Harrington Hoists and Cranes RH Wire Rope Hoist User Manual

Page 32

32

7)

When installing the trolley hoist on a beam, ALWAYS raise the hoist into position

with the trolley and hoist assembled together and securely attached to a pallet. Raise the trolley and

hoist with a forklift, lifting platform, or other similar means. NEVER use slings to raise and install the

trolley hoist onto the beam (see Figure 3-22).

8) Using a forklift or another suitable means, position the pallet so that the horizontal axis of the beam is

parallel to the horizontal axis of the hoist (see Figure 3-23).

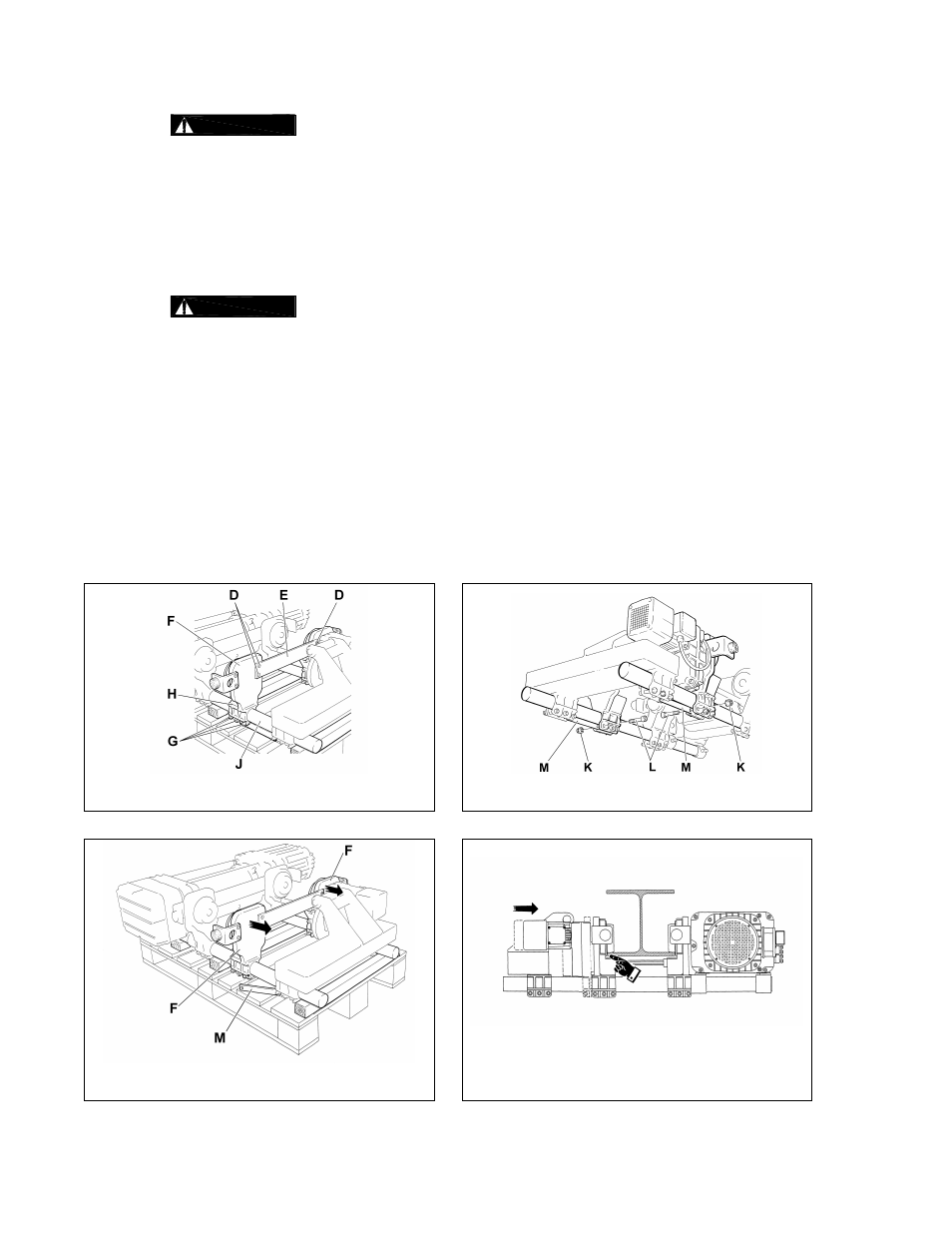

9) Temporarily slide the Side Plates (F) on the counterweight side along the Load Bars (J) so that the

distance between the faces of the trolley wheel is wider than the beam flange (see Figure 3-26).

10)

This applies to ultra-low headroom trolleys only. When preparing the trolley for

placement on the beam, ALWAYS move the Side Plates (F) on the counterweight side, DO NOT

remove the Side Plates (F) on the hoist side. DO NOT remove the counterweight.

11) Use a movable scaffolding or a lifting platform so that one person can reach the height of the beam and

guide the forklift operator. Raise the pallet slowly and carefully avoiding any swinging or oscillations

until the trolley hoist reaches the bottom flange beam.

12) Guiding the fork lift operator, slowly raise the pallet while keeping it level until the running surface of the

trolley wheels are above the bottom flange of the beam. Then move the pallet horizontally until the

trolley wheels on the hoist side are over the bottom flange.

13) From the scaffolding or lifting platform, slide the previously moved Side Plates (F) along the Load Bars

(J) until the trolley wheels are over the beam flange and the trolley wheel flanges of the Side Plates (F)

on the counterweight side are very close to the edge of the beam flange (see Figure 3-27).

Figure 3-24 Loosen Bolts

Figure 3-25 Disconnect Tie Bar

Figure 3-26 Slide Side Plates Out

Figure 3-27 Place Wheels on Beam