Danger – Harrington Hoists and Cranes RH - Advantage Wire Rope Hoist User Manual

Page 39

39

6.3

Trolley Motor Brake

6.3.1

The Trolley Brake adjustment can be accomplished 2 ways:

+ External Method – External adjustment in the case of moderate wear or when changing the brake

pre-sets.

+ Internal Method – Internal adjustment is required after the External method does not provide

enough braking. This usually occurs when brake wear exceeds 1mm.

6.3.2 To adjust the trolley motor brake for either the external or internal method, it is necessary to

perform the following steps:

1)

DANGER

Before proceeding, ensure that the electrical supply for the hoist or trolley has

been de-energized (disconnected). Lock out and tag out in accordance with ANSI Z244.1

“Personnel Protection –Lockout/Tagout of Energy Sources”.

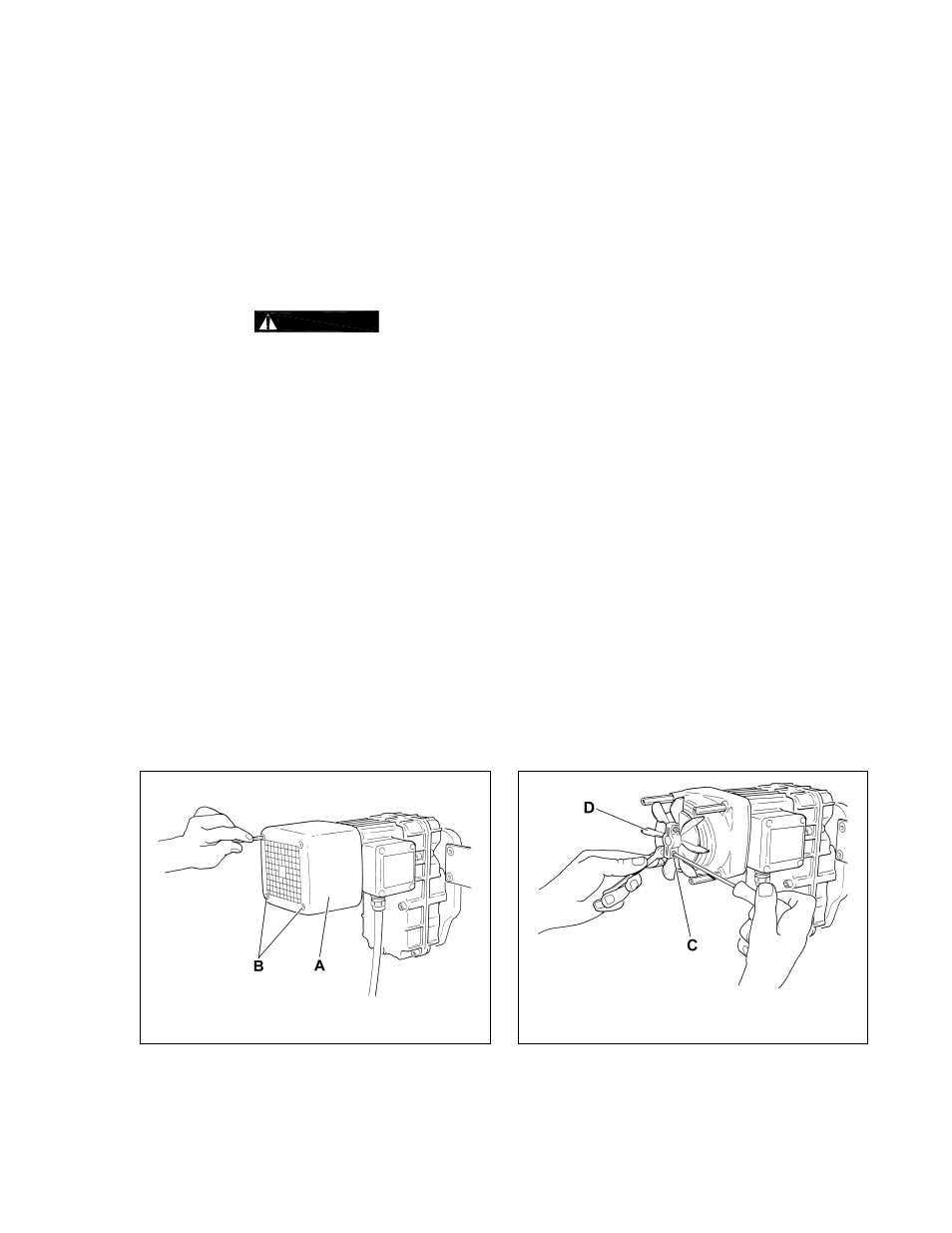

2) Remove the trolley Motor Cover (A) by unscrewing the 4 Screws (B) (see

Figure 6-4

).

6.3.3 External Method – The external method allows the braking force to be increased or decreased as

required without disassembling the brake.

1) Remove the Lock-Nut ®, Fan (D), external Thickness Washers (E), Snap Ring (F), Pressure

Washer (G) and Spring (H) (see

Figure 6-5 and 6-6

).

2) To INCREASE braking, add some or all of the external Thickness Washers (E) to the Thickness

Washers (E) adjacent to the motor as necessary to obtain the required braking force (see

Figure 6-

6

).

3) To DECREASE braking, remove a quantity of the internal Thickness Washers (E) adjacent to the

motor and add them to the external Thickness Washers (E) during re-assembly (between the fan

(D) and the snap ring (F) as required to obtain the required decrease in braking force (see

Figure

6-6

).

4) Reinstall the Spring (H), Pressure Washer (G), Snap Ring (F), Thickness Washers (E), Fan (D)

and Lock-Nut ®.

5) Reinstall the trolley Motor Cover (A) using the 4 Screws (B).

6) Perform brake tests and repeat the above steps as necessary to obtain the required trolley braking.

Figure 6-4

Figure 6-5