C. gas table, D. check inlet gas pressure – HTP 850 LPHL User Manual

Page 36

36

LP- 205 REV. 3.28.14

Never use an open flame (match or lighter) to check for gas leaks. Use a soapy solution to test connection. Failure to use a soapy

solution test or check gas connection for leaks could result in substantial property damage, severe personal injury, or death.

Use a two-wrench method when tightening gas piping near the boiler and its piping connection: One wrench to prevent the boiler gas

line connection from turning; the second to tighten the adjacent piping. Failure to support the boiler gas piping connection could

damage the boiler beyond repair. Such damage IS NOT covered by warranty.

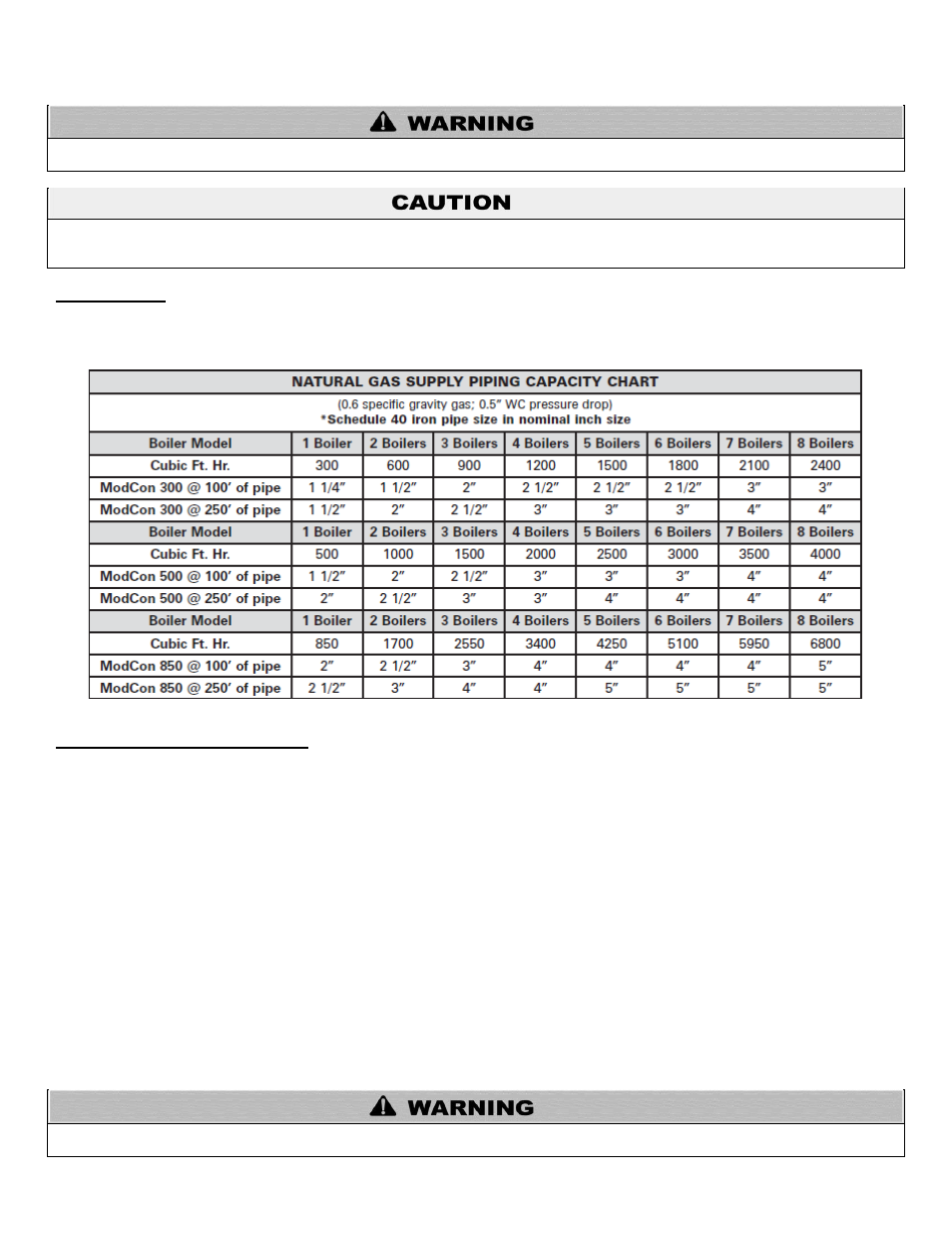

C. GAS TABLE

Refer to Table 8 to size the supply piping to minimize pressure drop between the meter or regulator and unit.

Maximum capacity of pipe in cubic feet of gas per hour for gas pressures of .5 w.c. or less and a pressure drop of .3 inch w.c.

Table 8

– Gas Supply Piping Size Chart for Mod Con Boilers

D. CHECK INLET GAS PRESSURE

The gas valve is equipped with an inlet gas pressure tap that can be used to measure the gas pressure to the unit. To check gas

pressure, perform the steps listed below:

1. IMPORTANT! Before you connect to the inlet pressure, shut off the gas and electrical power to unit.

2. Loosen the pressure tap with a small screwdriver. Refer to Figs. 20 and 21 for locations.

3. Each unit is equipped with a needle valve that will accept a 5/16 ID hose to connect to a digital manometer or liquid gauge to

measure incoming pressure from 0-

35” w.c.

4. Turn on the gas and power up the unit.

5. Put the unit into manual service mode (details on service mode are in the back of this manual). In service mode, monitor pressure to

assure it does not drop below 1 inch from its idle reading. If gas pressure is out of range, or pressure drop is excessive, contact the gas

utility, gas supplier, qualified installer, or service agency to determine the correct action needed to provide proper gas pressure to the

unit. If gas pressure is within normal range, proceed to Step 6.

6. Exit Service mode, then turn power off and shut off the gas supply at the manual gas valve before disconnecting the hose from the

gas monitoring device. Tighten the screw on the pressure tap, turn gas on, and check for leaks with a soapy solution. If a leak is

present, bubbles will appear on the pipe.

Ensure the pressure tap screw is properly tightened to prevent gas leaks. Failure to do so could cause substantial property damage,

severe personal injury, or death.