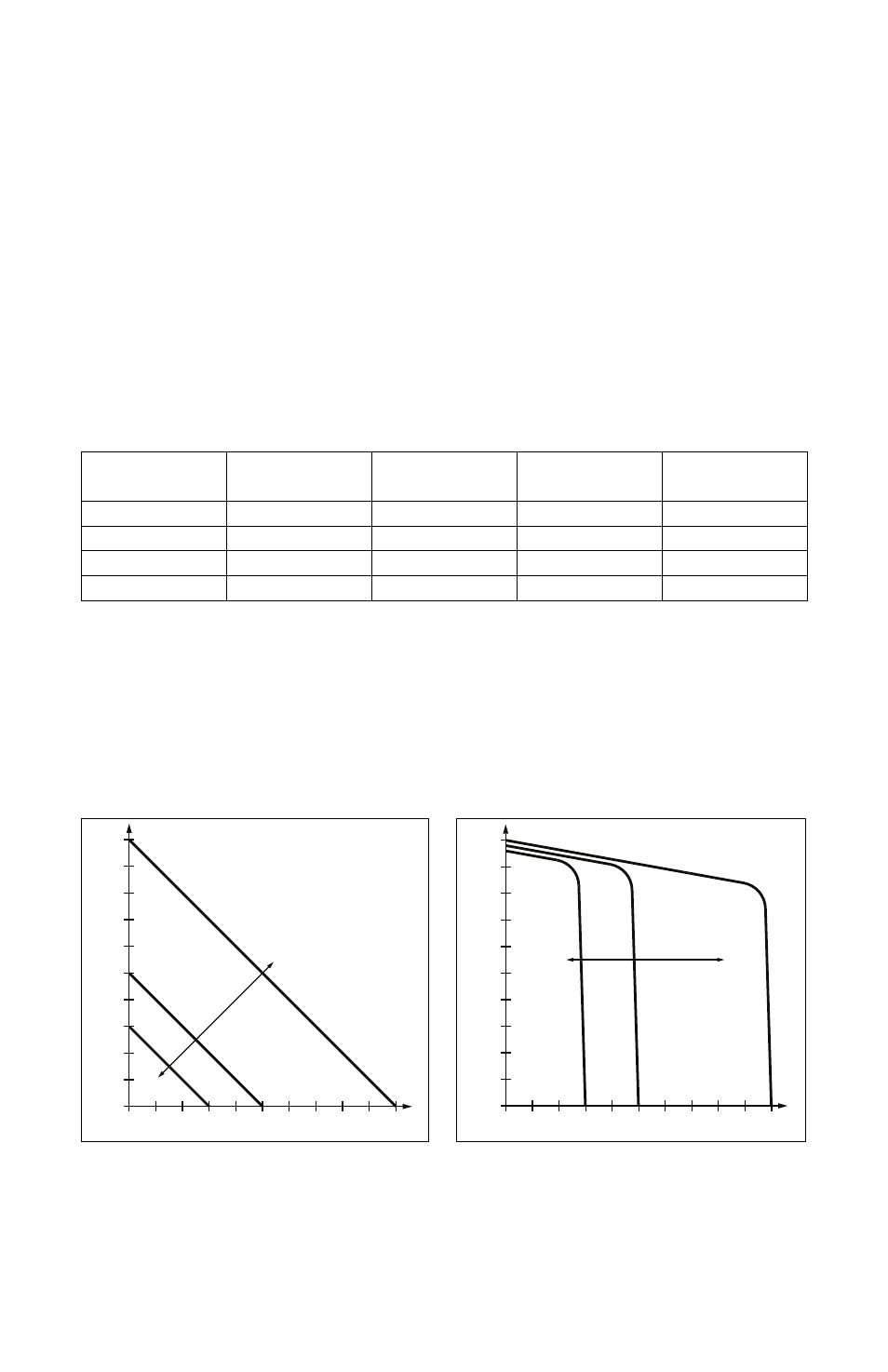

Figure 29 – linear torque mode, Figure 30 – non-linear torque mode – KB Electronics KBRC-240D User Manual

Page 18

C. The hi-pot test voltage should be set in accordance to the testing agency standards and

the leakage current should be set as low as possible without causing nuisance trips.

D. To eliminate motor speed control damage due to auxiliary equipment hi-pot failure, it is

also recommended that all signal inputs be wired together and connected to the AC input

lines as shown.

VI. OPERATION

After the KBRC-240D has been properly setup (jumpers set to desired positions and wiring

completed), the startup procedure can begin. If AC power has been properly brought to the

control, the ON and STOP LEDs will be illuminated. Before starting, be sure that the Main

Speed Potentiometer is set to the zero speed position. To start the control, momentarily set

the Start/Stop Switch to the “START” position. The STOP LED should no longer illuminate.

The motor should begin to run as the Main Speed Potentiometer is rotated.

Note: If the motor runs in the incorrect direction, it will be necessary to disconnect the AC

line, reverse the motor leads and repeat the startup procedure.

Linear Torque Mode:

In Linear Torque mode (Jumper J7 set to the “S/L” position), speed and torque vary linearly

as a function of Main Speed Potentiometer rotation or input signal. See Figure 29.

Non-Linear Torque Mode:

In Non-Linear Torque mode (Jumper J7 set to the “NL” position), the torque is varied by the

Main Speed Potentiometer or input signal, and remains constant throughout the motor’s

entire speed range. See Figure 30.

VII. AC LINE FUSING

The KBRC-240D does not contain AC line fuses. Most electrical codes require that each

ungrounded conductor contain circuit protection. It is recommended to install a 20 Amp fuse

(Littelfuse 326, BUSS ABC or equivalent) or a circuit breaker in series with each unground-

ed conductor. Check all electrical codes that apply to the application.

18

TABLE 7 – CONTROL OPERATION

HIGHER

LOWER

TORQUE

SETTING

SETTING

100

90

80

TORQUE

70

60

50

40

20

30

P

E

R

C

E

N

T

O

F

B

A

S

E

S

P

E

E

D

100

90

80

70

50

60

PERCENT OF TORQUE

40

30

20

10

10

0

0

FIGURE 29 – LINEAR TORQUE MODE

SETTING

TORQUE

LOWER

SETTING

TORQUE

HIGHER

PERCENT OF TORQUE

100

90

80

70

50

60

40

30

20

10

P

E

R

C

E

N

T

O

F

B

A

S

E

S

P

E

E

D

100

80

70

90

40

60

50

10

20

30

0

0

FIGURE 30 – NON-LINEAR TORQUE MODE

Quadrant

Type of Operation

Motor Rotation

Direction

Motor Torque

Direction

Load Torque

Direction

I

Motoring

CW

CW

CCW

II

Regeneration

CCW

CW

CCW

III

Motoring

CCW

CCW

CW

IV

Regeneration

CW

CCW

CW