SPP Pumps Auto Prime Q Series - Workshop Manual User Manual

Page 16

Manual No/Rev

W72-021E / 8

Workshop Manual for

AUTOPRIME Q Range Pump Units

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 16 of 36

7.3.4 Pump Assembly Procedure

1.

Apply a light smear of grease to the non-

drive end bearing assembly.

2.

Locate the outer race of non-drive end,

roller bearing inside the bearing housing

and push it through the drive-end bearing

diameter.

3.

Set it square with the bore and push it

home to seat fully against the shoulder at

the pump end of the bearing housing.

4.

Insert the bearing spacer into the bearing

housing.

5.

Heat the inner ring of the non-drive end,

roller bearing to 110°C and place over the

pump end of the shaft to locate fully against

the shoulder on the shaft.

6.

Heat the drive-end ball bearings to 110°C

and place the first bearing over the shaft

ensuring that the thicker end of the inner

ring is facing the shoulder on the shaft.

Press the bearing home and ensure that

the bearing abuts the shoulder and is

seated squarely on the shaft.

7.

Heat as above and place the second

bearing on the shaft but with the thinner

end of the inner ring facing the first bearing.

Press home to abut fully with the first

bearing.

8.

When cool, apply grease to pack the

bearings to fill about half the space

between the balls, and rotate the bearings

several times to distribute the grease

evenly.

9.

Place the bearing housing in the vertical

position and lower the shaft into the bearing

housing.

10.

Press home the shaft until the drive-end

bearings are seated fully on the bearing

spacer.

11.

Fit the locknut to the shaft and tighten to

200Nm.

12.

Lubricate and fit the O ring in the groove

and fit the lip seal with its lip facing inwards

in the housing on the bearing cap.

13.

Fit the bearing cap and secure with four M8

x 25 screws.

14.

Invert the bearing housing, lubricate and

insert the stationery element of the

mechanical seal in it’s housing on the pump

end of the bearing housing.

15.

Lubricate and fit the rotating assembly of

the mechanical seal on the shaft, add the

washer and circlip, compress the seal and

locate the circlip in it’s groove.

Take great care when handling the

mechanical seal parts, do not touch the

sealing faces and use only lint free wipers if

cleaning is required. If lubrication is

required to assist assembly us clean and

thin oil only.

16.

Attach the pump casing to the bearing

housing by attaching the 8 M8 nuts to the

bearing housing studs.

17.

Replace the back wear plate and secure

with 6 M12 nuts screwed onto the studs at

the bearing side of the pump casing.

18.

Lubricate and insert the second stationery

element of the mechanical seal in it’s

housing on the pump end of the bearing

housing.

19.

Lubricate and fit the rotating assembly of

the mechanical seal on the shaft, add the

washer and circlip, compress the seal and

locate the circlip in it’s groove.

20.

Replace the taper key and place the

impeller over the shaft taper.

21.

Ensure the shaft is locked and Insert the

socket screw into the impeller and the shaft.

Then unlock the shaft using the C spanner.

22.

Insert the front wear plate complete with O-

rings into the pump casing and screw nuts

(M16) onto the studs on the front wear plate

of the pump casing.

23.

Fit the mechanical seal lubrication tank and

connect the pipes as shown on the

diagram.

