HTP 850 LPHL User Manual

Page 58

58

LP- 205 REV. 3.28.14

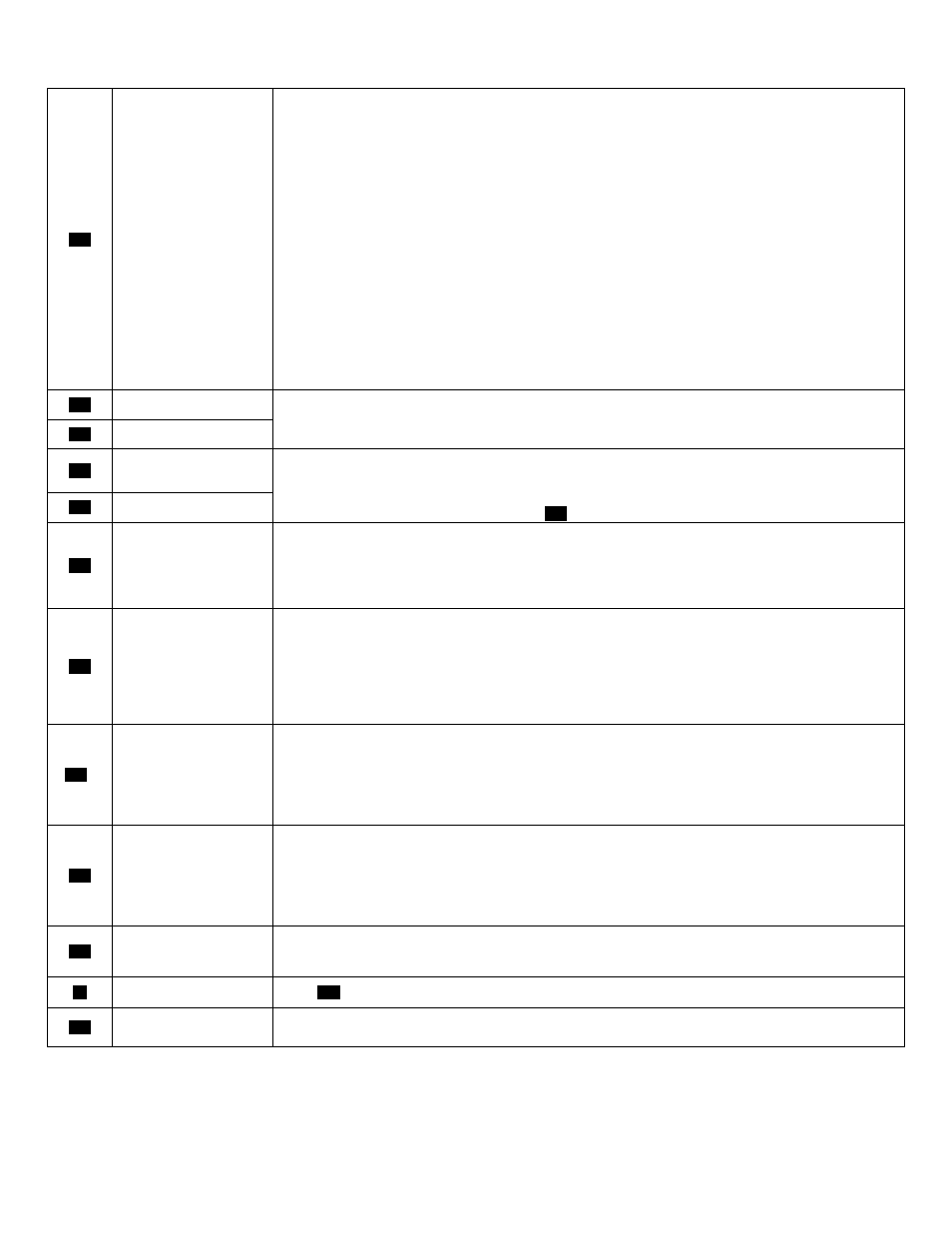

F01

ECO circuit 2

Vent temperature

High Gas Pressure (if

equipped)

Low gas pressure (if

equipped)

Low level (if equipped

with UL353 LWCO)

Thermal Fuse (if

equipped)

1. If the boiler is equipped with High and/or Low gas pressure switches, examine the yellow LED lights on each

switch. If lit, correct the gas supply problem associated with the switch. Then, reset the switch by pressing on

the cover of the switch over the red button. Pressing the button requires a firm push. Finally, press the RESET

button on the front panel of the boiler to reset the boiler control.

