8 chassis & fuel tank assembly – SPP Pumps Auto Prime Q Series - Workshop Manual User Manual

Page 22

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 22 of 36

7.

Position the drive belts over the pulleys and

fit the belt tensioner (7) to the bearing

housing, adjust to give slight tension to the

belts.

8.

Fit the vacuum hose between the solenoid

valve and the vacuum pump using hose

clips to ensure an airtight joint.

(Refer to Lifter Parts Diagram 7.12.1)

9.

Fit the lifter (1) to the pump bearing housing

using the three screws (2) with washers (4).

10.

Fit the lifter support strut to the pump

casing using bolt (6) and washer (7), do not

tighten at this stage.

11.

Fit the spacer (5) between the lifter and the

strut and fit bolts (8) with washer (9) and

nuts (10). Tighten all bolts securely.

7.8 Chassis & Fuel Tank Assembly

7.8.1 Chassis Assembly Notes

The support leg (22), light bracket (17) and

security bracket (19) are not fitted when

building a Q pump unit as a pod.

For trailers intended for use in France, the

pedestrian guard rail must be fitted.

For trailers that are to be used in Europe

the European VIN number plate must be

fitted.

For single fuel tanks the drain hose kit

comprises a 90deg hose socket in place of

the ‘T’ piece used with twin tanks.

The drain hoses for the pump, coalescer

and engine are specified with their

assemblies.

7.8.2 Chassis Assembly Instructions

1.

Mount the chassis (1) on suitable support

stands.

2.

Fit the sound insulation kit (2) to the

chassis.

3.

Fit foam strip (3) to the chassis in three

positions on under the fuel tanks and at

each end of the fuel tank channels.

4.

Fit foam strip also to the inside of the two

shrouds (1 & 10).

5.

Prepare the fuel tanks by fitting the short

drain hoses (26 or 27) to the fuel tanks and

secure with hose clamps.

6.

Fit the fuel gauge and the fuel pipe fitting

(Fuel Tank diagram items 4 & 5) to the

primary fuel tank.

7.

Feed the drain hose through the slots in the

chassis frame members and retain the fuel

tanks within the side channels using the

square washers and fasteners specified.

8.

Fit the remaining items for the fuel tank

drain assembly. Use Loctite 577 sealant on

all screwed pipe connections

9.

Fit the hose tails (28 & 29) and plugs (30 &

31) to the drain points on the chassis.

10.

Fit the side shrouds (9 & 10), but leave the

front and rear shrouds (14 & 15) for fitting

after the pump and engine unit have been

installed, tighten all bolts.

After Pump Installation Is Complete:

11.

If the chassis is not already mounted on

suitable supports, lift the unit and provide

support to give access to the eight

mounting hole un the underside and located

in pairs in the centre or each side and end.

12.

Remove all dirt and grease, apply

degreasing agent to each of the mounting

holes to clean the threads and surrounding

area for application of sealant.

13.

Clean the shorter thread end of the

mounting studs and apply Loctite 577 to

this thread, fit the studs to the chassis

tighten to approximately 61 Nm.

14.

Apply a continuous bead of Loctite 5220

around each stud to seal the gaps in the

welds etc.

15.

For skid mounted units, mount the chassis

on the skid (35) and retain with washers

and nuts.

16.

For trailer mounted units, fit the support leg

(22) and mount the chassis on the required

trailer and retain with washers and nuts.

17.

For trailer units, fit the lighting and security

brackets (17 & 19), note that the two

screws securing the rear shroud must be

replaced by longer screws (18).

