Maintenance – Fulton Caliber (CAL) Condensing Hydronic Boiler User Manual

Page 51

Questions? Please Contact Your Local Manufacturer’s Representative

SECTION 4

CAL-IOM-2014-0129

MAINTENANCE

4-7

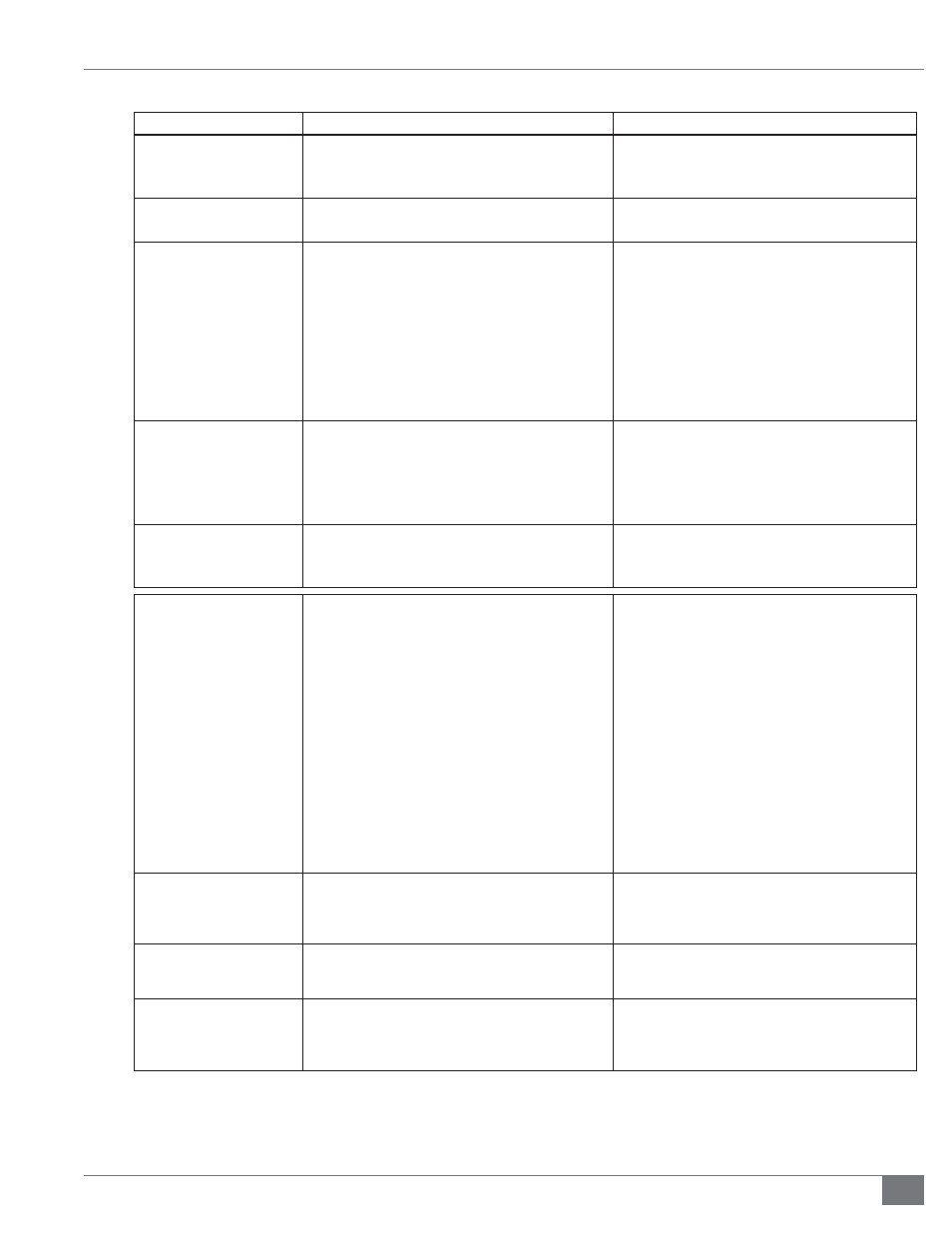

PROBLEM

CAUSE

CHECK/SOLUTION

Manual Reset limit device

trips

Manual Reset Limits include: Flame safeguard, high

or low gas pressure, high temperature limit

DO NOT reset without determining and correcting

the cause. Contact your local representative/

qualifi ed service technician.

Power outage to the boiler

room

Entire boiler system is disabled and de-energized.

When power has returned, the boiler will restart

unless it was in lockout position at time of outage.

Gas Pressure alarm is

annunciated

Either insuffi

cient gas pressure or the gas pressure

to the manifold is too high for safe and proper

operation of the boiler. This shuts down the burner.

When gas pressure is restored, the annunciated

alarm will remain on and the boiler will remain

locked out until the gas pressure switch is manually

reset.

Locate cause and correct. In the event of a high

gas manifold pressure condition, qualifi ed service

personnel must correct the problem before

restarting the boiler.

High water temperature

alarm is annunciated

Boiler water has exceeded both the operating and

high-limit temperature. When the water temperature

falls below the high-limit temperature, the boiler will

remain locked out until the controller is manually

reset.

Locate cause and correct. Once the SOLA control

is reset, the sequence returns to normal operation

provided that the other limits are satisfi ed.

Insuffi

cient fl ow of heat

transfer medium causes

lock out

Boiler requires minimum fl ow; when required fl ow is

resumed, boiler will resume operation.

Identify and correct.

Low Air Flow Supply/

Air Switch Open

Low Air is annunciated if the airfl ow switch detects

low airfl ow through the boiler.

The air switch has been factory set and should not

be adjusted in the fi eld.

An extended low air indicaƟ on does not mean that

the low air switch is defecƟ ve.

Check that blower is powered and feedback plugs

are clipped into the blower.

Check that the blower is clean by observing

through the venturi. Check the blower purge speed

and low fi re speed is correctly displayed on the

touch screen.

Check for obstrucƟ ons in the vent.

Check for obstrucƟ ons in the air inlet.

High Back Pressure Switch

trip/boiler shutdown

Excessive Vent Pressure

This condiƟ on will automaƟ cally recycle, so

the boiler will try to relight. The vent and heat

exchanger should be checked for obstrucƟ ons and

cleaned.

Main fl ame failure during

fi ring period

Main gas control valve is de-energized and the con-

trol goes into “lockout” mode. Flame failure occurs

and the indicator is illuminated.

The programmer must be manually reset.

IgniƟ on Failure

If fl ame rod does not detect the fl ame during the

4-second trial-for-igniƟ on period, the gas valve and

spark igniƟ on are de-energized. At this Ɵ me a safety

lockout occurs.

IdenƟ fy and correct; reset via the SOLA Control.