KB Electronics KBPW-240D User Manual

Page 9

III.

WIRING INSTRUCTIONS

Warning! Read Safety Warning,

on page 1, before using this

control. Disconnect the AC line before

wiring.

Note: To avoid erratic operation, do not

bundle AC line and motor wires with wires

from signal following, start/stop switch,

inhibit, or any other signal wires. Use

shielded cables on all signal wiring over

12” (30cm). Shield should be Earth

grounded on the control side only. Wire

the control in accordance with the National

Electrical Code requirements and other

codes that may apply to your area. See

Figure 3, Table 3 and Table 4, on page 7.

Be sure to properly fuse each conductor that is not at ground potential. Do not fuse neutral

or grounded conductors. See Section VII, on page 12. A separate AC line switch or con-

tactor must be wired as a disconnect so that each ungrounded conductor is opened. An

accessory On/Off AC Line Switch (P/N 9341) may be used in lieu of, or in addition to, the

Start/Stop switch. The switch can be wired for single pole or double pole operation, as

required.

To maintain the watertight integrity of the control, be sure to use suitable watertight connec-

tors and wiring which are appropriate for the application. Two 7/8” (22.2mm) knockout holes

are provided for standard 1/2” knockout connectors (not supplied) for wiring. A watertight

plug is provided if only one knockout is required.

Warning! Do not wire switches or relays in series with the armature. Armature switch-

ing can cause catastrophic failure of motor and/or control. To avoid erratic operation,

do not bundle AC line and motor wires with potentiometer wires, voltage following wires,

Start/Stop switch wires, inhibit wires, or any other signal wires. Use shielded cables on all

signal wiring over 12” (30cm) long. Shield should be Earth grounded on the control side only.

Warning! Do not use CON2 for any purpose other than to power the optional Anti-Plug

Reversing Module APRM-PC (P/N 9378A).

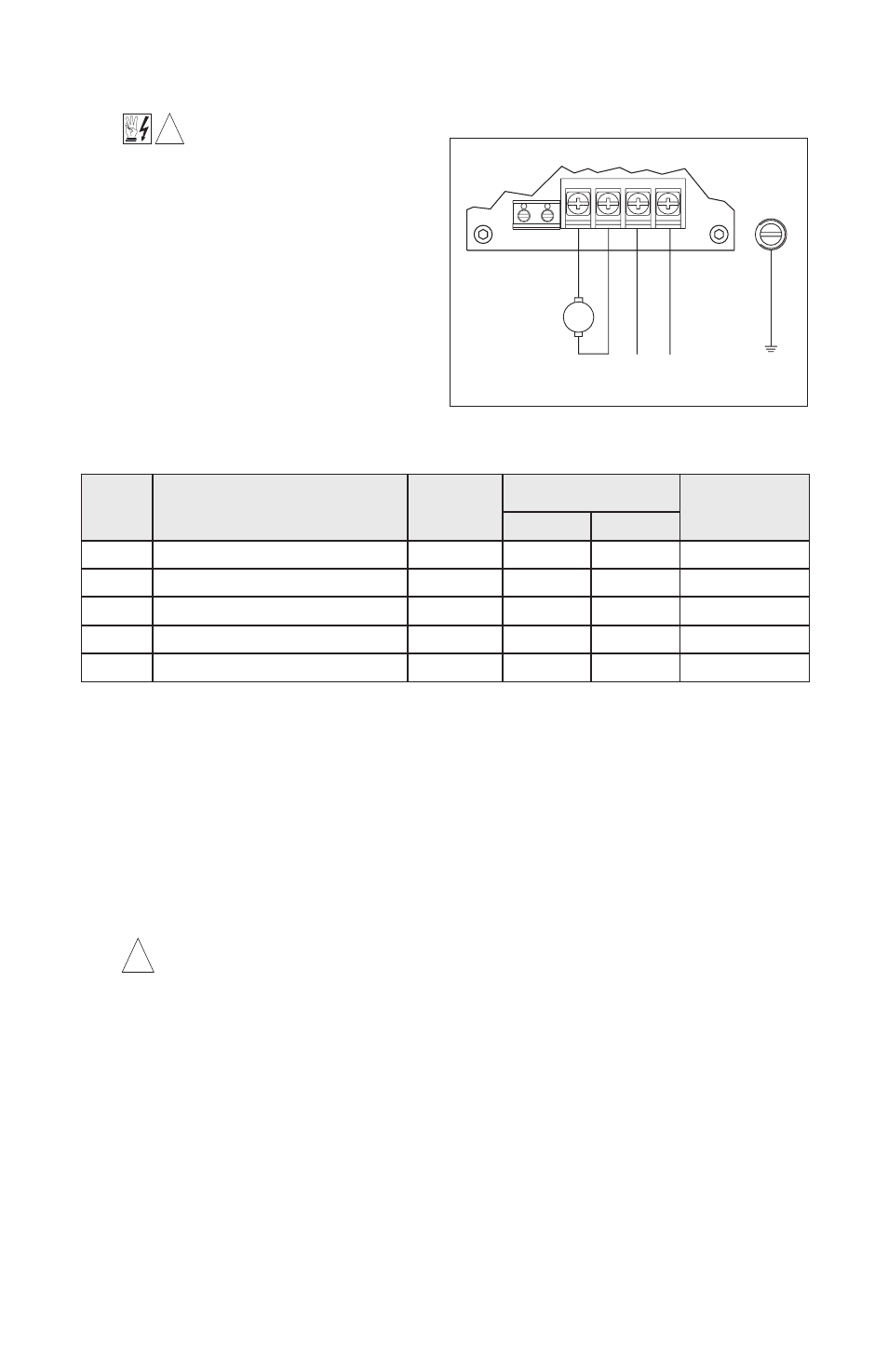

A. AC Line Connection – Wire AC line input to L1 and L2 terminals of TB1 as shown in

Figure 3.

B. Ground Connection – Earth ground the control chassis using the green ground screw

that is provided on the inside of the control to the right side of TB1 as shown in Figure 3.

C. Permanent Magnet (PM) Motor Connection – Wire the motor armature leads to A1 (+)

and A2 (-) terminals of TB1 as shown in Figure 3. Be sure jumper J1 is set to the appro-

priate motor voltage and that J3 is set to the appropriate motor current. For step-down

6

!

!

AC LINE

+

M

-

MOTOR

GROUND

(EARTH)

L2

A2

A1

L1

TB1

TB2

F2

F1

FIGURE 3 – POWER CONNECTION

3.5

12

Terminal

Block

TB1

TB1

TB2

TB3

Supply Wire Gauge

(AWG - Cu)

TB4

Designation

Connections

Maximum

Tightening Torque

(in-lbs)

L1 & L2

A1 & A2

F1 & F2

T+ & T-

K1 & K2

Minimum

Maximum

22

22

24

24

24

12

12

14

14

14

12

3.5

3.5

AC Line Input

Motor Armature

Motor Field (Shunt Wound Motors Only)

Tach-Generator

Run Relay

TABLE 3 – TERMINAL BLOCK WIRING INFORMATION