HTP 850 LPHL User Manual

Page 57

57

LP- 205 REV. 3.28.14

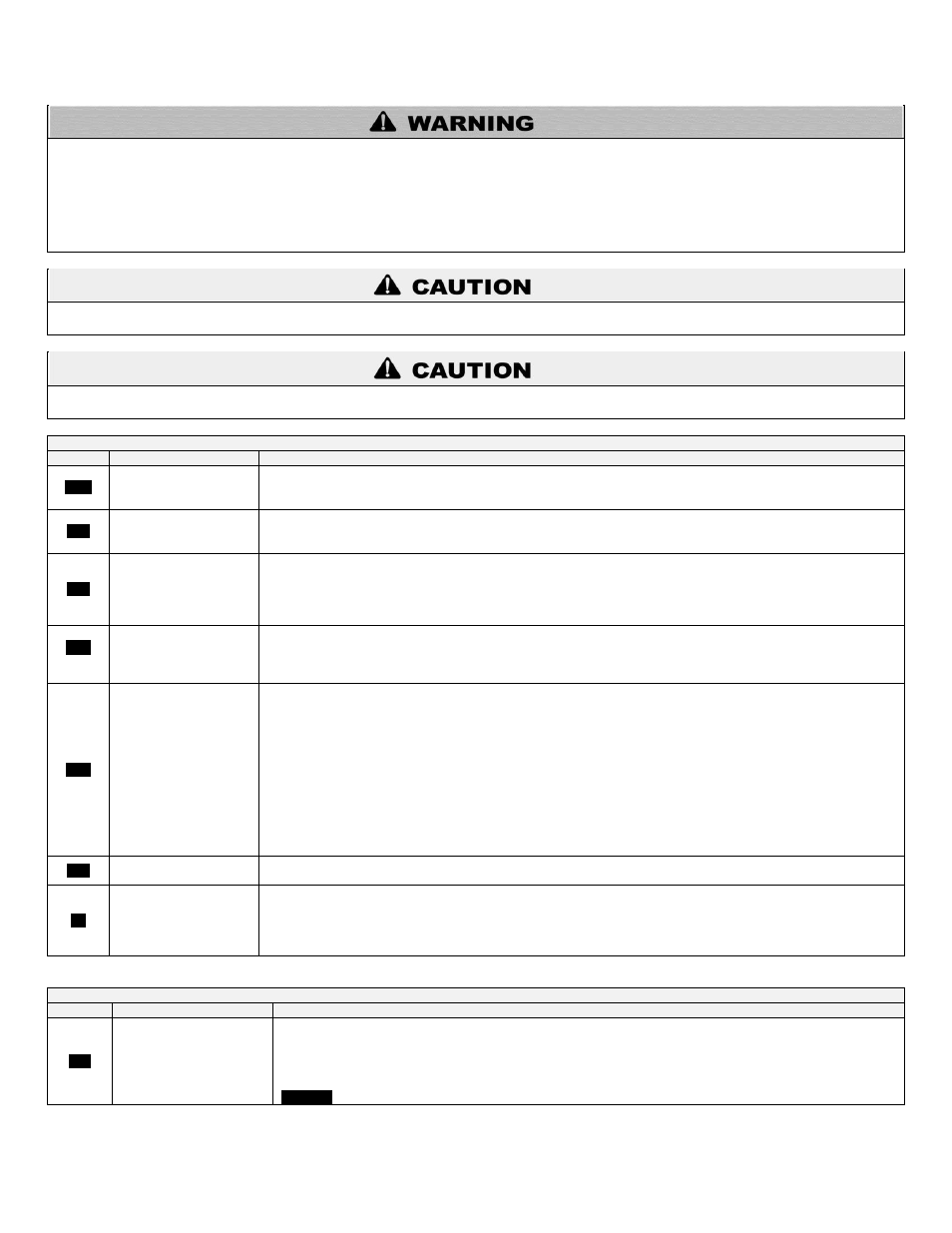

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN SUBMERGED IN WATER. Immediately call a qualified service technician.

