KB Electronics KBPW-240D User Manual

Page 12

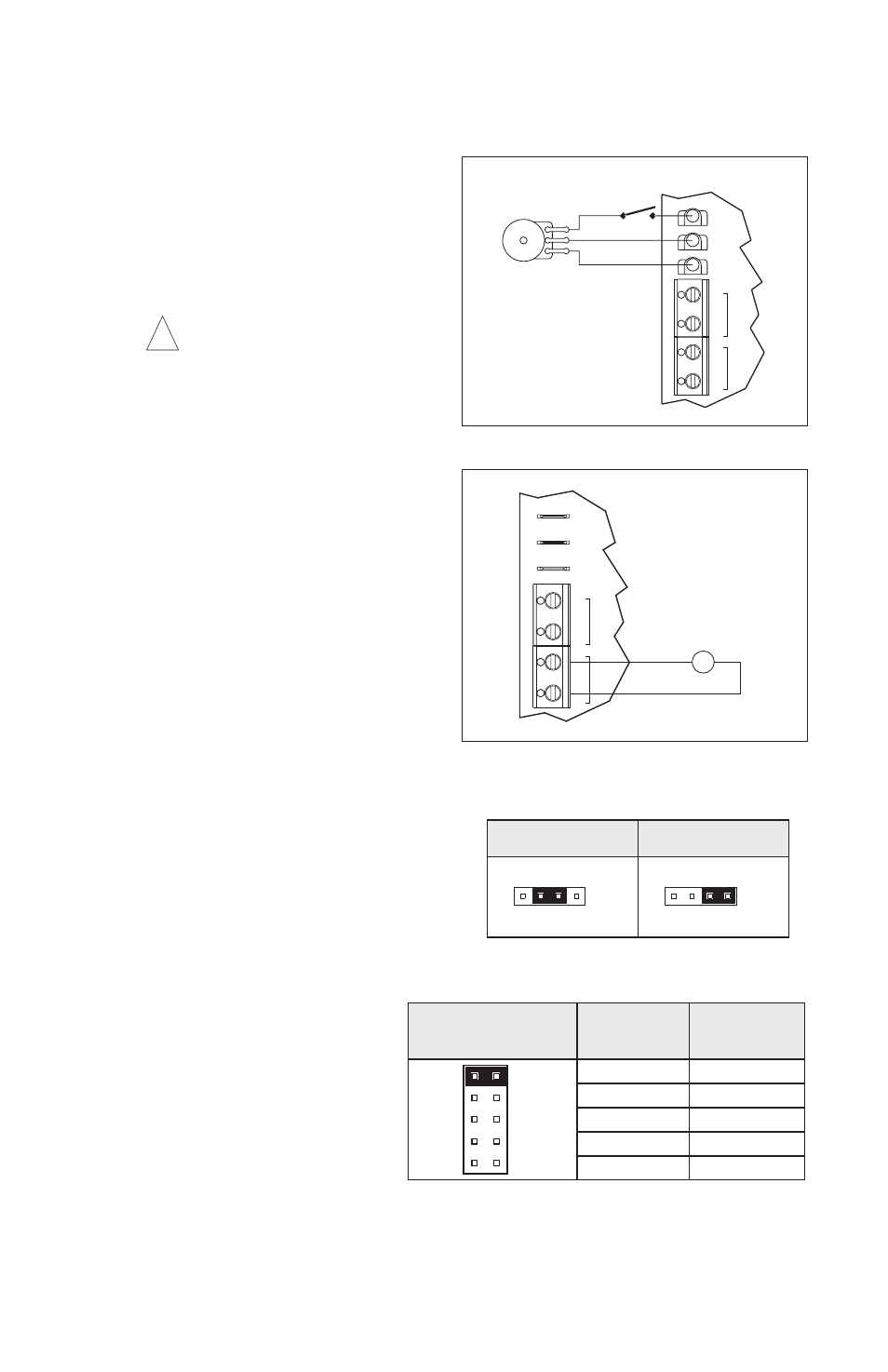

K. Enable Connections – The control can also be started and stopped with an Enable cir-

cuit (close to start). See Figure 10. This circuit functions opposite to that of the Inhibit cir-

cuit (open to start). The Enable function

is established by wiring a switch in series

with the violet main speed potentiometer

lead which connects to the P3 terminal.

When the Enable switch is closed, the

control will accelerate to the main speed

potentiometer setting. When the Enable

switch is opened, the control will coast to

stop.

Warning! Do not use Enable as

a safety disconnect. Use only

the AC line for this purpose. P3 ter-

minal is not isolated and is not to be

Earth grounded.

L. DC Tach-Generator Connection – Wire

the tach-generator to T+ (+) and T- (-)

terminals of TB4 as shown in Figure 11.

Jumper J1 must be in “T” position.

Jumper J4 must be in “7V” position for 7

Volt per 1000 RPM tach-generators or

“50V” position for 50 Volt per 1000 RPM

tach-generators. See section IVD on

page 11.

Note: When using a tach-generator, the

IR trimpot should be set fully counter-

clockwise.

IV.

SETTING SELECTABLE JUMPERS

The KBPW-240D has customer selectable

jumpers which must be set before the con-

trol can be used. See Figure 1, on page 4

for location of jumpers.

A. Motor Voltage Selection (J1) – Jumper

J1 is factory set to “90V” position for 90

Volt SCR rated motors (or 130 Volt

PWM rated motors). For 180 Volt SCR

rated motors (or 220 Volt PWM rated

motors), set jumper J1 to “180V” posi-

tion. See Figure 12.

Note: If jumper J1 is set to “T”

position, a tach-generator must

be wired to TB3. If a tach-gen-

erator is not used, jumper J1

must be in either “90V” or “180V”

position. If jumper J1 is in “T”

position and a tach-generator is

not used, the motor will acceler-

ate to full speed and the main

speed potentiometer will not

control speed.

B. Motor Current Selection (J2) –

Jumper J2 is factory set to “7.5A”

position for 7.5 Amp motors.

*Note: For low (L) motor current range settings (0.8A, 0.5A, 0.4A,

0.3A and 0.2A), it is necessary to remove resistor R35 by cutting it

out of the circuit as shown in figure 14 on page 10.

9

(CLOSE TO START)

SWITCH OR RELAY

Orange

White

Violet

Potentiometer

Main Speed

TACH

P3

P2

P1

TB4

K2

K1

TB3

T-

RELAY

T+

FIGURE 10 – ENABLE CIRCUIT

!

G

DC TACH-GENERATOR

+

-

P3

P1

P2

K2

T-

TB3

RELAY

K1

TB4

T+

TACH

FIGURE 11 – DC TACH-GENERATOR

90V

180V

T

J1

90V

J1

180V

T

J1 Set for 90 Volt Motors

(Factory Setting)

J1 Set for 180 Volt Motors

FIGURE 12 – MOTOR VOLTAGE SELECTION

0.2

7.5

5.0

3.5

2.5

1.7

0.8

0.5

0.4

0.3

Low Scale

Current Range*

(Amps DC)

High Scale

Current Range

(Amps DC)

J2 Set for 7.5 Amp Motor

(Factory Setting)

FIGURE 13 – MOTOR CURRENT SELECTION