Installation, Sizing air intake and exhaust piping – Fulton Caliber (CAL) Condensing Hydronic Boiler User Manual

Page 23

Questions? Please Contact Your Local Manufacturer’s Representative

SECTION 2

CAL-IOM-2014-0129

INSTALLATION

2-17

is used, the fi rst 8 inches (204 mm) must be CPVC material. Venting

installation must comply with National Fuel Gas Code, ANSI Z233.1, Part 10

or applicable provisions of local building codes.

2. Do not utilize automatic vent dampers or barometric dampers with the

Caliber boiler. Because the exhaust system operates at a positive pressure,

utilizing dampers could result in exhaust gases leaking into the boiler

room.

3. The exhaust line must be sloped down toward the boiler with a pitch of

at least 1/4” per foot. Failure to do so can result in a condensate pocket,

which can result in an inoperative boiler. There must be no low spots in the

exhaust pipe, as this can also result in a condensate pocket. A high spot is

acceptable, provided the pitch from the high spot is maintained back to

the boiler. Always avoid rigid connections between piping and structural

members of the building. The exhaust vent installer should be familiar

with Federal Codes as well as local codes and regulations.

4. Follow vent manufacturer’s instructions for installation of exhaust venting.

Refer to Table 5 for acceptable venting materials.

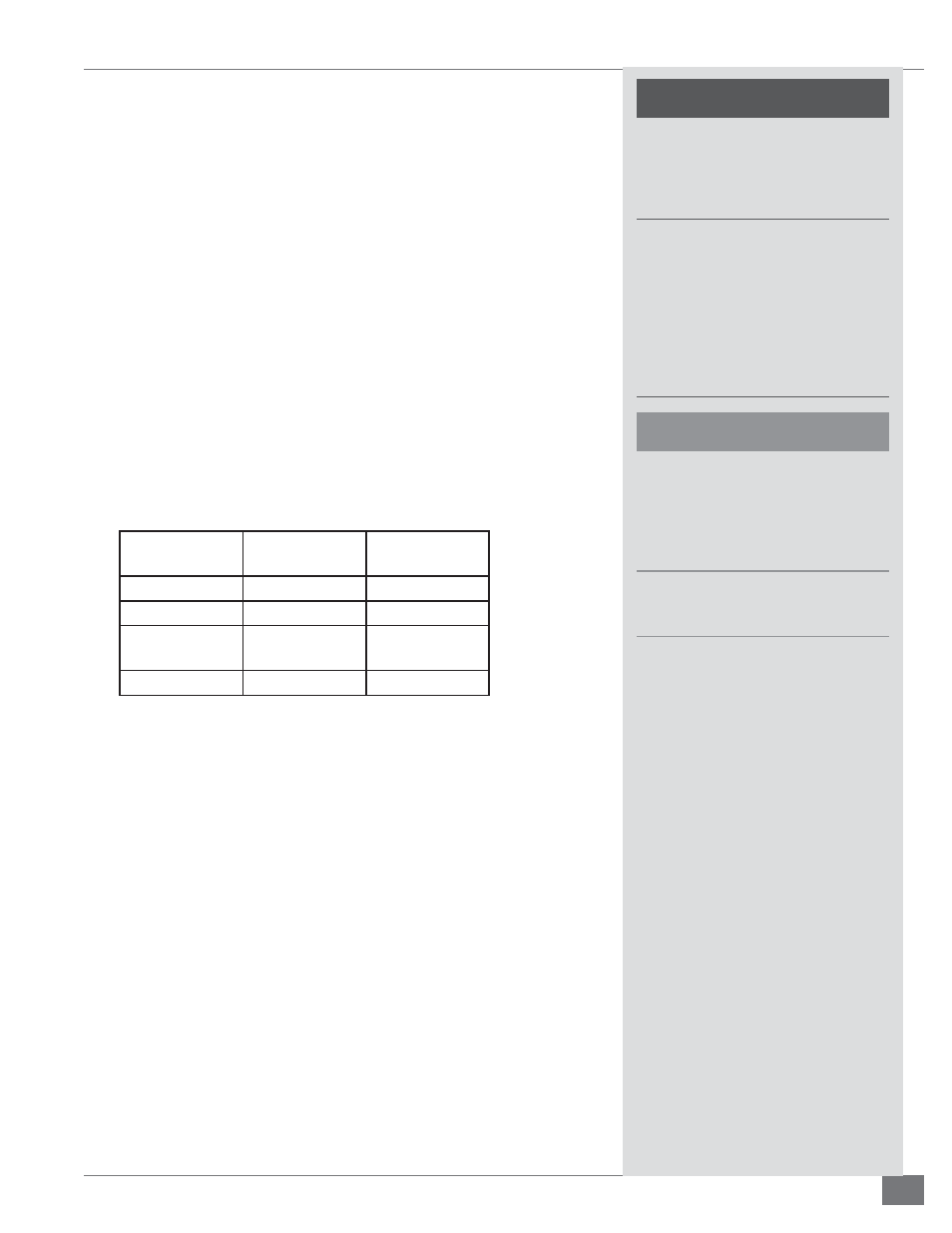

TABLE 5 - ACCEPTABLE VENTING MATERIALS

Venting

Material

Max. Flue

Temperature

Max. Water

Setpoint

PVC

200 F (93 C)

200 F (93 C)

CPVC

200 F (93 C)

200 F (93 C)

Polypropylene

(InnoFlue)

248 F (120 C)

200 F (93 C)

AL294C

550 F (287 C)

200 (93 C)

Note: Fulton accepts no liability for installation of any venting, including the selection of venting materials.

If PVC is used, the fi rst 8” must be CPVC. Do not use cellular/foam core pipe.

5. Stainless steel or galvanized steel pipe is recommended for all condensate

drain piping. Be aware that condensate drain piping can be as hot as the

exhaust stack on the boiler, and precautions should be taken to ensure this

pipe would not cause burns or other injuries to personnel that may be in

the boiler room.

6. Ensure that the condensate drain piping will not be exposed to

temperatures where water/condensate will freeze in the lines.

Sizing Air Intake and Exhaust Piping

CATEGORY II OR IV INSTALLATIONS, INDIVIDUAL PIPING FOR EACH BOILER:

The minimum fl ue stack length is 5 feet and the combined pressure drop of

the air intake and exhaust piping should not exceed 1.0”wc. This is typically the

equivalent of 70 ft and 8 elbows (combining the distances between the intake

and exhaust pipes). If a negative pressure is present in the stack during some

operating conditions, it should never be below -0.05”wc.

!

WARNING

Do not use the boiler as support for

ducted air piping. Ducted piping

must be supported independently of

the boiler.

Cements for plastic pipe are

fl ammable liquids and should

be kept away from all sources of

ignition. Proper ventilation should

be maintained to reduce the hazard

and to minimize breathing of cement

vapors. Avoid contact of cement with

skin and eyes.

4

CAUTION

Insulation should not be used on PVC,

CPVC, or polypropylene materials as it

may elevate pipe wall temperatures,

resulting in the potential for vent

material failure.

Appropriate cement must be used

when joining PVC to CPVC materials.