7 pump end final assembly – SPP Pumps Auto Prime Q Series - Workshop Manual User Manual

Page 21

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 21 of 36

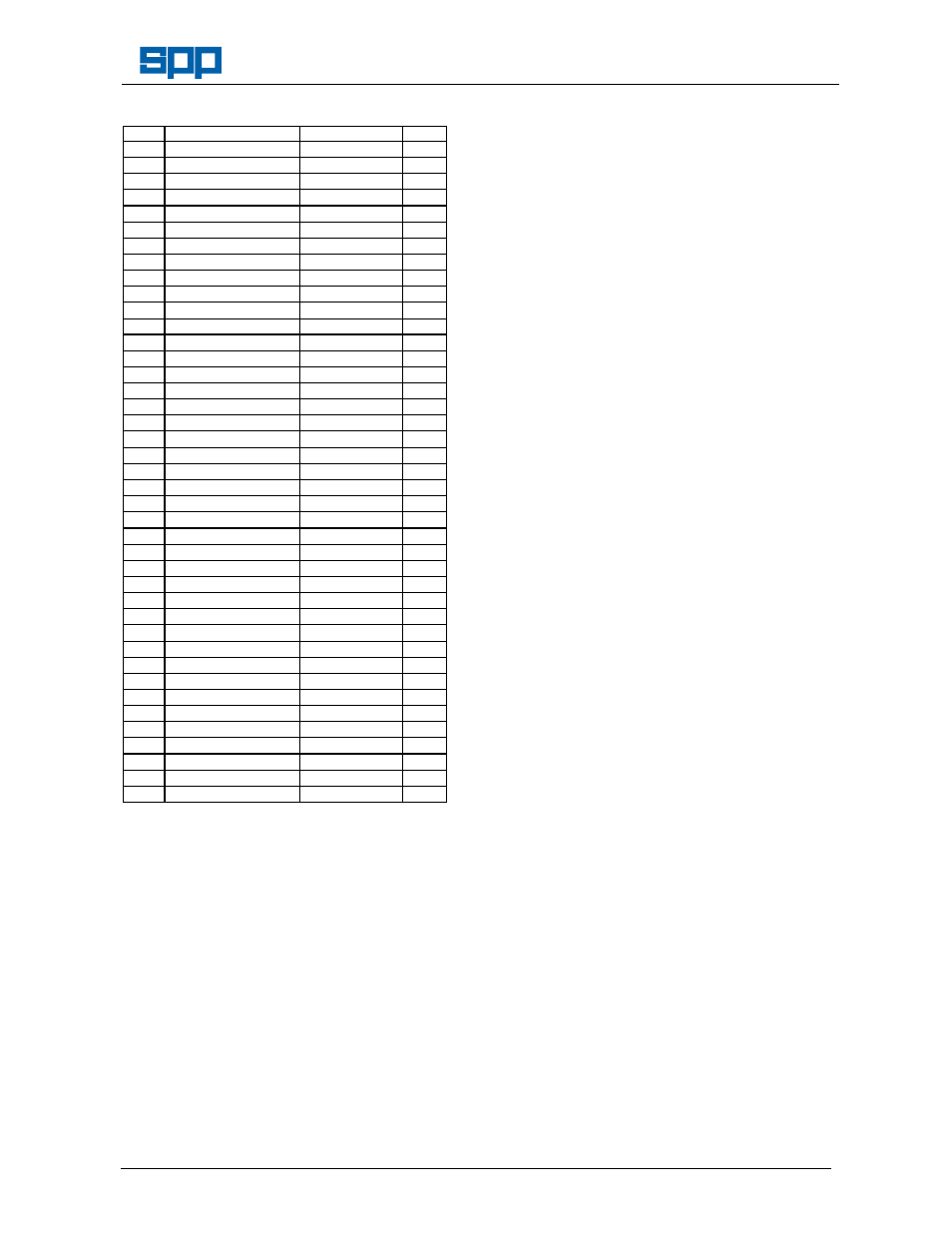

7.6.2 Priming Tank Parts List

imin

ITEM

DESCRIPTION

PART No

QTY

1

Inlet Duct - Q#100

18204.123

1

1

Inlet Duct - Q#150

17083.123

1

1

Inlet Duct - Q#150M

25529.123

1

1

Inlet Duct – Q#200

18104.123

1

2

Gasket

SY5004397

1

3

Tank – Priming

17084.524

1

4

Housing – Filter

13661.524

1

5

Gasket-P/Tank-Filter

13934

1

6

Stud-M8 x 25

21816-257-962-6

8

7

Nut – M8

21882-672-958-6

8

8

Washer Spring M8

21174-305-927-9

8

10

Filter Block-Knitmesh

13796

1

11

Carrier – Filter

13662.524

1

12

Stud – M6 x 260 lg

13798

1

13

Nut – M6 Self Locking

SY9509863

1

14

Stud – M6 x 65

13799

3

15

Washer – M6 Flat

21172-209-342-6

3

16

‘O’ Ring – 79.5 I/d x 3

25154-079-017-1

1

17

Knob – M6 Scallop

13797

3

18

Element – Filter

14006

1

19

Retainer – Filter

14470

1

20

Cover – Filter

13663.524

1

21

‘O’ Ring – 87 I/d x 3

13942

1

22

Stud M8 x 25

21816-257-962-6

3

23

Nut M8

21882-672-958-6

3

23a

Washer Spring M8

21174-305-927-9

3

24

Screw M12 x 30

21863-218-959-1

6

24a

Washer Spring M12

21174-307-927-3

6

24b

Plain Washer M12

21172-212-342-2

6

25

Adapter – 1” BSP

14176

1

25a

Fibre Washer

22115

1

26

Valve – Solenoid

13794

1

27

Bush-Red 1” x ¾” BSP

25243-706-906-5

1

28

Cap – Breather

13925

1

29

Elbow-1” BSP x 90 M/F SY9209045

1

30

Elbow-1” BSP x 45 M/F SY9209340

1

31

Pipe Adapter

SY3734296

1

32

Superclamp-40/43mm SY3804409

2

33

Vacuum Hose – 32mm

20094

1

34

Nut M8 Self Lock

18173

4

35

Stud M5 x 50mm

21815-265-955-8

4

Based on 23531 as on 16-09-05

7.6.3 Priming Tank Assembly Instructions

Note:This may be done before fitting the Inlet duct

(1) to the pump casing but is best done

after fitting to the pump to ensure stability

and ease of assembly.

1.

Insert the knitmesh filter (10) into the

priming tank (3)

2.

Fit the gasket (2) to the inlet duct (1), mount

the priming tank in position and fasten in

