Afety, Uidelines – Vestil FTLP-5454 User Manual

Page 3

10/21/2010

rev. 10/22/2010

FTLP manual, operation instructions.doc

Failure to read and understand the instructions included in this manual before

using or servicing the work platform constitutes misuse of the product.

Study the entire manual before you use the product for the first time and before each subsequent use. Read the

manual to refresh your understanding of the safe use, inspection and maintenance procedures explained on p. 5. If

questions remain about the product after you finish reading the manual, contact Vestil for answers. DO NOT attempt to

resolve any problems with the work platform unless you are authorized to do so and are certain that it will be safe to use

afterwards.

S

AFETY

G

UIDELINES

Electrocution might result if the platform contacts electrified wires. Reduce the likelihood of electrocution by

applying common sense:

DO NOT contact electrified wires with any part of the platform;

DO NOT use the platform in an area where contact with electrified wires is likely;

DO NOT use the platform close to electrified wires or other sources of electricity;

Before using the platform, always inspect the usage area for unusual conditions that require special precautions.

Material handling is dangerous. Improper or careless operation might result in serious personal injuries

sustained by the fork truck operator, platform occupant, and/or bystanders. Apply to the following suggestions to reduce

the likelihood of injury (unless law compels different action(s)):

Contact the manufacturer of your lift truck to verify that the truck is capable of safely handling the fully loaded platform.

To calculate the weight of a “fully loaded platform,” select the specific model you own/use, find the net weight of your

model in the table above, and then add 2,000 pounds (909kg). The width of your platform must be equal to or less

than the width of your fork truck plus 10 inches (250mm).

ONLY use the platform as a means for lifting and transporting equipment NOT people.

DO NOT use a structurally compromised platform. Examples of structural damage includes: broken/severely damaged

railings, mast guard, or fork pockets, and holes produced by rust or corrosion in the platform floor. Inspect the platform

before each use according to the inspection instructions on p. 3-4. DO NOT use the platform unless it passes every

part of the inspection.

DO NOT use the platform if the safety strap is damaged or missing; DO NOT lift the platform until it is securely

connected to the carriage of the fork truck with the safety strap (see Step 1 & 2 on p. 6).

DO NOT attempt to lift a load that weighs more than the maximum load rating of the platform. The net weight, i.e. the

combined weight of everything supported by the platform including any person supported by the platform while loading

or unloading equipment, cannot exceed the maximum rated load of the platform.

DO NOT stand beneath or travel under the platform while it is elevated.

DO NOT use the chains, mast guard, or guardrails as a step.

DO NOT use the platform to transport people! A person should only stand or walk on the platform to load and unload

equipment.

DO NOT use the platform UNLESS each label shown in Fig. 8 on p. 8 is affixed to the platform, undamaged and

readable.

Inspections & Maintenance

Before each use inspect the listed components:

