Water supply – Fulton Ancillary Equipment SteamPac Unfired Steam Generators User Manual

Page 17

Fulton Thermal Corp.*SteamPac Unfired Steam Generators Manual* Version 2010-0201

Page 17

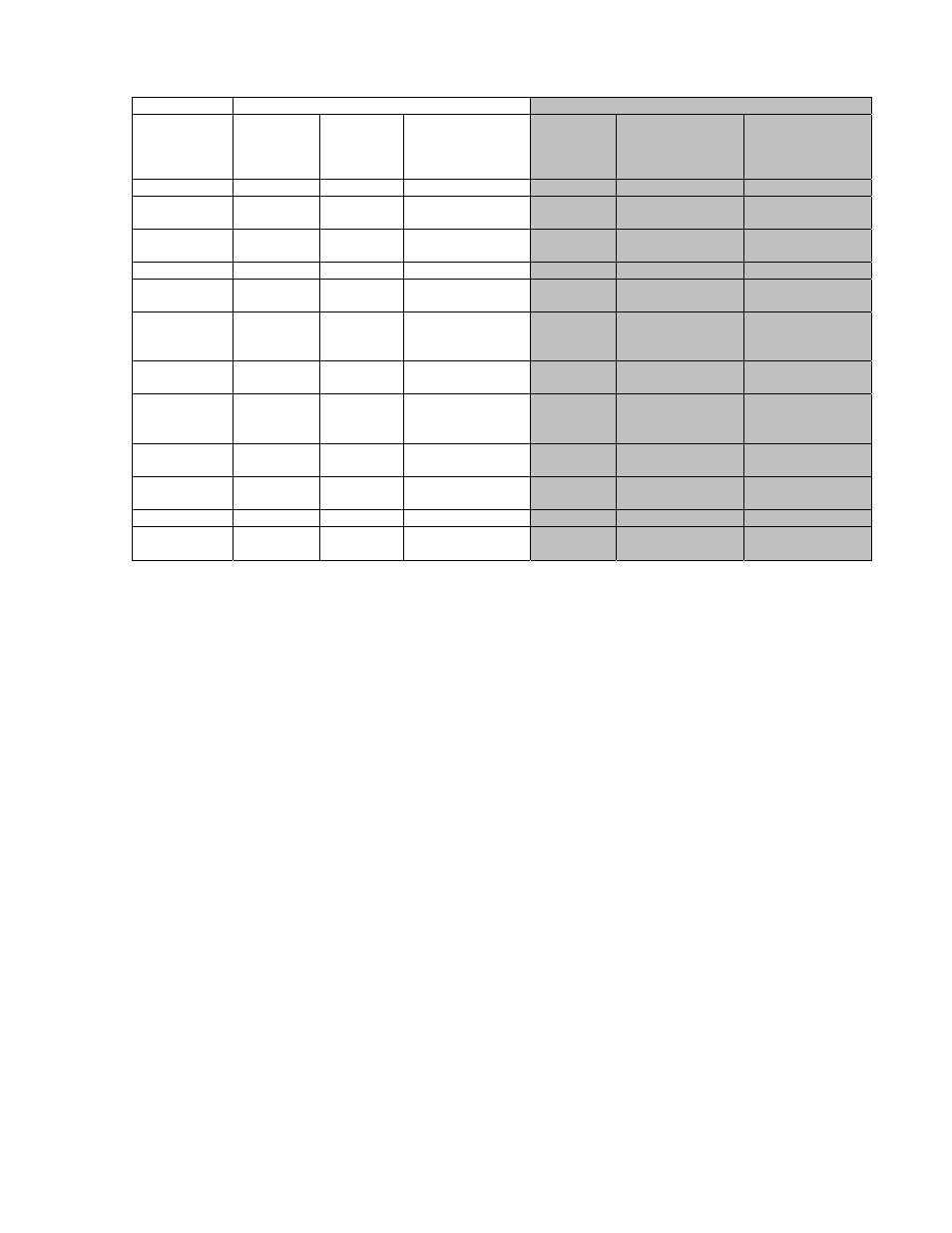

Carbon Steel

Stainless Steel

Parameter Feedwater

Vertical

Boiler/

SteamPac

Water

Horizontal

Boiler/SteamPac

Water

Feedwater

Vertical

Boiler/SteamPac

Water

Horizontal

Boiler/SteamPac

Water

pH

7.5-9.5 8.5-10.5 8.5-10.5 6.0-9.5

8.5-10.5

8.5-10.5

Feedwater

Temperature

140F* ---

---

140F*

---

---

Hardness as

CaCO3

< 2ppm

< 10 ppm

< 15 ppm

< 2ppm

< 10 ppm

< 15 ppm

Chlorides

--- ---

---

---

50 ppm

50 ppm

Total

Alkalinity

---

< 300 ppm

< 500 ppm

---

< 300 ppm

< 500 ppm

Total

Dissolved

Solids

--- <

2000

ppm

< 3000 ppm

---

< 2000 ppm

< 3000 ppm

Suspended

Solids

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

No visual

turbidity**

Total

Organic

Carbon

No sheen

No foam +

No sheen

No foam +

No sheen No

foam +

No sheen

No foam +

No sheen No

foam +

No sheen No

foam +

Iron

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Colorless

liquid++

Dissolved

Oxygen

<1 ppm*

ND

ND

< 5 ppm

ND

ND

Visual Oil

ND ND

ND

ND

ND

ND

Conductivity

(

μS/cm)

---

< 2985

< 4477

---

< 2985

< 4477

NOTES:

*Feedwater temperatures below 200

o

F will require an oxygen scavenger

** Suspended solids: Take a water sample. After the sample sits for 10 minutes, no solids should be visible.

+ Total Organic Carbon: Take a water sample. Shake vigorously for 30 seconds. No sheen or foam should be visible.

++ Iron: Take a water sample. Hold the sample against a white background. The water should have no visible yellow, red or

orange tinge.

ND: None Detected.

11. Water Supply

a) The quality of the water used in the boiler will affect the life of the elements and pressure

vessel and it is strongly recommended that a competent water treatment company be

consulted prior to the installation of the boiler. Elements/PV damaged due to adverse

water conditions will not be replaced under warranty.

b) Natural feedwater supplies contain solids and dissolved gases. These may promote

scale, foaming, corrosion, and/or poor steam quality. To prevent this, feedwater must be

studied individually and treated accordingly. The treatment should provide quality

feedwater to the boiler such that corrosion and deposition in the boiler will be minimized.

Thermal cycling, dissolved oxygen, high or low pH can all be major causes of corrosion.

Untreated hardness is the major cause of scale deposits. Poor quality feedwater requires

increased blowdown and increased chemical treatment costs to prevent boiler corrosion

and scaling.