place with screws (24) and washers (24a &

24b).

3.

Fit the long stud (12) to the filter carrier (11)

using the nut (13) to lock it into position and

fit ‘O’ ring (16) to filter carrier (11).

4.

Fit the carrier assembly to the filter housing

(4) and retain by three studs, washers and

nuts (22, 23 &23a).

5.

Feed the fine filter element (18) into the

housing and fit the filter retainer (19), do not

over-tighten the retainer as this may

damage the filter element.

6.

Fit the ‘O’ ring (21) to the filter cover (20)

and fit this to the filter housing, retained in

position with three washer and knobs (15 &

17).

7.

Mount the filter assembly on the priming

tank using gasket (5) and eight studs

washers and nuts (6,8 & 7).

8.

Fit the fibre washer (25a) on the adaptor

(25) and using PTFE tape to seal it fit this to

the filter carrier.

9.

Again using PTFE tape fit the solenoid

valve (26) to the adaptor having fitted the

bush (27) and breather cap (28) to the

solenoid valve.

10.

Finally using PTFE tape to seal the threads

fit the pipe fittings (29, 30 & 31) to suit the

required direction of the vacuum hose.

7.7 Pump End Final Assembly

(Refer to Pump Parts Diagram 7.3.2)

1.

If the Inlet duct was not fitted to the pump

casing for assembly of the priming tank, fit

the priming tank assembly to the pump

using ‘O’ ring (57) to seal the joint and

retain by studs washers and nuts (54 55,

55a & 55b).

(Refer to Coalescer Parts Diagram 7.4.3)

2.

Fit the vacuum pump to the coalescer using

the gasket 33 and retain by studs, washers

and nuts (34 36 & 37).

3.

Fit the coalescer assembly complete with

the vacuum pump to the pump bearing

housing using studs (35) and washers and

nuts (36 & 37).

(Refer to Drive Belt Parts Diagram 7.11.1)

4.

Fit the key (pump parts diagram item 11) to

the pump shaft, fit the Taperlock bush (2) to

the pulley (1) and slide this assembly on to

the pump shaft.

5.

Align the pulley with the vacuum pump

pulley and tighten the grub screws to lock

the pulley into position on the shaft.

6.

Remove each grub screw in turn and apply

Loctite 577 to the threads, refit and tighten.