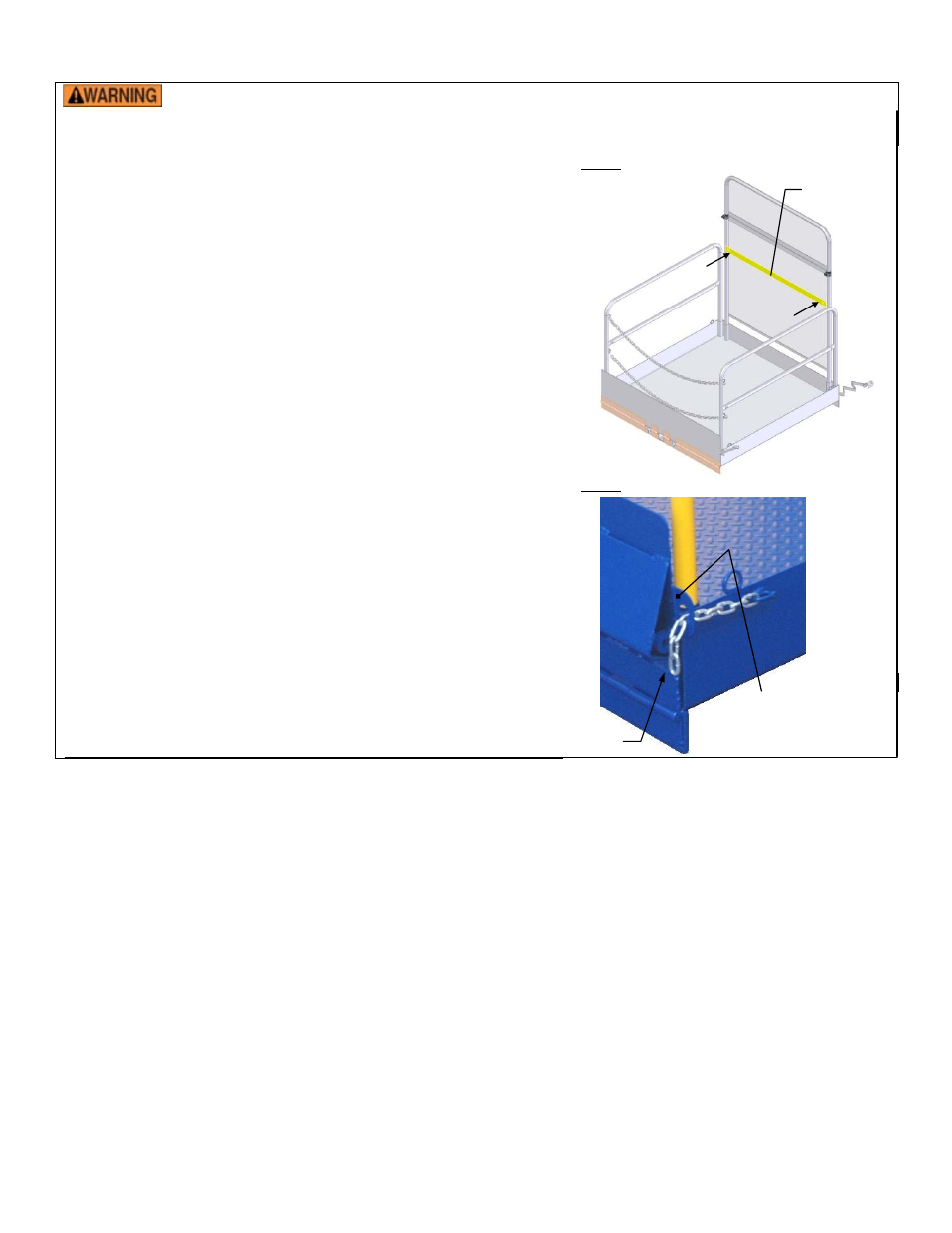

If work site practice requires that any person who occupies an

elevated platform must wear a safety harness and lanyard, only 1

person should connect to a given anchorage point. Anchorage

points are present at each end of the anchorage weldment (see

arrows in FIG. 6). NO person should occupy the platform during load

transport. Maximum occupancy is 2 persons.

Only use the platform on smooth, level, finished surfaces capable of

supporting the combined weight of the person(s) occupying the

platform and all equipment and/or material present on the platform,

the platform itself, the lift truck and operator.

Avoid sudden stops or quick turns while transporting the platform.

DO NOT drive the fork truck while the platform is occupied. If it

is necessary to reposition the fork truck or to relocate the platform,

fully lower the forks, require all persons to disconnect safety lanyards

and dismount the platform.

Set the parking brake before lifting the platform.

FIG. 6: Anchorage

Points (arrows)

Anchorage

weldment

Before transporting the platform, secure it to the (fork truck) mast.

Inspect the platform for signs of damage, and verify that the ramp

closure mechanism functions properly as shown in FIG. 7.

FIG. 7: Ramp Closure Mechanism

Closure plate

Closure

chain

Load equipment onto the platform:

1. Pull upwards on the free end of the closure chain (see Fig. 7 above) pull the chain through the opening in the closure

plate;

2. Lower the ramp;

3. Center the load/equipment on the platform;

4. Secure the load to the platform with tie-down straps or equivalent means. Attach the ends of the straps to the tie-

down D-rings (see FIG. 5 on p. 6). Make sure that the load is immobilized and secured to the platform.

5. Raise the ramp and secure it with the closure chain. Lift the platform only as high as necessary to avoid contact with

obstacles present along the path of travel. Transport the load to the desired location.

6. Adjust the elevation of the platform so that it rests on the surface that will receive the load/equipment (the bed of a

truck, for example). Make sure that the platform is level; adjust the tilt of the mast if necessary to level the platform.

Lower the ramp and release the tie-down straps. Transfer the equipment/load to the truck or other surface.

7. Raise the ramp and secure it with the closure chain; then return the platform to its storage location.

p. 7 of 8

Copyright 2010 Vestil Manufacturing Corp.