Crimp inspection – Harwin Z80-255 User Manual

Page 4

IS-27 Issue: 6 Date: 14.11.11 C/Note: 11542

Page 4 of 9

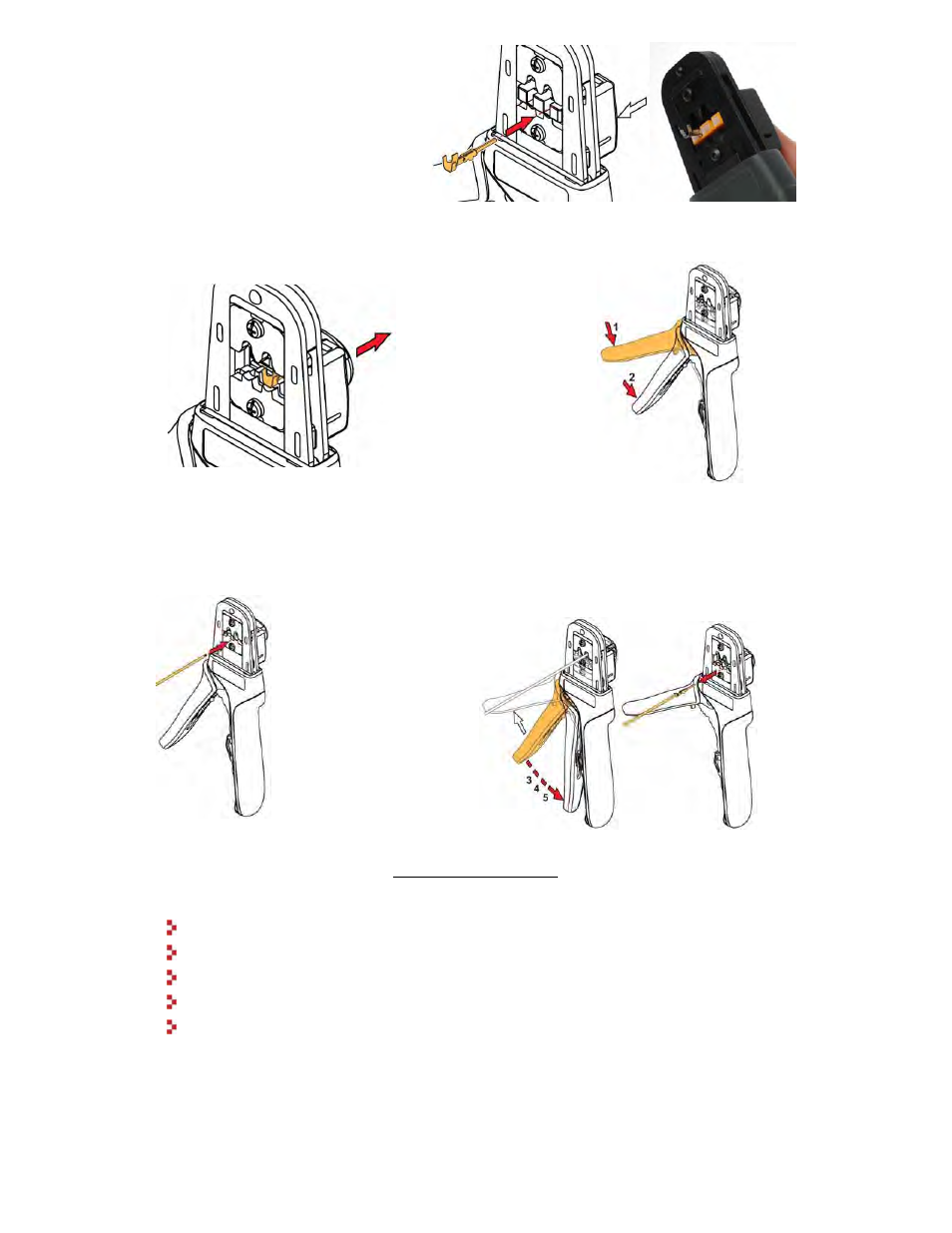

4.

Release the locator button, allowing

the crimp contact to move back

between the crimping jaws.

5.

Close the handle, until the second

ratchet position engages.

6.

Load the stripped wire

through the terminal, and

against the wire stop inside

the tool.

7.

Whilst holding the wire against the wire stop,

complete the crimp by squeezing the tool handles

together through the rest of the ratchet clicks –

another 3, to make 5 in total. The handles should

then be free to open. Remove the crimped wire.

CRIMP INSPECTION

Crimp joints should be checked for:

Correctness of form and location of crimp.

Freedom of fracture and rough edges.

Adequate insertion of all conductor strands in the crimp barrel.

Absence of damage to the conductor or the insulation.

Correct crimp height, as per crimp height values given on front page.

A destructive pull-off force test should also be performed occasionally, to confirm the hand crimp

tool is still operating correctly. The correct values for this test are given on the front page of this

instruction sheet. Insulation should be stripped back beyond insulation crimp area before

preparing samples for pull-off force test.