2. If the boiler has a UL353 LWCO, check to see if the red LED on the LWCO control box is illuminated. If so,

correct the low water condition and press the reset button on the LWCO control box to reset it. The LED should

change to green. Finally, press the reset button on the front panel of the boiler to reset the boiler control.

3.Check the flue for obstructions or any sign of damage, especially signs of excessive heat. Repair as

necessary. Push red reset button on flue temperature switch located on the flue inside the rear access door of

the boiler.

NOTE: Switch temperature must be less than 90

o

F to reset. Run the boiler and check the flue temperature. If

the flue temperature is within specs and the switch trips, replace the switch. If the flue temperature is excessive,

check and adjust the combustion controls on the boiler. If problem persists, inspect the target wall in the

combustion chamber and replace it if cracked or damaged.

4. If the boiler is equipped with a Thermal Fuse, ensure all wiring to and from the thermal fuse is secure and

intact. Next, check for continuity across the thermal fuse with an ohmmeter. If the ohmmeter registers as open,

the thermal fuse needs to be replaced.

NOTE: Before replacing a thermal fuse, remove the gas valve, blower, and burner assembly and inspect the

heat exchanger and target wall for damage. This is a VERY IMPORTANT procedure, as the heat exchanger

may be damaged and need to be replaced, and should only be performed by a qualified, highly experienced

service technician.

F02

Interrupted or shorted

supply (outlet) thermistor.

1. Check the electrical connection to the appropriate thermistor. Verify 5 VDC by checking in Molex connector.

If not 5 VDC, check harness. If harness is OK, replace control. NOTE: Boiler will reset automatically. Verify

thermistor values by referencing chart in this manual.

2. If connection is okay, replace thermistor.

F03

Interrupted or shorted

return (inlet) thermistor.

F05

Supply (outlet)

temperature sensor

exceeds 230

o

F.

1. Check circulation pump operation.

2. Assure there is adequate flow through the boiler by accessing the status menu and assuring that there is less

than a 50

o

F rise from the return thermistor to the supply thermistor.

3. Check direction of flow on boiler circulator (see PIPING DETAILS in this manual).

4. Troubleshoot thermistor by following steps in

F02

.

F06

Return (inlet) temperature

sensor exceeds 230

o

F.

F09

No flame detected

–

Boiler will make three

attempts at ignition before

the control goes into this

lockout condition.

1. Watch the igniter through the observation window provided.

2. If there is no spark, check the spark electrode for the proper ¼” gap.

3. Remove any corrosion from the spark electrode and flame rectifier probe.

4. If there is a spark but no flame, check the gas supply to the boiler.

5. If there is a flame, check the flame sensor.

6. Check any flue blockage or condensate blocks.

F10

Loss of flame signal

–

The heater will relight 4

times before the control

goes into this lockout

condition. Will reset in 1

hour.

1. Monitor the gas pressure to the unit while in operation.

2. Assure that the flame is stable when lit.

3. Check to see if the green light on the display module is out while the heater is running.

4. If the green light doesn’t come on or goes off during operation check the flame signal on the status menu.

5. If the signal reads less than 1 microampere, clean the flame rectifier probe.

6. If the flame rectifier probe continues to read low, replace it.

7. Check the stability of the flame rectification signal. If the signal is unstable, you may need to replace the

burner gasket.

F11F

False flame signal

– The

boiler will lock out if it

senses a flame signal

when there should be

none present.

1. Look into window. If there is flame, turn the gas off to the unit at the service valve and replace gas valve.

2. If the flame signal is present and there is no flame, replace the flame rectification probe.

3. If the flame signal is not present after turning off the gas supply, check the gas valve electrical connection.

4. Remove the gas valve and check for obstruction in the valve seat or replace the gas valve.

5. Turn the gas on at the service valve after corrective action is taken.

6. Check for condensate backup. Condensate backup can damage the refractory wall. If the wall falls against

the rectifier probe, it may conduct the signal to ground, giving a false reading.

F13

Combustion fan speed

incorrect

– The boiler will

lock out if it senses that

the fan speed is less than

70% or greater than

130% of expected rate for

more than 60 seconds.

1. Check the combustion air fan wiring.

2. Check the 24 VAC signal by measuring from any connected safety to ground. A low voltage situation may

cause a “false” error code.

2. Replace the combustion air fan.

3. Replace the control board.

F20

Condensate cup is full

1. Check condensate lines for obstructions.

2. Check float switch in condensate reservoir.

3. Check wiring from condensate reservoir to 926 control and repair as necessary.

pp

Parameters programmed

Press

{S4}

reset for at least 1 second.

F31

Program parameter error

Control must be re-programmed. If programming does not solve problem, control must be replaced.

Table 16