Inspection & testing, 11 spark arrestor – 3ce1, 13 hose fittings – SPP Pumps Auto Prime Q Series - Workshop Manual User Manual

Page 33

Workshop Manual for

AUTOPRIME Q Range Pump Unit

Manual No/Rev

W72-021E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 33 of 36

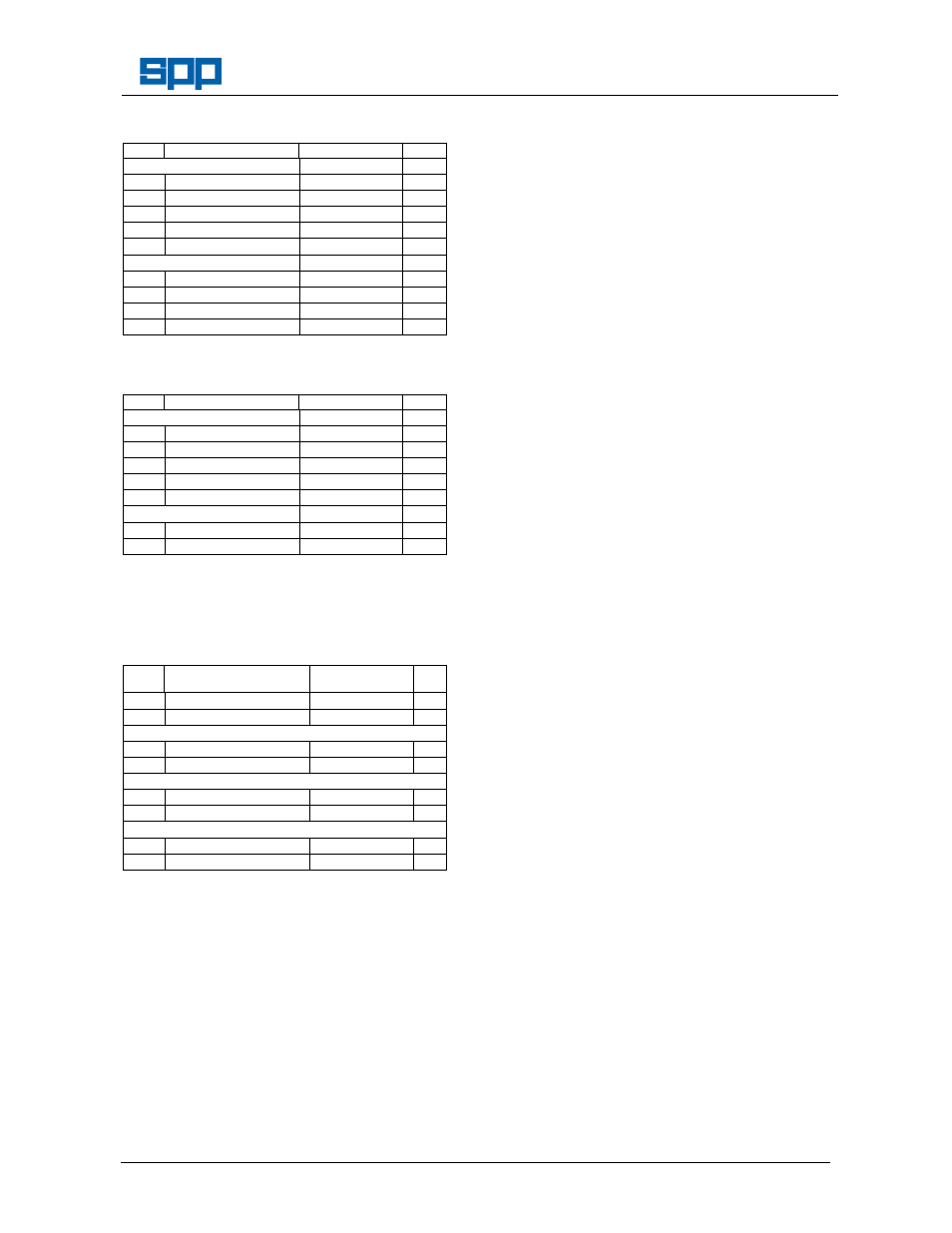

9.11 Spark Arrestor – 3CE1

ITEM

DESCRIPTION

PART No

QTY

Spark Arrestor Assembly:

24341

1

1

Spark Arrestor

25017

1

2

Support

21334

2

3

Bolt M8 x 25 Self Lock

18165

4

4

Nut M8 Self Lock

18173

4

5

Inlet Pipe

25018

1

Chalwin Valve Assembly:

24342

1

6

Pipe Clamp

25288

1

7

Chalwin Valve

21168

1

8

Stud M10 x 65

21815-318-347-7

1

9

Nut M10 Self Locking

18174

1

9.12 Spark Arrestor – 4LE1 & 4LE2

ITEM

DESCRIPTION

PART No

QTY

Spark Arrestor Assembly:

21312

1

1

Spark Arrestor

25017

1

2

Support

21334

2

3

Bolt M8 x 25 Self Lock

18165

4

4

Nut M8 Self Lock

18173

4

5

Inlet Pipe

25019

1

Chalwin Valve Assembly:

21313

1

Chalwin Valve D40BS

21168

1

6

Hose Clip

25742-212-000-3

1

9.13 Hose Fittings

Autoprime Q range pumps are supplied as

standard fitted with Bauer hose connections but if

damaged or lost the following parts will be

required.

ITEM

DESCRIPTION

PART No

QT

Y

1

Stud M16 x 35

21815-461-347-6

12

2

Nut M16 Self Locking

18176

12

For QI 100 Pumps

3

4” BS10D 45Deg Female

16394

1

4

4” BS10D 45Deg Male

19102

1

For QI 150 Pumps

5

6” BS10D 45Deg Female

13693

1

6

6” BS10D 45Deg Male

19103

1

For QI 200 Pumps

7

8” BS10D 60Deg Female

14536

1

8

8” BS10D 60Deg Male

14537

1

Based on 21946, 21927 and 21947 as on 11-09-05

10. INSPECTION & TESTING

Note: If the unit has received a major overhaul, do

all the checks listed on the Pre Delivery

Inspection (PDI) form.

If some parts have been disassembled, do

the checks relating to the parts that have

been worked on.

Check the engine coolant and oil levels and

the pump seal oil level before starting the

engine.

Confirm that the battery is fully charged and

the fluid levels are correct.

Confirm that the fuel tanks contain sufficient

fuel for the testing.

Where new drive belts have been fitted,

check and adjust the drive belt tension after

the engine has been run for an hour.

Pre Delivery Test Procedure

Following major overhaul or maintenance

work it is advisable to check and test the unit

as outlined in the Build, Test and Pre-

Delivery Check Sheet on page 32.

Before towing check:

Wheel nuts to ensure tightness.

Tyre pressures and tyre condition.

Towing hitch condition and security.

Brake adjustment.

Trailer draw bar fasteners.

Axle fasteners.

Lifter and lifter stay fasteners

Engine to pump & chassis fasteners.