Ransburg, Mcv 2 dual purge color changer - maintenance – Ransburg MCV2 Dual Purge Color Changer A10986-XX_A10993-XX User Manual

Page 22

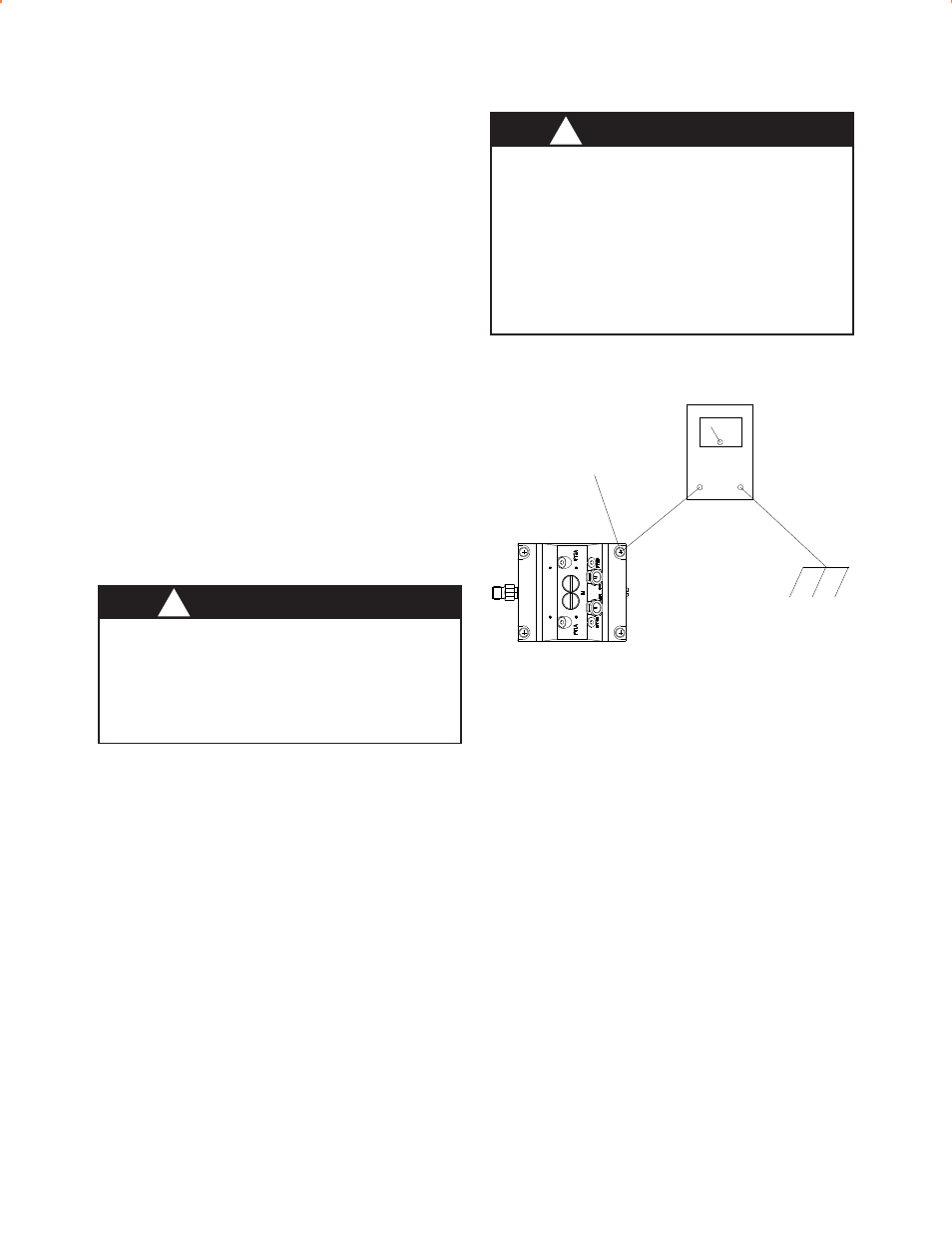

Figure 14: Ground Test

>

ALWAYS test color changer for con-

ductivity after assembly or repair. Proper

conductivity is required to assure entire

color changer can be properly grounded

when installed.

>

NEVER wrap the equipment in plastic to

keep it clean. A surface charge may build-up

on the plastic surface and discharge to the

nearest grounded object. Efficiency of the

equipment will also be reduced and damage

or failure of the equipment’s components

may occur.

WRAPPING THE EQUIPMENT

in plastic will void warranty.

W A R N I N G

!

W A R N I N G

!

9. There should be no more than 6 bubbles

per minute coming from the outlet of the hose

that is submerged.

10. If there are more than 6 bubbles per minute,

remove the color valve assemby, replace the

valve seat (77367-00) and reinstall color valve

assembly. If the new seat does not correct the

problem, either the manifold block or color valve

assembly is defective.

11. Proceed to the next color valve and repeat

Steps 2 thru 11.

12. When all the color valves are checked out,

then check the purge valve assembly repeating

Steps 2 thru 11.

13. Once all valves are operational, deactivate

the 3-way valve, and then disconnect the air

lines used for testing from the color changer.

14. With an ohm meter, check for conductivity

between the top plate of the purge valve and

the output plate on the color changer. There

should be 10 ohms or less between the two

points (see Figure 14).

END PLATE BOLT

OHMS

EARTH GROUND

(TRUE)

10

0

MCV 2 Dual Purge Color Changer - Maintenance

19

CS-05-01.9

Ransburg