Installation, Prevent freezing, Prevent oxygen contamination – Fulton Caliber (CAL) Condensing Hydronic Boiler User Manual

Page 17

Questions? Please Contact Your Local Manufacturer’s Representative

SECTION 2

CAL-IOM-2014-0129

INSTALLATION

2-11

!

WARNING

All information in this manual is for

reference and guidance purposes,

and does not substitute for required

professional training, conduct,

and strict adherence to applicable

jurisdictional/professional codes and

regulations.

The boiler must be disconnected at

the boiler shut off valve from the

gas supply piping system during any

pressure testing of the system.

4

CAUTION

Small levels of chlorides and/or sulfur

presence in the combustion air or

fuel will negatively impact the heat

exchanger components. Any presence

of these contaminants will void the

warranty.

Some soaps used for leak testing are

corrosive to certain types of metals.

Rinse all piping thoroughly with

clean water after leak check has been

completed.

3. Appropriate

fl ow rates may be achieved through primary and secondary

fl ow loops. Please refer to Figures 3 - 5 for example systems. Multiple

pumps, valves and heating zones operating at a variety of conditions will

cause system fl ow to vary. System design professionals should consider the

variety of conditions the heating system will experience.

4. Operate the boiler in a closed-loop system using water or water/glycol

(not requiring a make-up water supply). A large amount of improperly

treated make-up water can cause premature failure of the heat exchanger

resulting from scale build up. Scale build up will reduce the effi

ciency and

useful life of the boiler.

5. Caliber boilers use high effi

ciency, small diameter tubing in the water side

of the boiler. Large particulates may become caught in the heat exchanger,

which could result in damage to the heat exchanger. Debris in the piping

must be kept to a minimum; use a suitable strainer upstream of the inlet to

the boiler.

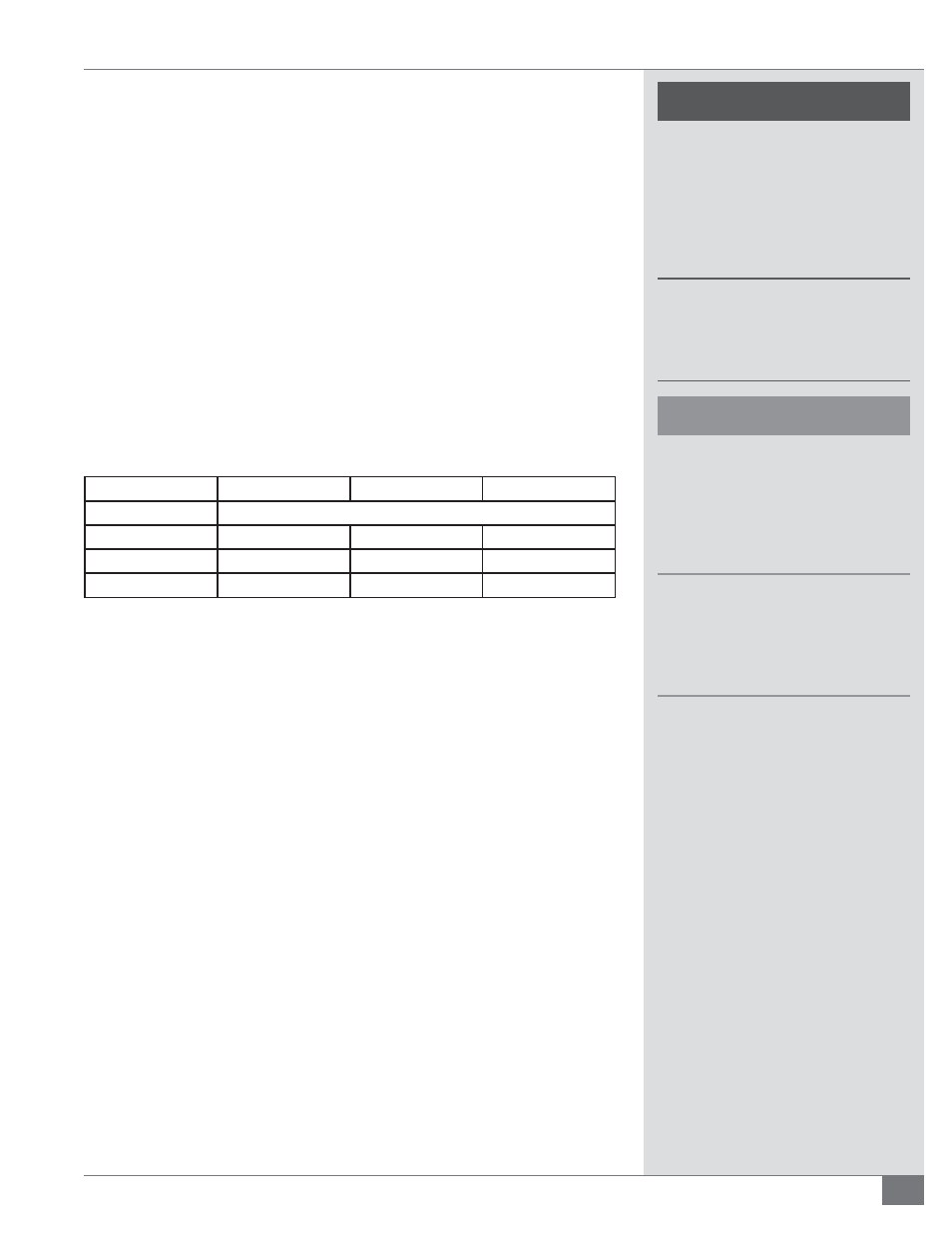

TABLE 3 - RECOMMENDED WATER TREATMENT CHEMICALS

Manufacturer

Fernox

Sentinel

Sotin

Product

Inhibitor

Protector/Alphi 11

X100, X500

Sotin 212

Universal Cleaner

Restorer

X300

--

Sludge Removal

Protector.Restorer

X400

Sotin 212

Prevent Freezing

It is imperative to prevent freezing; adhere to the following:

If a water/glycol mix is to be used in the system, a hazard analysis should

be performed to determine proper use and disposal. No greater than 50%

glycol should be used.

Caliber boilers cannot be placed outdoors. Precautions for freeze

protection are recommended for boiler installations where freezing

potential exists and for installations that will use sealed combustion with

potential for outdoor temperature to fall below freezing point.

Prevent Oxygen Contamination

There are several ways to prevent boiler water oxygen contamination:

Minimize system leaks to minimize make up water requirement

Do not use open tanks or fi ttings

Do not use oxygen permeable materials anywhere in the water system

Repair leaks in the system quickly

Eliminate fi ttings wherever possible