SPP Pumps Auto Prime Q Series - Workshop Manual User Manual

Page 34

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 34 of 36

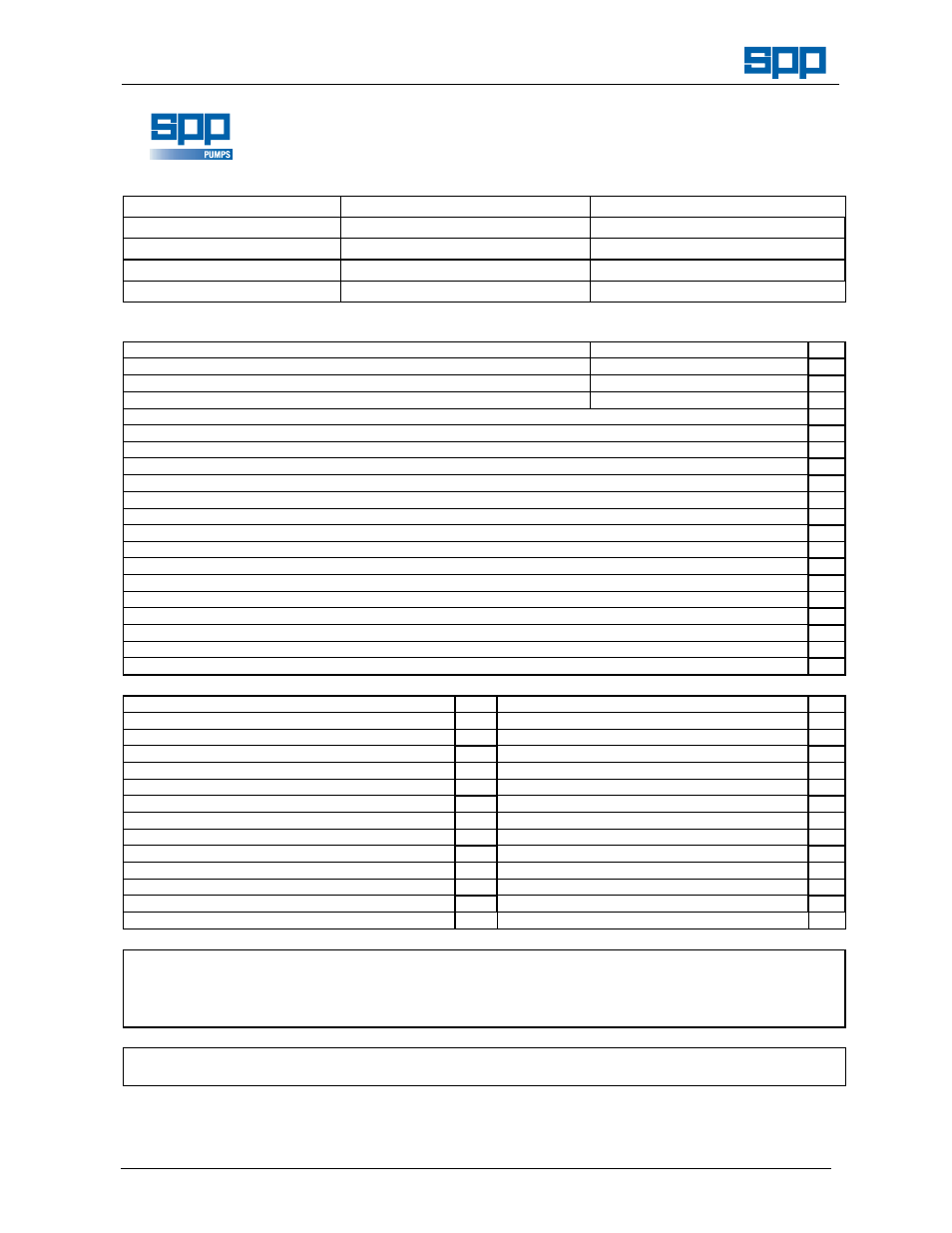

AUTOPRIME Pump 'Q' Range

BUILD, TEST & PDI CHECK SHEET

Part 1 Identification

Pump Type:

Engine S/No:

Engine Type:

Vac. Pump No.

Solenoid Valve ID No:

Control Box ID No:

Test Date:

Test Engineer:

Hours Run:

PDI Date:

Inspector:

Set Serial No.

VIN:

Part 2 Test (tick when complete)

Check engine oil and check for leaks

Use 15w40 oil

Fill coolant system and check for leaks

50/50 antifreeze mixture

Fill Coalescer sump with oil and check for leaks

10w30 oil

Fill seal oil bottle and check for leaks

HD10 oil

Check volute drain valve and non return valve are fully closed

Fill fuel tank with diesel until gauge starts to register (about 1/8th tank)

Start pump

Disengage No.28 wire at vacuum pump

Set engine speed to 2200rpm

Reconnect No.28 wire allowing vacuum pump to engage

Connect Bauer couplings with suction valve fully closed

Perform dry vacuum test. Obtain full vacuum (-9m +/-0.5m). Turn unit off and check for air leaks at pump. Gauge should not drop.

Open volute drain valve and allow vacuum to decay. Close drain valve.

Open suction and discharge valves. Start unit and allow to prime. (Control box LEDs should indicate status if fitted)

Check Speed with Vacuum pump engaged and both valves fully open. (Should be 1950 rpm or more)

Clutch timer should disengage vacuum pump after about 1.5 minutes

Close discharge valve fully check maximum head (see chart or test curve)

Open discharge valve and allow constant re-prime by opening suction bled valve

Check for excessive exhaust vibration (adjust speed +/- 50 rpm to eliminate)

Finish test and drain volute

Part 3 PDI Check (tick when complete)

Tyre Pressure (RT = 55psi +/- 3psi)

All drain valves (volute, NRV, Coalescer, engine) closed

Brake operation (smooth; dose not hit Bauer)

All doors fit and lock, cleanliness, foam fixing

Rear prop operation

Paint finish

Battery mounting and cable connections

Safety notices and labels

Battery fluid levels

Nameplates

Electrical test

Manual and lighting cable included

Fuel filler and gauge

Check unit against GA drawings DN21869,70 or 71

Vacuum pump belt tension

GA drawing issue No.

Engine oil level and leaks and filters

VIN Plate attached and stamped

Seal oil level and leaks

Do the trailer lights work if fitted

Air filter pipes

Is the VIN No. engraved on the canopy

Exhaust mountings, stressed brackets and leaks

Are the pod mounting bolts fitted with sealant

Coalescer oil level, leaks and filters

Priming filter

Engine coolant level and leaks

Part 4 Comments

Notes

Form to remain with unit until despatch

Form to be retained after despatch