E. circulator pumps, F. installation of the flow switch – HTP EL-399NVWH User Manual

Page 17

17

LP- 346 REV. 3.20.14

Undersized expansion tanks cause system water to be lost from the relief valve, causing make-up water to be added. Eventual heater

failure can result due to excessive make-up water addition. SUCH FAILURE IS NOT COVERED BY WARRANTY.

2. The expansion tank must be located as shown in Part 4, Heater Piping, or following recognized design methods. See expansion tank

manufacturer’s instructions for details.

DO NOT install automatic air vents on closed type expansion tank systems. Air must remain in the system and return to the tank to

provide an air cushion. An automatic air vent would cause air to leave the system, resulting in improper operation of the expansion tank.

E. CIRCULATOR PUMPS

Every VWH system requires special attention to pump size in order to overcome pressure drop through the heater and its related

piping. All circulators installed on the VWH system must be designed for potable water installations. For pressure drop, see Table 6.

Water temperature above 140

o

F requires the circulator to run continuously. Water hardness must be between 5 and 7 grains. Hardness

above 7 grains will damage the heat exchanger and shorten the service life of the heater.

DO NOT use the heater circulator in any location other than the ones shown in this manual. The heater circulator location is selected to

ensure adequate flow through the heater. Failure to comply with this caution could result in unreliable performance and nuisance

shutdowns from insufficient flow.

F. INSTALLATION OF THE FLOW SWITCH

1. Choosing the correct flow paddle:

Your heater comes with a flow switch and four flow paddles. The paddle you use depends on the model of the heater.

ELITE VWH MODEL

PADDLE SIZE

EL-80/110/150/220 VWH

H1

EL-299/301 VWH

H2

EL-399 VWH

H3

N/A

H4

Table 3

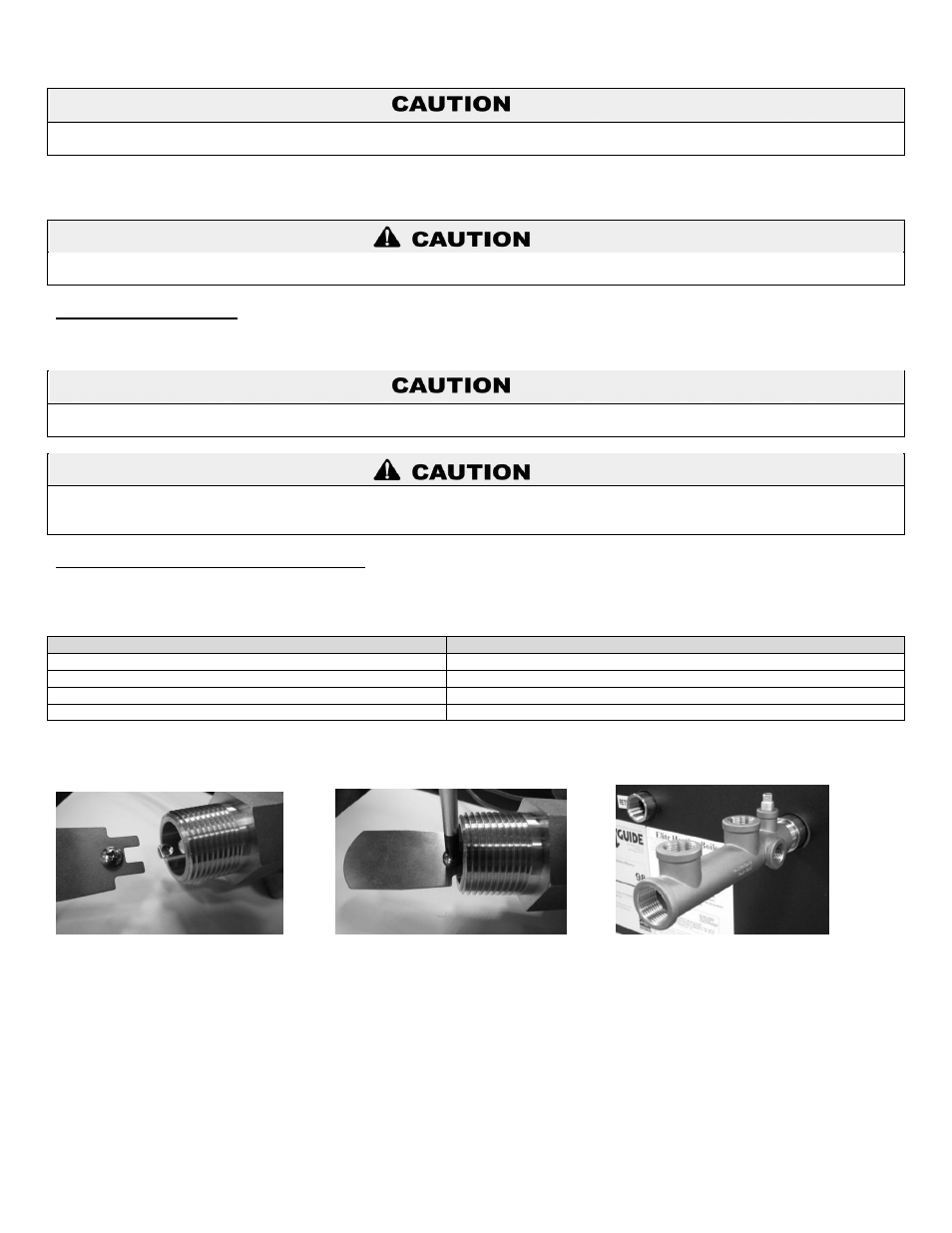

2. Attach flow paddle as shown.

3. Thread outlet combination fitting onto supply outlet of heater using pipe dope.

4. Thread flow switch into outlet combination fitting using pipe dope, making certain the FLOW arrow points in the correct direction.