Harrington Hoists and Cranes RH Wire Rope Hoist User Manual

Page 31

31

3.4.4

Ultra-Low Headroom Trolley Installation

1) Make sure the mounting location complies with Section 3.3.

2) Install any additional devices, if any (power supply cords or pendants, for instance – see Section 3.5)

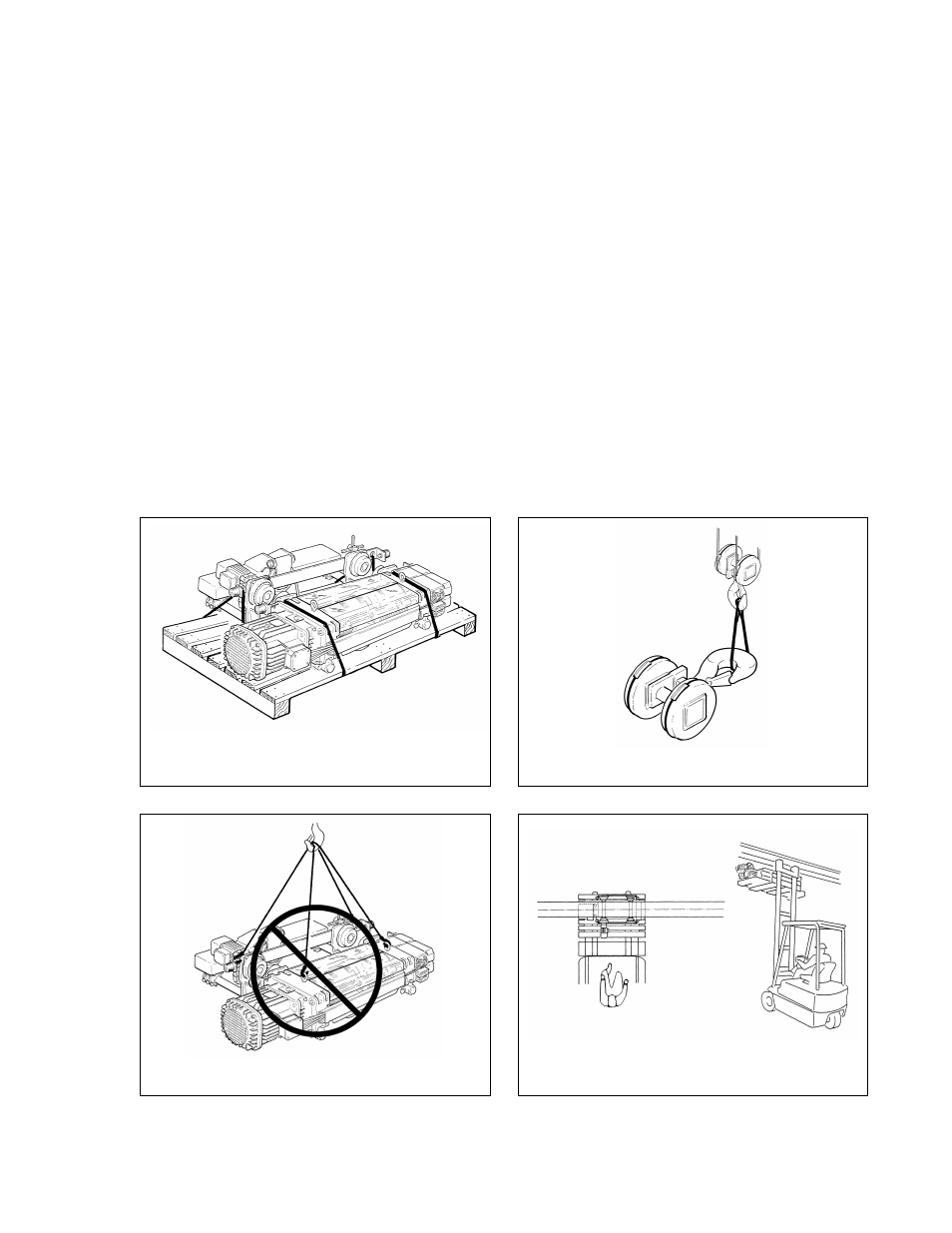

onto the trolley hoist. If the trolley hoist is not secured to a pallet, place and secure it to one making

sure that the trolley hoist is completely stable (see Figure 3-20).

3) Remove the Bottom Block from the pallet/packing and place it on the ground. Use a hoist or other

suitable lifting means to pickup the Bottom Block if it is heavier than 50 pounds (weight is written on the

container if it exceeds 50 pounds). Always lift/hold the Bottom Block from the Hook regardless if it is

lifted using a hoist or handled manually (see Figure 3-21).

4) On the counterweight side, loosen the Screws (D) that attach the Stiffening Plates (E) to Side Plates (F)

and loosen the Lock-Nuts (G) on the Stirrups (H) that secure the Side Plates (F) to the Load Bars (J)

(see Figure 3-24).

5) Remove the Nuts (K) and Socket Bolts (L) to remove the Spacers (M) from the Stirrups (H) so that the

Side Plates (F) on the counterweight side can move freely along the Load Bars (J) (see Figure 3-25).

6) For relatively small beam flange widths (at the lower end of the flange range – see Table 2-8), the

trolley Drive Shaft must be shortened to allow the Side Plates (F) to adjust close enough together as

required. Drive the Spring Pin attaching the Drive Pinion, slide the counterweight side Side Plates (F)

out and remove the Drive Shaft. After cutting the Drive Shaft, reinstall it onto the trolley and reattach

the Drive Pinion.

Figure 3-20 Trolley Secured to Pallet for

Installation

Figure 3-21 Lifting Bottom Block

Figure 3-22 Improper Method for Lifting

Figure 3-23 Positioning the Trolley Hoist