E. exhaust vent and intake air vent sizing, F. longer vent runs, G. exhaust vent and intake air pipe installation – HTP 850 LPHL User Manual

Page 29

29

LP- 205 REV. 3.28.14

The condensate line must remain unobstructed, allowing free flow of condensate. If condensate freezes in the line, or if line is

obstructed in any other manner, condensate can exit from boiler tee, resulting in potential water damage to property.

E. EXHAUST VENT AND INTAKE AIR VENT SIZING

1. The exhaust vent and intake air vent pipes are 4

” for the Mod Con 300 and 500 and 6” for the Mod Con 850.

2. The total combined equivalent length of exhaust vent and intake air pipe should not exceed 200 feet.

a. The equivalent length of friction loss in elbows, tees, and other fittings are listed in Table 6.

FRICTION LOSS EQUIVALENT FOR STAINLESS OR PLASTIC PIPING AND FITTINGS

FITTING DESCRIPTION

4

”

6

”

8

”

90

o

elbow short radius

3

’

3

’

3’

90

o

elbow long radius

2

’

2

’

2

’

45

o

elbow

1

’

1

’

1

’

Coupling

0’

0’

0’

Tee (intake only)

0’

0’

0’

V Series Vent Kit

1’

1’

1’

AL20 4C Vent Terminal

1’

1’

1’

Pipe (All Materials)

1’

1’

1’

Table 6

– Friction Loss in Equivalent Feet - *Friction loss for long radius elbow is 1’ less.

b. For example: If the exhaust vent has two short 90

o

elbows and 10 feet of PVC pipe we will calculate: Exhaust Vent Pipe

Equivalent Length = (2x3) + 10 = 16 feet.

Further, if the intake air vent pipe has two short 90

o

elbows, one 45

o

elbow, and 10 feet of PVC pipe, the following calculation

applies: Intake Air Equivalent Length = (2x3) + 1 + 10 = 17 feet.

c. The intake air vent pipe and the exhaust vent are intended to penetrate the same wall or roof of the building.

d. The minimum combined equivalent length is 32 combined equivalent feet

– 16 ft intake and 16 ft. exhaust.

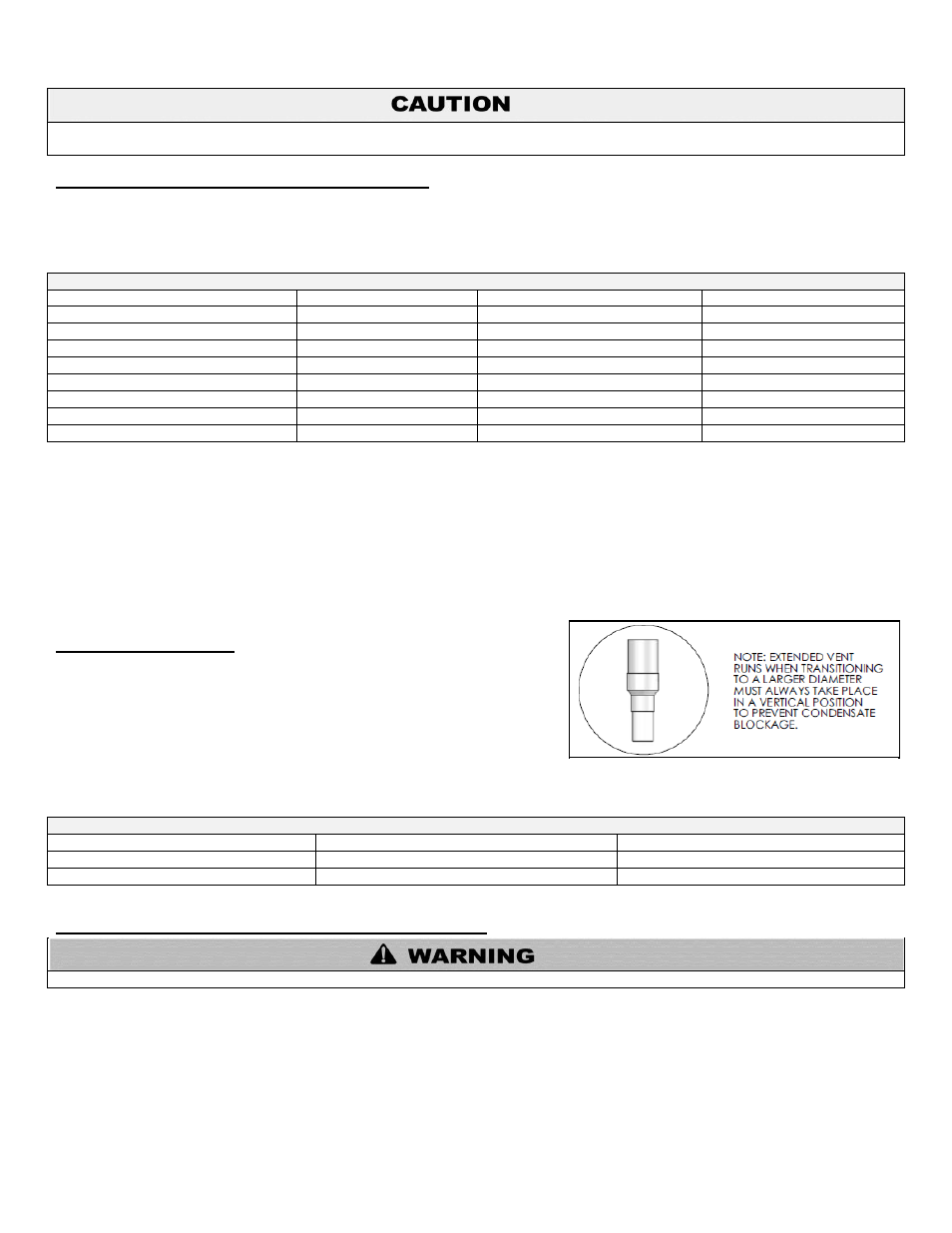

F. LONGER VENT RUNS

The maximum combined equivalent length can be extended by equally

increasing the diameter of both the exhaust and intake air vent pipes. However,

the transitions should begin a minimum of 32 combined equivalent feet from the

boiler equally on both the intake and exhaust.

The maximum equivalent length for increased diameter vent pipes is 275 feet,

which includes the combined 32 feet from the boiler, 16 ft. (inlet) + 16 ft.

(exhaust) = 32 ft. combined with transition total of 245 ft. upsize piping for longer

vent runs.

VENT TRANSITION FITTING

SIZE

REDUCING COUPLING

FINAL VENT SIZE

4” Venting

6” x 4”

6”

6” Venting

8” x 6”

8”

Table 7

– Vent Transition Fitting

G. EXHAUST VENT AND INTAKE AIR PIPE INSTALLATION

All joints of positive pressure vent systems must be sealed completely to prevent leakage of flue products into living space.

1. Use only solid PVC or CPVC pipe, or a Polypropylene vent system, approved for use with Category IV boilers.

FOAM CORE PIPING IS NOT APPROVED FOR EXHAUST APPLICATIONS. Foam core piping may be used on air inlet piping only.

2. Remove all burrs and debris from joints and fittings.

3. When using PVC or CPVC pipe, all joints must be properly cleaned, primed, and cemented. Use only cement and primer approved

for use with the pipe material. Cement must conform to ASTM D2564 for PVC and ASTM F493 for CPVC pipe. NOTE: DO NOT

CEMENT POLYPROPYLENE PIPE.

Figure 14