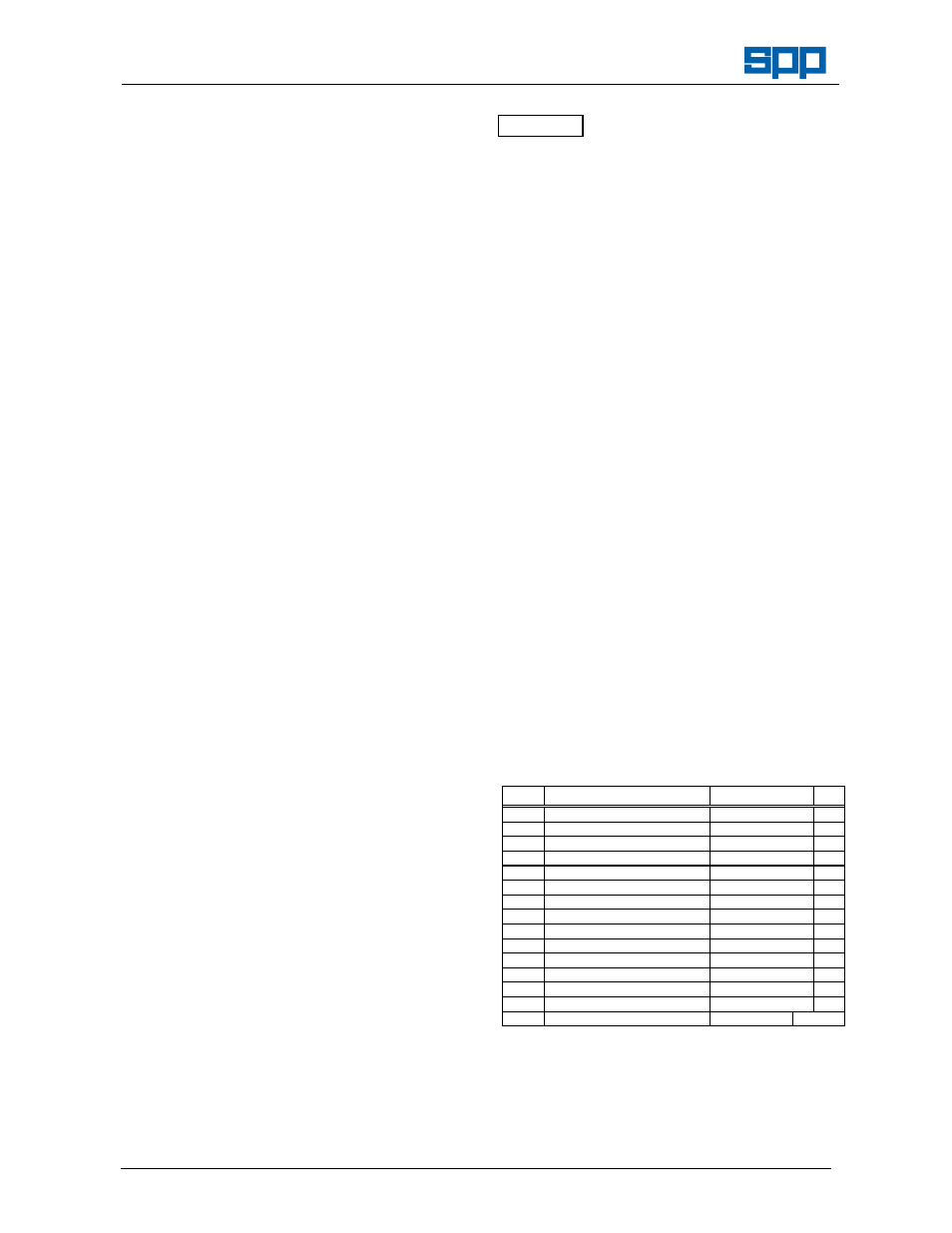

7.3.5 Seal Lubrication System Parts List

ITEM

DESCRIPTION

PART No.

QTY

1

Washer M10

21172-211-342-5

2

2

Spring Washer -M10

21174-306-927-6

2

3

Cable Tie

TY1003

2

4

Cable Base

TY1029

2

5

Hose Tail

12149

1

6

Bolt M10 x 90

12204

1

7

Plastic Tube

12501

1

8

Bracket - Oil Bottle

14640.221

1

9

Spacer Set

14641

1

10

Oil Bottle

15430

1

11

Cap - Oil Bottle

15431

1

13

Hose Clip 7/8-1.1/2

25742-205-000-9

1

13a Hose Clip

05837

1

14

Bolt - M8 x 16 Self Locking

18163

4

15

Hose ¾”

16882

460mm

ATTENTION