C. operating instructions, D. programming heater settings – HTP EL-399NVWH User Manual

Page 57

57

LP- 346 REV. 3.20.14

The ENTER key is also used to enable a function for editing. After the user navigates to the desired function, the user would hold down

the ENTER key for one second. When the ENTER key is released, the function value will begin to blink. The function can now be

changed using the

▼▲ ARROW keys. After the new value is displayed, the user then presses the ENTER key for 1 second to lock the

new value of the function in. The value will then stop blinking.

LEFT AND RIGHT ARROW KEYS

– are used to navigate between the default display, status display, analog and cascade dis-

plays if they are enabled. The keys are also used in programming modes to change between the programmable functions. It is

recommended you use the Menu Maps in the back of this manual and the detailed menu instructions printed in this section to help in

menu navigation.

UP AND DOWN ARROW KEYS

– ▼▲ are used to navigate between the various functions displayed in the menu. After the function is

enabled for editing by pushing the ENTER key, the

▼▲ keys are used to adjust the function upward or downward to the desired value.

C. OPERATING INSTRUCTIONS

Before operating the unit, it is important to remove the cover and verify that the gas line and water lines are connected to heater and

fully purged. If you smell gas, STOP; Follow the safety instructions listed in the first part of this section. If you do not smell gas, follow

the next steps.

1. Turn down the thermostats before applying power to the heater. If 0

–10 volt or other inputs are used, make sure that they are set so

there is no call for heat while programming.

2. Turn on the power to the heater or heaters if a cascade system used.

3. Next, check the heater settings. Adjustment and factory defaults are outlined within this section. If a cascade system is used, it is

important that all the heaters have the same heater settings.

4. Next, check the system settings. Adjustments and factory defaults are outlined within this section. If a cascade system is used, it is

important that the Master Heater is programmed with the correct system settings.

5. Create a demand on the heater or heaters if a cascade system is used. The user can monitor system functions when the heaters are

operational.

6. If the heaters fail to start, refer to the troubleshooting section in the back of this manual.

D. PROGRAMMING HEATER SETTINGS

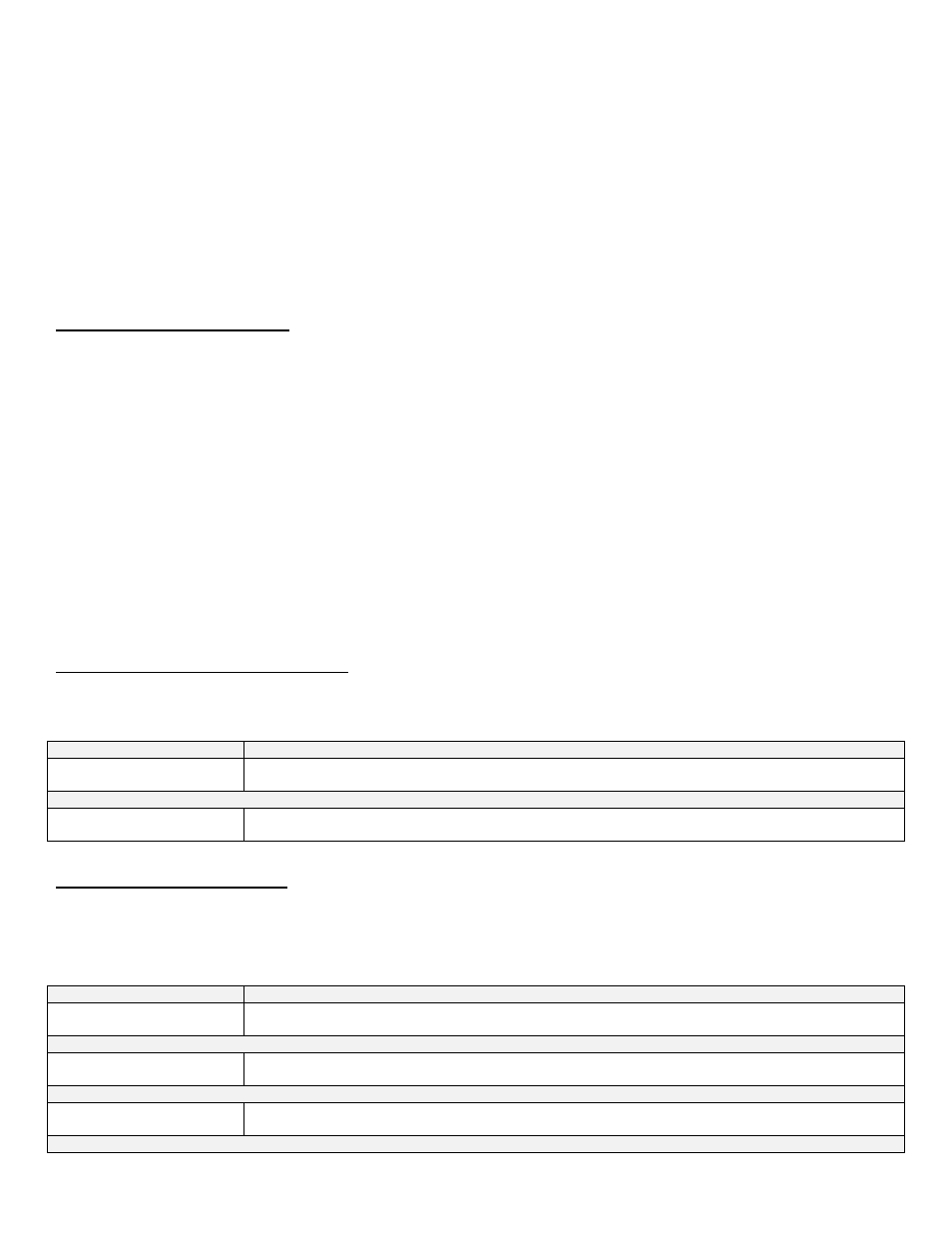

Heater Setting Program Access

Note: Programming the heater control is not possible when the heater is firing. Make sure any input which can create a demand on the

heater, such as the tank thermostat, is turned off, so the heater will remain idle to allow programming.

SCREEN

DESCRIPTION

ENTER MENU CODE

000

To access the heater setting program, press and hold the ENTER Key for 4 seconds, until the display shows the

screen at left.

ENTER MENU CODE

600

Using the arrow keys, log in the Heater

Menu Access Code “600”. To confirm the code, press ENTER to access

Heater Setting Program navigation menu.

Table 17

– Programming Screens

Heater Setting Program Navigation

Once the code is confirmed, the user can now start to set the Heater Settings. Use the arrow keys on the display to navigate through

the Heater Setting Program. A blinking setting indicates it can be changed. To change a setting, press the ENTER Key. Heater

settings can be increased by pressing the UP ARROW

▲ and decreased by pressing the DOWN ARROW ▼ on the display. When

done, press ENTER. Setting will stop blinking and you can move on to next setting. Press RESET to exit programming and store

settings. Listed below are the heater settings that can be programmed into the control.

SCREEN

DESCRIPTION

IGNITION DIFF SET

7

o

F

Function: Allows the user to adjust the ignition differential set point from 1

o

F to 36

o

F (Factory Default 7

o

F). Degrees

below set point must be equal to or below tank differentials.

TANK SETPOINT

120

o

F

Function: Adjusts the tank set point from 59

o

F to 180

o

F (Factory Default 120

o

F).

TANK DIFF SETPOINT

7

o

F

Function: Adjusts the tank differential set point from 1

o

F to 18

o

F (Factory Default 7

o

F). Degrees below set point

where demand starts.