Wire preparation, Crimping procedure – Harwin Z80-255 User Manual

Page 3

IS-27 Issue: 6 Date: 14.11.11 C/Note: 11542

Page 3 of 9

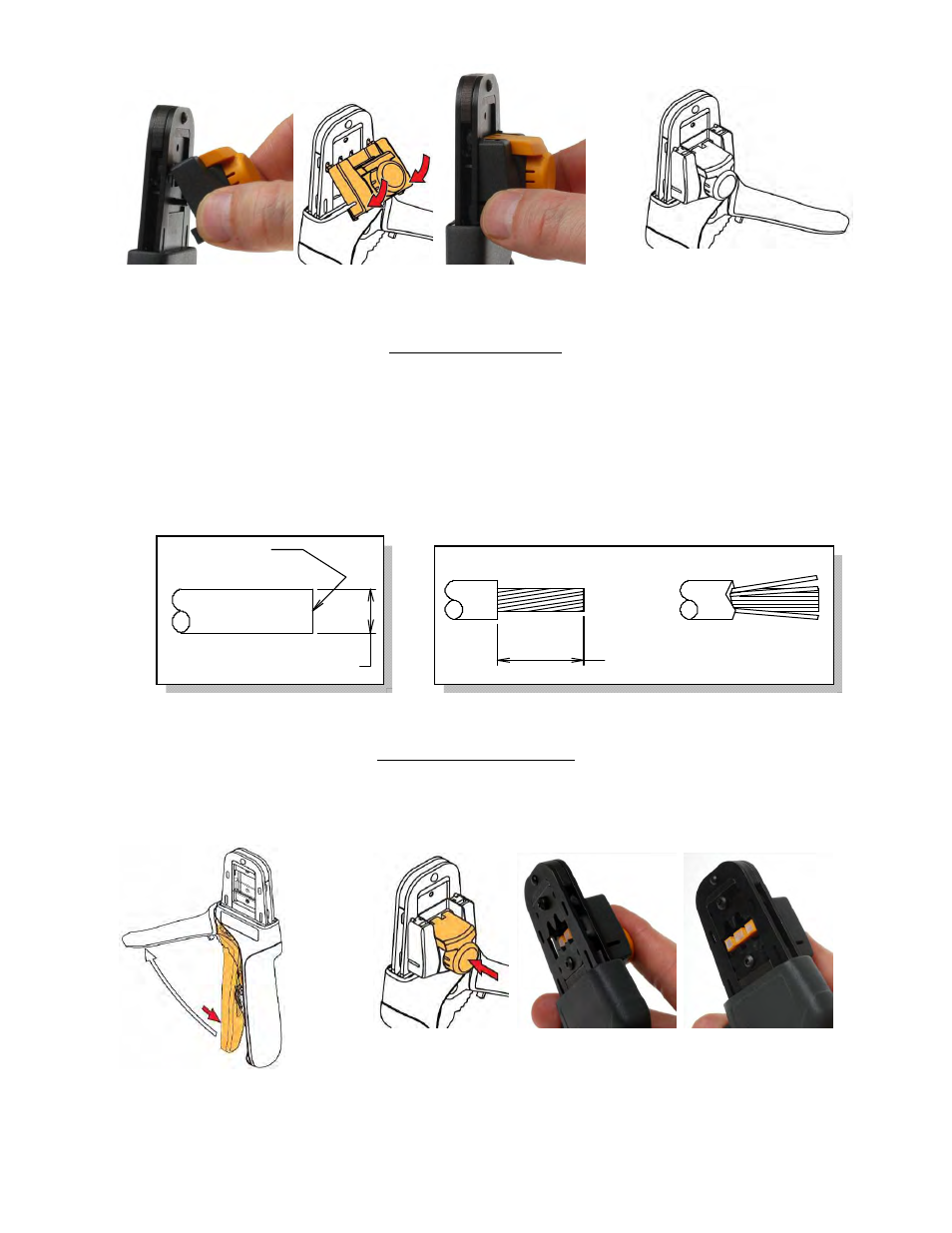

Rotate the locator down, snapping the lower tabs on the locator

into the bottom slots on the tool.

Correct position for the

locator.

WIRE PREPARATION

1.

Ensure that the wire to be crimped is within the specified range of sizes for the contact and

the crimp tool. Failure to use the specified wire size will result in poor quality crimps and

possible tool damage.

2.

Cut the end of the cable to be terminated so that there is a clean cut end (Figure A). Strip

the cable to the correct length (Figure B) using a PTFE Wire stripper, preferably with

adjustable rotating cutter. This should result in all the strands laying together neatly. If the

lay of the strands is disturbed, it may be re-imposed with a slight twist.

Clean cut

Ø1.10mm max

RIGH T

W RONG

2.70 – 3.00m m

Figure A

Figure B

CRIMPING PROCEDURE

1.

Ensure that the crimp

tool is at the fully

open position.

2.

Push the button on the back of the locator, which will

move the locator forward between the crimp dies.

3.

Whilst holding the locator in the forward

position, insert the crimp contact into the correct

locator nest. The wire size is marked on the

crimp die, above each location.