The appliance MUST BE replaced if it has been submerged. Attempting to operate an appliance that has been submerged could create

numerous harmful conditions, such as a potential gas leakage causing a fire and/or explosion, or the release of mold, bacteria, or other

harmful particulates into the air. Operating a previously submerged appliance could result in property damage, severe personal injury,

or death.

NOTE: Appliance damage due to flood or submersion is considered an Act of God, and IS NOT covered under product warranty.

This appliance has wire function labels on all internal wiring. Observe the position of each wire before removing it. Wiring errors may

cause improper and dangerous operation. Verify operation after servicing.

If overheating occurs, or the gas supply fails to shut off, do not turn off electrical power to the circulating pump. This may aggravate the

problem and increase the likelihood of boiler damage. Instead, shut off the gas supply to the boiler at the gas service valve.

926 CONTROL BOARD ERROR CODES

CODE

DESCRIPTION

CORRECTIVE ACTION

FOU

Outside sensor shorted

or temperature less

than -40 degrees F.

Inspect wiring from outside sensor for damage or shorted connections. Repair as necessary. Measure resistance

of outdoor sensor and compare to resistance chart. If not within range of chart, shorted or open, replace sensor.

E19

Line voltage frequency

out of range.

Inspect power wiring to appliance and repair as necessary. If connected to line voltage, notify power company. If

connected to an alternate power source, such as a generator or inverter, make sure line voltage frequency

supplied by the device is 60 Hz.

FLU

Blocked Vent Pressure

Switch

1. Check the flue vent to be sure it is not blocked or damaged.

2. Check the switch wiring by applying a jumper in place of the switch. If the code clears with the jumper in place,

REPLACE the flue switch and connect the wires to the new switch BEFORE running the boiler.

WARNING: Do not use jumper to remedy this error. Faulty switches MUST be replaced. Failure to do so could

result in serious injury or death.

LEO

Water Level in Boiler is

Low

1. Check boiler feed water system to be sure it is supplying make-up water to the boiler system.

2. Be sure all air is bled from system.

3. Check for leaks in boiler and system piping and repair as necessary.

4. Inspect low level switch and wiring for damage and repair if necessary.

LOU

24 Volt Low

1. Check line voltage. Must be between 100

– 128 volts.

2. If available, connect a PC and, using HTP service software, check the 24v supply display in the lower left

corner of the screen. The number displayed here must be greater than 128 and should be greater than 250. Use

this as a troubleshooting guide as you follow the steps below.

3. Remove 10 pin Molex connector from customer connection board. If LOU clears, then the problem is with

external sensor wiring. Examine external sensor wiring for shorts to ground, repairing as necessary. If LOU code

is still present and the heater is so equipped, disconnect high gas pressure switch, then low gas pressure switch,

then UL 353 low water cutoff in this order, one at a time, to see if LOU code clears. Replace faulty part. Check low

voltage wire harness in heater for shorts to ground.

4. If LOU only occurs when burner tries to light, check gas valve for excessive current draw.

5. If LOU is present with the low voltage harness disconnected from the 926 control board, replace the 926 control

board.

E03

System sensor failure

(Cascade Master only)

1. Check wiring to system sensor. Repair as necessary.

2. Check sensor resistance. Compare to the resistance table in this manual. Replace if not correct.

FL

Low water flow (Users

with optional flow switch

only).

1. Check to see if boiler circulator is functioning. Repair as necessary.

2. Be sure water is flowing in the system. Check for valves that should be open, plugged filter screens, etc.

3. Check flow switch and wiring. Repair as necessary.

Table 15

926 Control Board FAULT

Codes

Description

Remedy

F00

High temperature limit

exceeded

1. Check circulation pump operation.

2. Assure that there is adequate flow through the boiler by accessing the status menu and assuring that there is

less than a 50

o

F rise from the return thermistor to the supply thermistor.

3. Check thermistor reading on supply thermistor. Replace switch if faulty.

4. Disconnect the two wires from the thermostat terminals and connect the wires together. Depress the

S4/Reset

button. If the fault clears, the problem is outside the boiler.