Operating instructions – TIF 5650A Halogen Leak Detector User Manual

Page 7

OPERATING INSTRUCTIONS

5

This mode should be used to initially find a leak. Upon receiving an alarm (a

rapid increase in signal) the leak can be more precisely located by switching

to NORMAL (ON) mode (Right hand switch position). The beeping rate (in

fresh air) will return to its normal, slower rate. Follow the instructions for leak

detection as described in the next section.

OPERATION (ALL MODELS):

1. Turn unit on by moving the power switch to the "ON" position.

2. The unit will begin to beep at a slow steady rate. Allow the unit to

stabilize for five or six beeps and then begin searching for leaks.

3. MODEL 5750A ONLY: Begin leak checking in the SCAN mode. Switch

to NORMAL (ON) sensitivity if needed as described above.

Leak Detection Techniques

NOTE: On Automotive A/C Systems leak test with the engine not in

operation.

1. The air conditioning or refrigeration system should be charged with

sufficient refrigerant to have a gauge pressure of at least 340 kPa

(50 psi) when not in operation. At temperatures below 15° C (59° F),

leaks may not be measurable, since this pressure may not be reached.

2. Take care not to contaminate the detector probe tip if the part being

tested is contaminated. If the part is particularly dirty, or condensate

(moisture) is present it should be wiped off with a dry shop towel or

blown off with shop air. No cleaners or solvents should be used,

since the detector may be sensitive to their ingredients.

3. Visually trace the entire refrigerant system, and look for signs of air

conditioning lubricant leakage, damage, and corrosion on all lines,

hoses, and components. Each questionable area should be carefully

checked with the detector probe, as well as all fittings, hose to line

couplings, refrigerant controls, service ports with caps in place,

brazed or welded areas, and areas around attachment points and

hold-downs on lines and components.

4. Always follow the refrigerant system around in a continuous path so

that no areas of potential leaks are missed. If a leak is found, always

continue to test the remainder of the system.

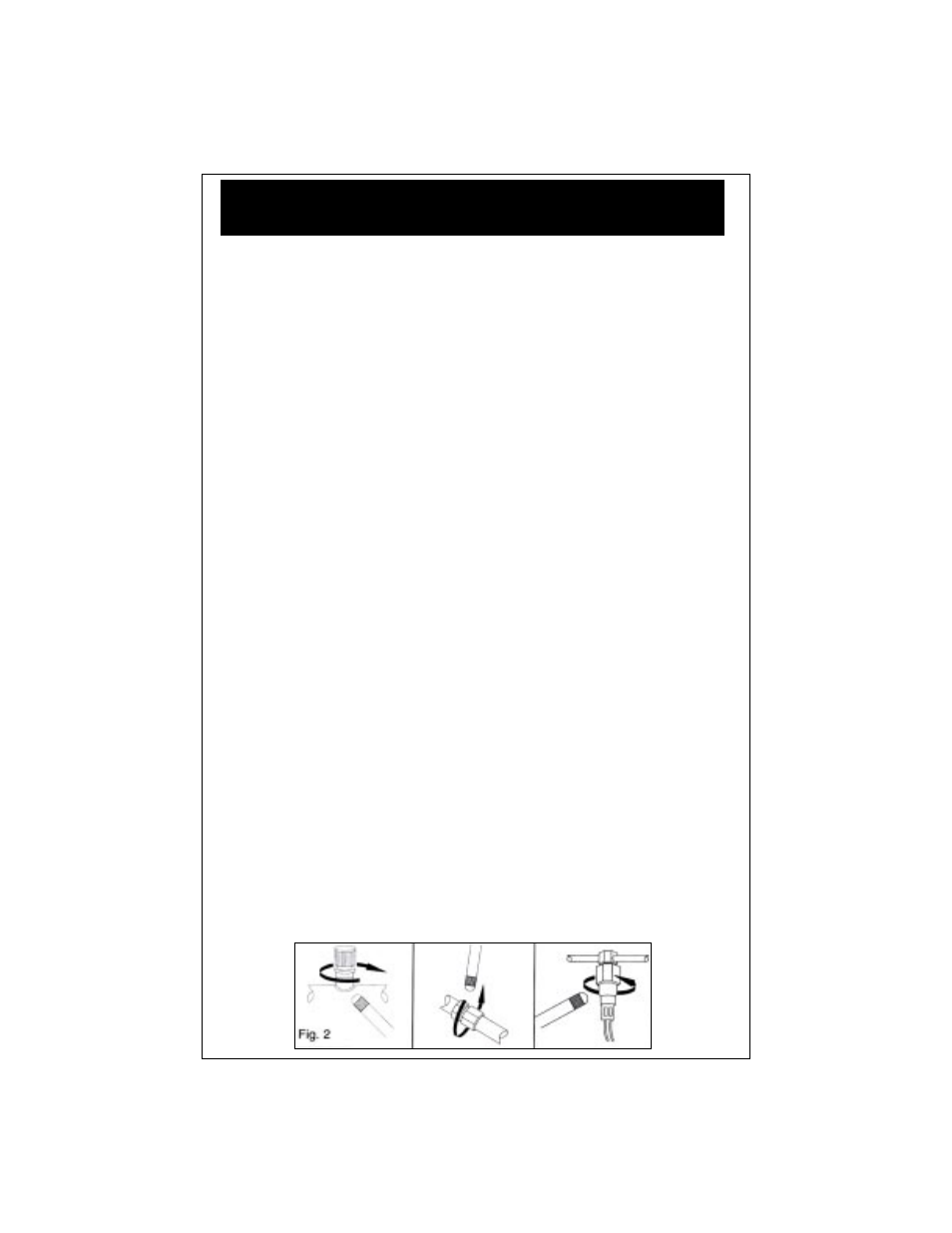

5. At each area checked, the probe should be moved around the

location, at a rate no more than 25 to 50 mm/second (1-2 in/second),

and no more than 5 mm (1/4 in) from the surface, completely around

the position. Slower and closer movement of the probe greatly

improves the likelihood of finding a leak (see Fig. 2, below). Any

increase in beep rate is indicative of a leak.