Harwin Z80-255 User Manual

Page 9

IS-27 Issue: 6 Date: 14.11.11 C/Note: 11542

Page 9 of 9

CARE OF TOOL

Although the Rigidus tool is engineered for durability, it is recommended that the following

maintenance points are observed, to maximise the life of the tool.

1.

Remove dust, moisture, and other

contaminants with a clean brush, or

soft, lint-free cloth.

2.

Do not use any abrasive materials

that could damage the tool.

3.

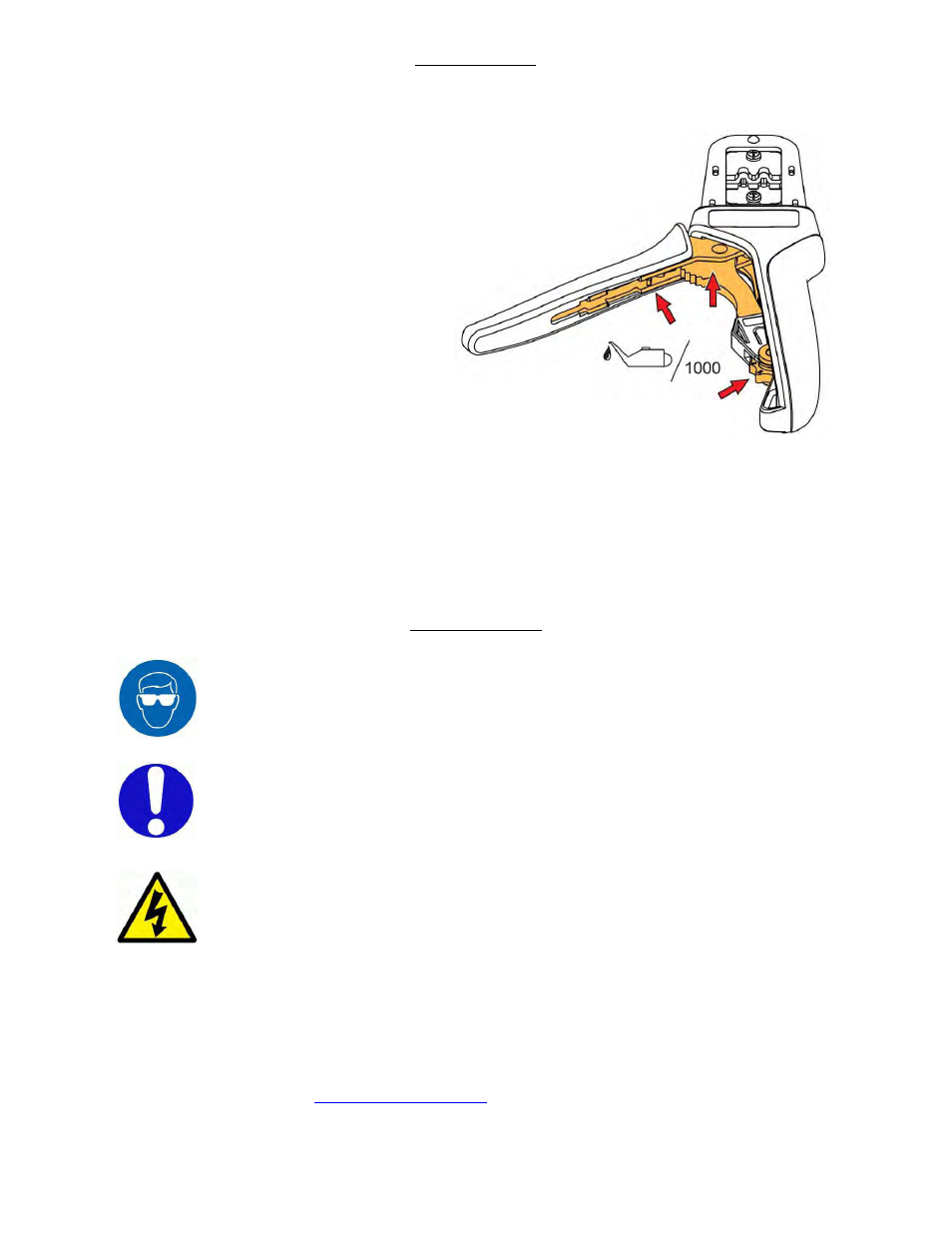

All pins, pivot points and bearing

surfaces should be covered with a

thin coat of high quality machine oil

– do not oil excessively. Light oil

(such as 30 weight automotive oil)

used at the oil points shown in the

diagram, is recommended.

4.

Wipe excess oil from hand tool, particularly from the crimping area. Oil transferred onto

crimp contacts may affect the electrical characteristics of the connector.

5.

When tool is not in use, keep the handles closed to prevent objects from becoming lodged

in the crimping dies, and store the tool in a clean, dry area.

ADVICE ON USE

Wear eye protection at all times.

Manual tools such as this Rigidus tools are intended for low volume use. Repetitive,

high-volume use is not recommended.

The insulated rubber handles are not designed or certified for protection against

electrical shock.

Use with the Trio-Tek crimp contacts listed on the first page of this instruction sheet.

This tool is designed for hand use only, and must not be used with clamping, fixturing or use of

handle extensions.

If you have any questions about this instruction sheet, or the Trio-Tek range of Datamate

connectors, please contact

.