Maintenance, Archive, Routine preventive – Ransburg 9040 Classic HV Power Supply 76447 User Manual

Page 24: Troubleshooting

CP-97-02.5

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

ROUTINE PREVENTIVE

ROUTINE PREVENTIVE

ROUTINE PREVENTIVE

ROUTINE PREVENTIVE

ROUTINE PREVENTIVE

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

MAINTENANCE

In general, little maintenance is necessary to

ensure proper operation. However, it is important

to keep the interior of the unit clean and free from

moisture or foreign material. For this reason the

following must be done:

1. Keep the exterior of the unit free from dust

accumulation.

2. Always clean the exterior prior to opening the

cabinet door.

3. Open the cabinet door only to perform

maintenance or repair.

4. If the power supply end of the high voltage

cable becomes dirty, clean the end of the cable

with a suitable, clean, non-polar solvent and apply

a light coat of dielectric grease. On a yearly basis,

check to ensure that the dielectric oil (70863-00) is

covering the electrical contact point in the high

voltage tube. If not, add oil as needed.

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

PC Board T

PC Board T

PC Board T

PC Board T

PC Board Test Jumper

est Jumper

est Jumper

est Jumper

est Jumper

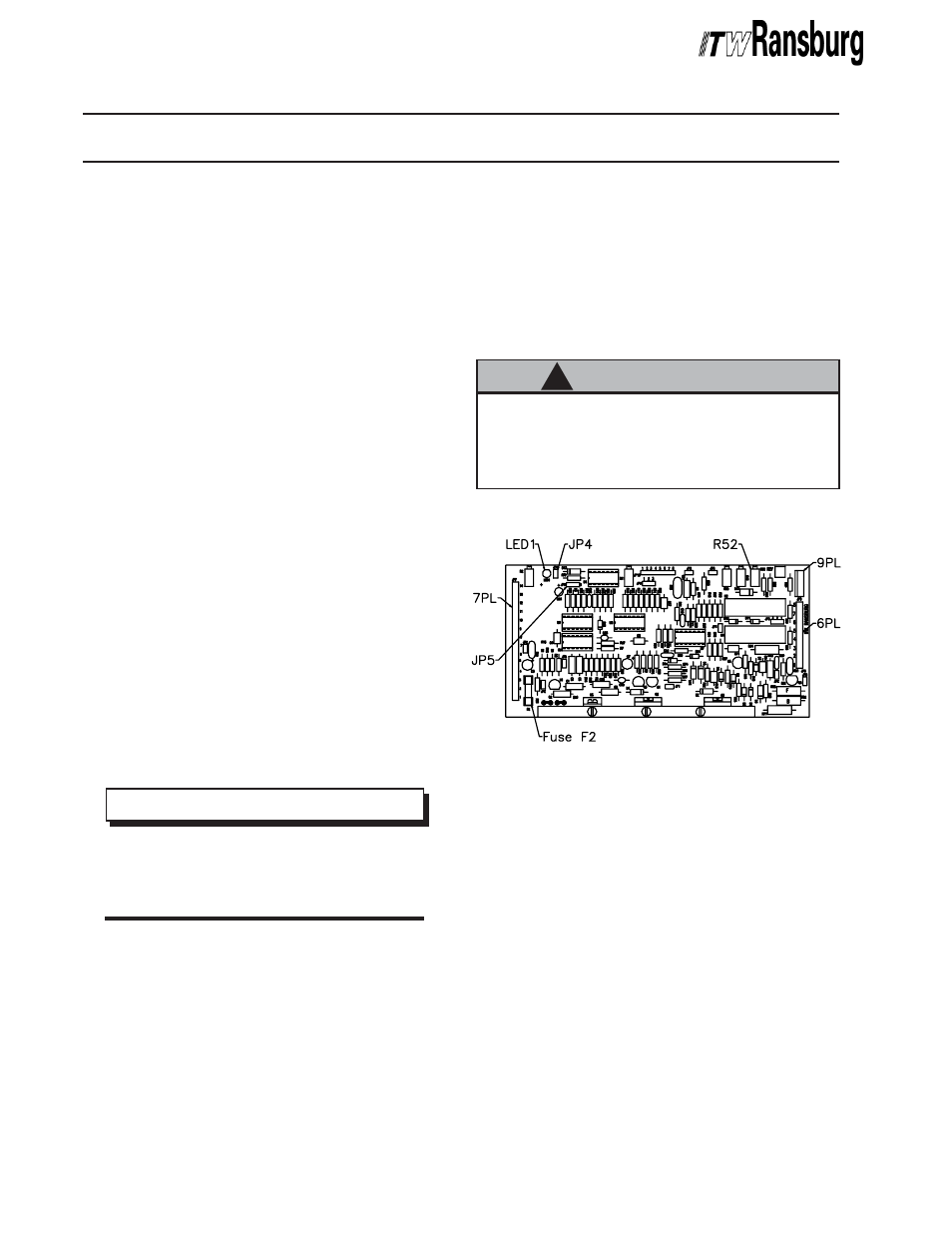

To assist in testing and troubleshooting, a jumper

(JP4) has been incorporated on the 9040 PC

Board. By covering (shorting) both terminals, the

high voltage on relay is triggered. Thus, for testing

and troubleshooting, high voltage output can be

obtained without the need to trigger the spray

applicator or user supplied control device. Just

remember to reposition the jumper after testing, so

that it covers only one terminal or the high voltage

will stay on all the time. (See Figure 7 for location

of test jumper JP4.)

Ground T

Ground T

Ground T

Ground T

Ground Test Procedure

est Procedure

est Procedure

est Procedure

est Procedure

Equipment Required:

Equipment Required:

Equipment Required:

Equipment Required:

Equipment Required:

- Ohmmeter (to measure resistance)

If shocks or sparks are noticed at any point in the

spray system, immediately turn off the power

supply and check the complete system for proper

grounding. Proper grounding of the spray applicator

system can be verified as follows:

1. Ensure that the clamp of the 14 AWG ground

wire assembly is connected to true earth ground.

The resistance between the clamp and a known

earth ground should read less than 25 ohms.

Figure 7: Main PC Board

Figure 7: Main PC Board

Figure 7: Main PC Board

Figure 7: Main PC Board

Figure 7: Main PC Board

>

Squirting 70863-00 dielectric oil down

the HV tube significantly reduces corona

discharge that can cause deterioration of

the HV connection components.

N O T E

N O T E

N O T E

N O T E

N O T E

>

If JP4 is left covering (shorting) both

terminals, high voltage will be on whenever

AC power is turned on. This could be

hazardous in some applications.

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

!!!!!

9040 Classic for REA & M90 Systems - Operation

2 1

2 1

2 1

2 1

2 1

ARCHIVE