M. boiler piping details – HTP 850 LPHL User Manual

Page 20

20

LP- 205 REV. 3.28.14

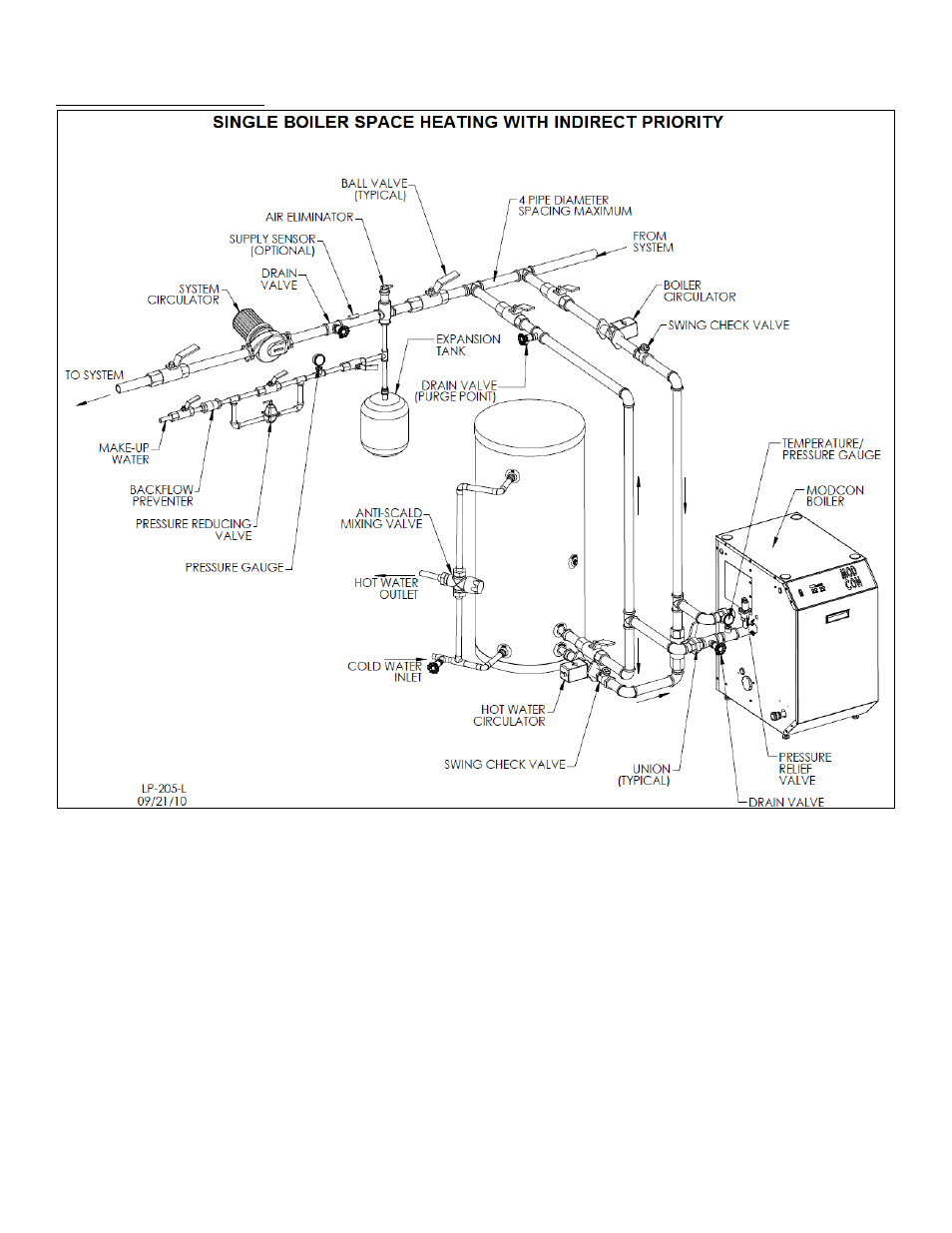

M. BOILER PIPING DETAILS

Figure 8

– Single Boiler Space Heating – Indirect Priority

FIGURE NOTES:

1. This drawing is meant to demonstrate system piping concept only.

2. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119

o

F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. Install a minimum of 6 diameters of straight pipe up and downstream of all closely spaced tees.

5. Piping shown is Primary/Secondary.

6. The minimum pipe size for conn

ecting an HTP indirect fired water heater is 1”.

7. The minimum pipe size for connecting a Mod Con boiler is 1 ½” for the 300 and 2” for the 500 and 850.

8

. System flow (Secondary Loop) must be greater than the boiler’s Primary Loop flow.

9. Installations must comply with all local codes.

10. In Massachusetts, a vacuum relief valve must be installed on the cold water line per 248 CMR.