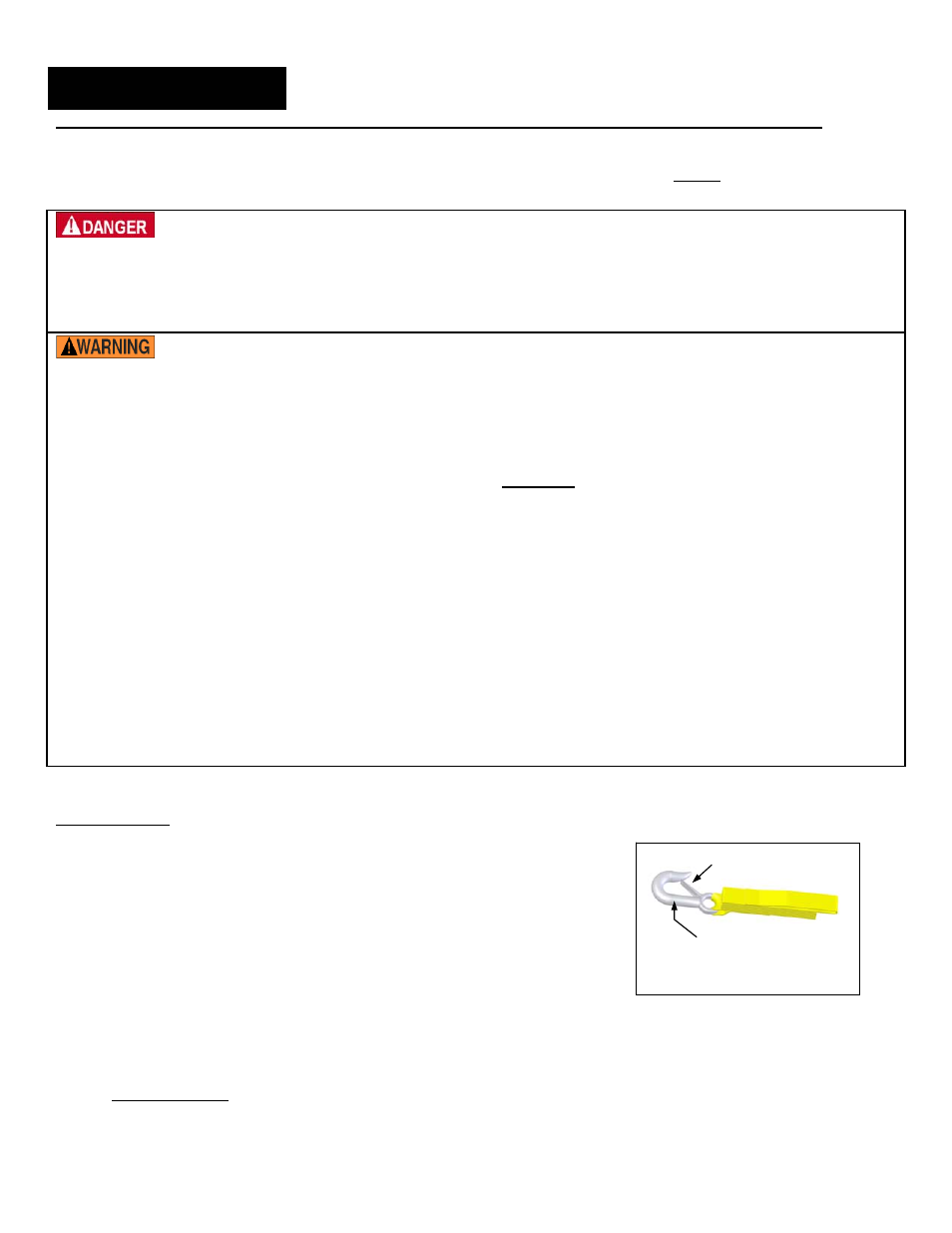

1. Snap hook (attached to the free end of the nylon safety strap): confirm that

the spring latch automatically closes securely against the tip of the hook as

shown in the diagram to the right. If the hook, nylon strap, or latch is

damaged, then do not use the platform until a complete, new safety strap is

obtained and attached to the platform. Refer to steps 1 & 2 on p. 6 for

attachment procedures.

Nylon safety strap (item no. 1

on p. 4)

spring

latch

hook

2. [FTLP-5454-HR]

Handrails: check the rails, rail welds, and points of contact

between the rails and the sleeves welded to the platform for bending,

warping and cracking.

3. [FTLP-5454-HR]

Lanyard

attachment

points: check the anchorage weldment

(see FIG. 6 on p. 7) and points of attachment to the mast guard for bending,

warping, or cracking.

4. Product labels: all labels should be readable and located as shown in the diagram on p. 8. If a label(s) is unreadable

or missing, contact Vestil to order a replacement.

At least 1 time per month, inspect:

1. Fasteners (hardware):

Mast guard hinge - bolts, nuts, washers. Replace all damaged fasteners.

Gate – chains, snap hooks, welded D-rings (attachment points for each chain). DO NOT use the platform

until all damaged hooks and chains are replaced and damaged D-rings are restored to original condition.

p. 3 of 8

Copyright 2010 Vestil Manufacturing Corp.