Figure 28 – hi-pot test setup, En j11 en j11 – KB Electronics KBRC-240D User Manual

Page 17

K. Enable Jumper (J11) – Jumper J11 is fac-

tory installed to enable the control. If

installing the Enable Circuit, as described

in Section IIJ, on page 13, remove Jumper

J11. See Figure 27.

IV. MOUNTING INSTRUCTIONS

Warning! The KBRC-240D is not designed to be used in an explosion-proof appli-

cation.

It is recommended that the control be mounted vertically on a flat surface with adequate ven-

tilation. Leave enough room below the control to allow for AC line, motor connections and

any other wiring. Although the control is designed for outdoor and wash down use, care

should be taken to avoid extreme hazardous locations where physical damage can occur. If

the control is mounted in a closed, unventilated location, allow enough room for proper heat

dissipation. If operating the control at full rating, a minimum enclosure size of 12”W X 24”H

X 12”D is required. See Figure 3, on page 8.

V.

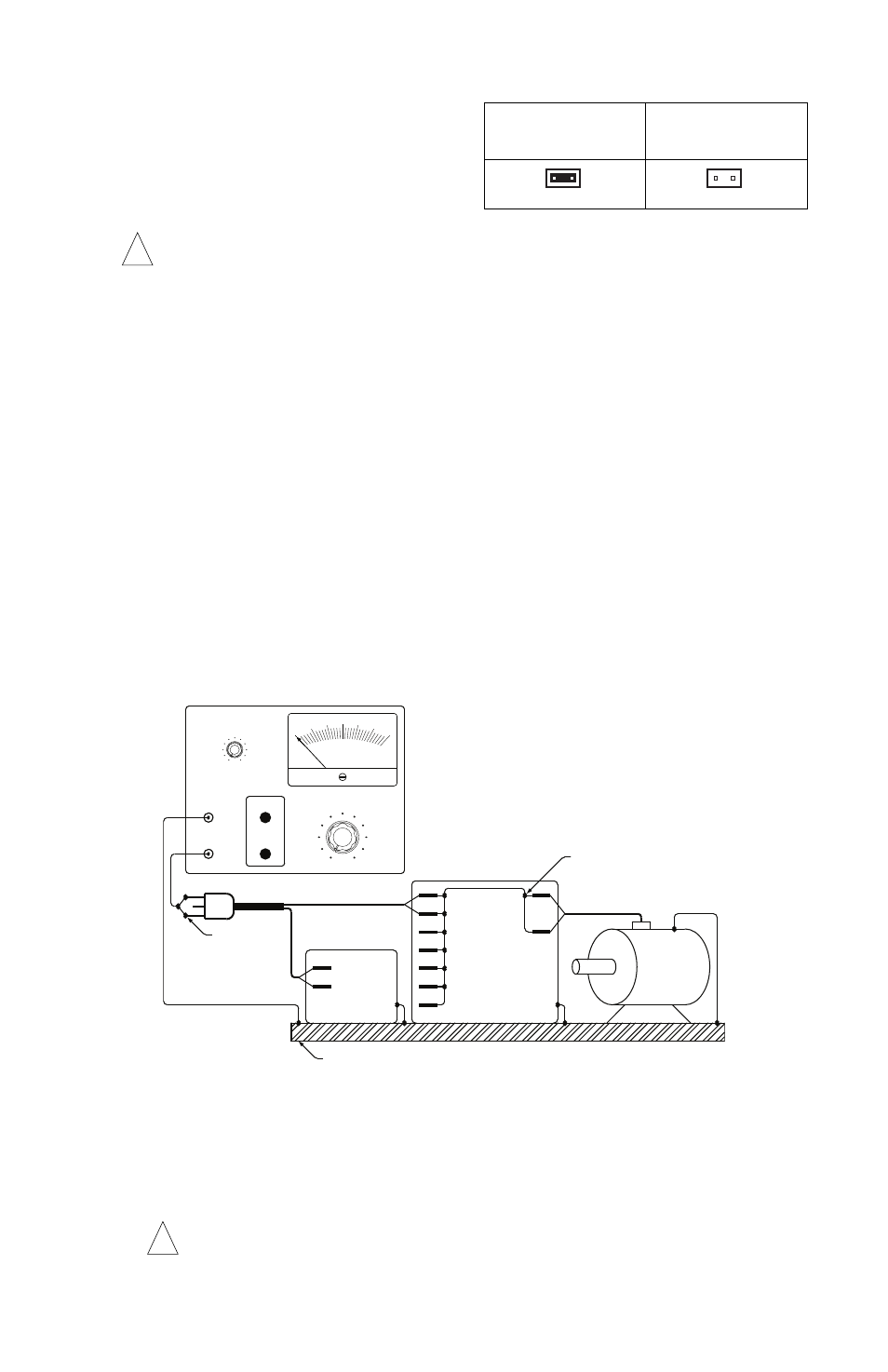

RECOMMENDED HIGH VOLTAGE DIELECTRIC WITHSTAND TESTING (Hi-Pot Testing)

Testing agencies such as UL, CSA, VDE, etc., usually require that equipment undergo a hi-

pot test. In order to prevent catastrophic damage to the speed control, which has been

installed in the equipment, it is recommended that the following procedure be followed.

Figure 28 shows a typical hi-pot test setup.

Note: All equipment AC line inputs must be disconnected from the AC power.

A. Connect all equipment AC power input lines together and connect them to the H. V. lead

of the hi-pot tester. Connect the RETURN lead of the hi-pot tester to the frame on which

the control and other auxiliary equipment are mounted.

B. The hi-pot tester must have an automatic ramp-up to the test voltage and an automatic

ramp-down to zero voltage.

Note: If the hi-pot tester does not have automatic ramping, then the hi-pot output must

be manually increased to the test voltage and then manually reduced to zero. This pro-

cedure must be followed for each machine tested. A suggested hi-pot tester is Slaughter

Model 2550.

WARNING! Instantaneously applying the hi-pot voltage will cause

irreversible damage to the speed control.

17

FIGURE 27 – ENABLE JUMPER

!

!

2

1

3

0

AC KILOVOLTS

RETURN

H. V.

(MAIN POWER DISCONNECTED)

TERMINALS TOGETHER

CONNECT ALL SPEED CONTROL

HIGH VOLTAGE DIELECTRIC WITHSTAND TESTER

MOTOR SPEED CONTROL

(HI-POT TESTER)

SIG

SIGNAL INPUTS

TERMINALS

L1

L2

FRAME

CHASSIS

CHASSIS

MOTOR

MOTOR WIRES

AC LINE INPUTS

RESET

TEST

TO BOTH

CONNECT HI-POT

AC LINE INPUT

LEAKAGE

0mA

10mA

MAX

ZERO

VOLTAGE

AUXILIARY EQUIPMENT

MACHINE OR EQUIPMENT FRAME

L1

L2

-15V

+15V

COM

FIGURE 28 – HI-POT TEST SETUP

J11 Installed for

Auto-Enable

(Factory Setting)

J11 Not installed for

Manual Enable

EN

J11

EN

J11