Operation, Ransburg, Operating instructions – Ransburg MCV2 Dual Purge Color Changer A10986-XX_A10993-XX User Manual

Page 16: Mcv 2 dual purge color changer - operation

OPERATION

OPERATING

INSTRUCTIONS

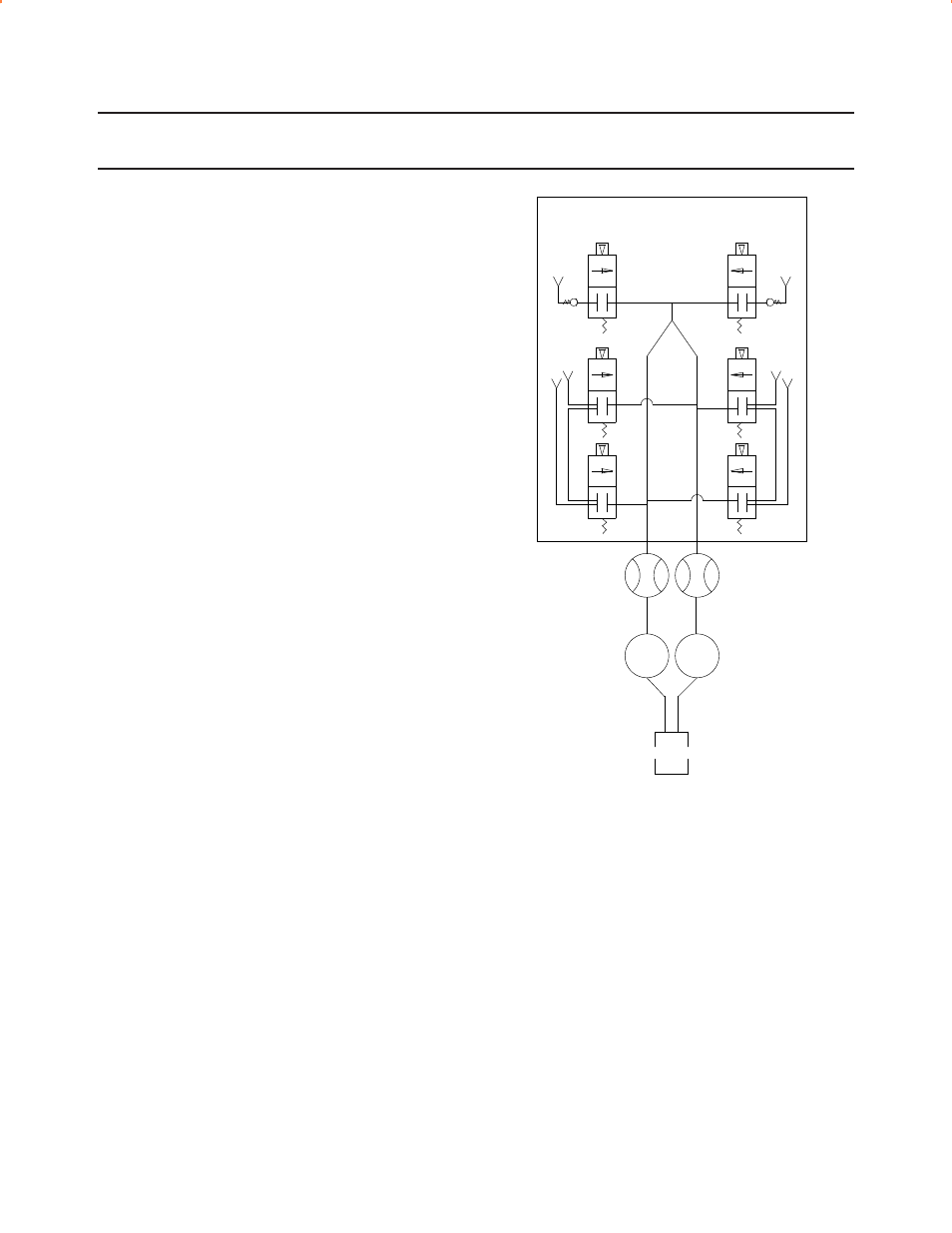

Each slice of the block contains 2 colors, one for

each side of the slice. There are two valves on

each side which are daisy chained internally. This

allows one inbound color line and one outbound

color line run from a paint supply to the dual

purge stack rather than two lines and two returns

for each color. This design uses half the tubing

normally needed for the dual purge applications.

However, there are two (2) 4mm ODT trigger lines

to open the valves to feed line A or line B.

The stack should be mounted as close to the

applicator as possible to minimize the waste ma-

terial left in the tube between the stack and the

applicator. An air push may be used to minimize

the material waste. However, this requires the

applicator to have a regulator on-board to control

the fluid pressure and flow to the applicator while

air is pushing. Both the Evolver and the RMA-202

have optional on-board fluid regulators available.

The normal function would be to have only one

trigger open at a time per side A or B. If more than

one trigger is opened per side, material contam-

ination will occur. The exception is the solvent

air chop that is required for cleaning the internal

porting of the stack.

An example is while Color 1 Trigger A is actuated

which would be supplying an applicator, side B is

being cleaned from the purge stack to the dump

of the applicator. Once cleaning is complete, any

color may be loaded into line B.

Figure 6 shows a typical Color Changer Schemat-

ics to prevent back flow of material.

Figure 6: Color Changer Schematics

FLOW METER

FLOW METER

LINE A

LINE B

FLUID REGULATOR

LINE A

FLUID REGULATOR

LINE B

COL

OR

2

O

U

T

COL

OR

2

IN

COL

OR

1

IN

COL

OR

1

O

U

T

SO

LV

ENT

MCV II DUAL PURGE

M

AI

N A

IR

SPRAY DEVICE

LINE A

SPRAY DEVICE

LINE B

SPRAY DEVICE

MCV 2 Dual Purge Color Changer - Operation

13

CS-05-01.9

Ransburg