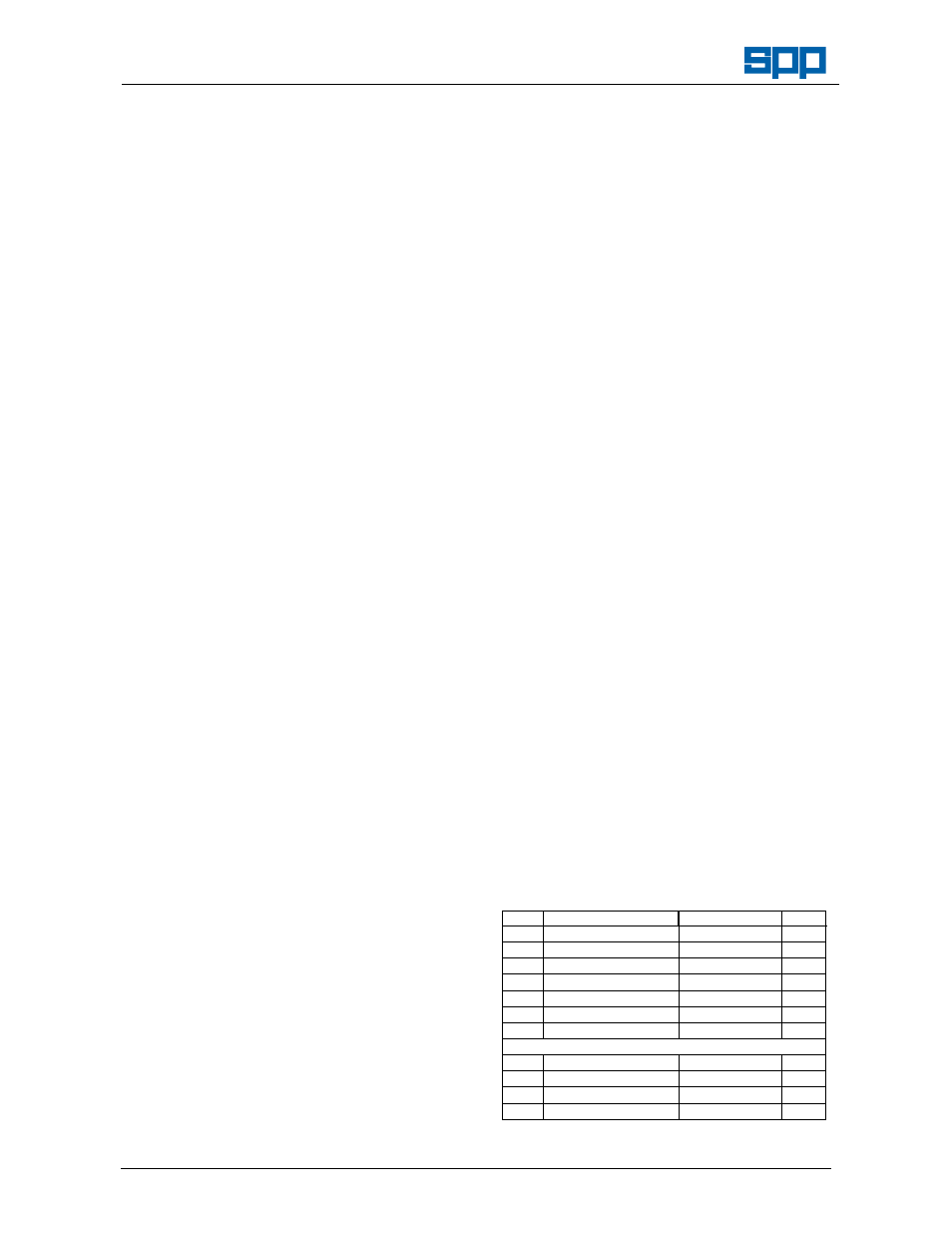

7.8.3 Fuel Tank Assembly

ITEM

DESCRIPTION

PART No

QTY

1

Primary Fuel Tank

Assy.

21340

1

2

Fuel Tank Only

21321

1

3

Filler Cap

21343

1

4

Fuel Gauge

21341

1

5

Fuel Pipe Fitting

21342

1

6

Gasket Fuel Pipe

Fitting

21674

1

7

Screw M5 x 12

MS1267

6

Secondary Fuel Tank and Air Vent Pipe – not illustrated

Secondary Fuel Tank

21322

1

Sec. Tank Vent Pipe

21636

900mm

1

Cable Base

TY1029

3

Cable Tie

TY1000

3