Installation – Fulton Caliber (CAL) Condensing Hydronic Boiler User Manual

Page 20

© The Fulton Companies 2014

INSTALLATION

CAL-IOM-2014-0129

SECTION 2

2-14

2. Piping must be installed such that no piping stresses

are transmitted to the boiler. The boiler cannot be used

as a pipe anchor.

3. The boiler and all gas piping connections must be

pressure-tested and checked for leaks before being

placed into service. Test with compressed air or inert

gas, if possible.

4. The boiler must be disconnected at the boiler manual

shutoff valve (located at the end of the supplied gas

train) from the gas supply piping system during any

pressure testing of the system at pressures in excess of

1/2 psig (14 inch W.C.).

5. Gas piping must be installed in accordance with

National Fuel Gas Code, ANSI Z223.1 (1991) or latest

addenda, and any other local codes which may apply.

6. The pipe and the fi ttings used must be new and free of

dirt or other deposits.

7. Piping must be of the proper size to ensure adequate

gas supply. A drip leg and union connection must be

installed upstream of the gas safety shut off valves.

8. Connect gas supply line to the open end of the tee on

which the drip leg is installed.

9. When making gas-piping joints, use a sealing

compound resistant to liquefi ed petroleum gases. Do

not use Tefl on tape on gas line threads.

10. After gas piping is completed and before wiring

installation is started, carefully check all piping

connections(factory and fi eld) for gas leaks. Use a soap

and water solution.

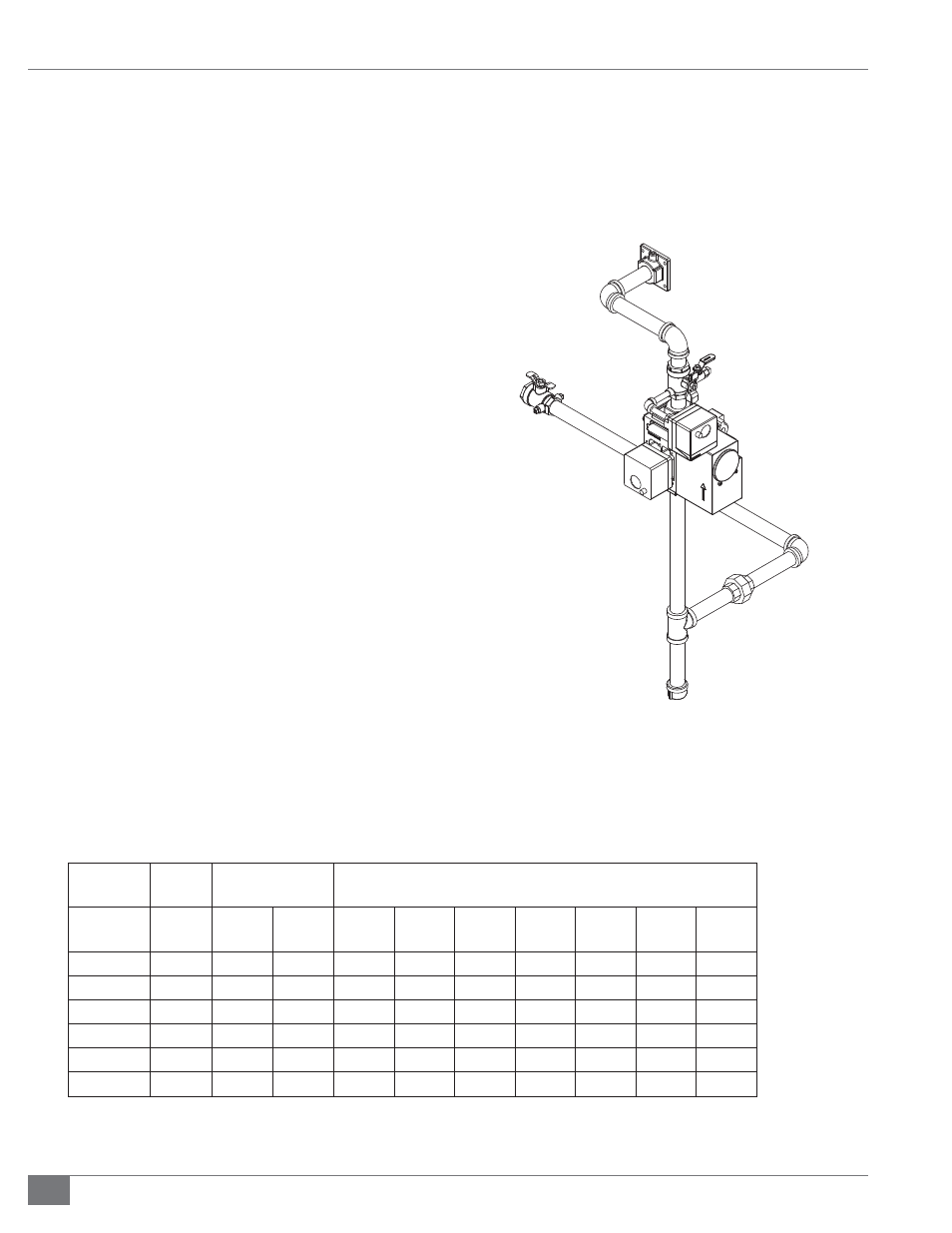

FIGURE 6 - TYPICAL GAS TRAIN

TABLE 4 - NOMINAL PIPE SIZE

Nominal

Pipe Size

ID

Equivalent Pipe

Length

Max Capacity in ft3 of natural gas per hour. Pressure drop of

0.5”wc/Equivalent length of pipe (feet)

(“)

(“)

90 Elb

(Feet)

Tee

(Feet)

20

40

60

80

100

150

200

1-1/4

1.380

3.45

6.9

950

-----

-----

-----

-----

-----

-----

1-1/2

1.610

4.02

8.04

1460

990

810

-----

-----

-----

-----

2

2.067

5.17

10.3

2750

1900

1520

1300

1150

950

800

2-1/2

2.469

6.16

12.3

4350

3000

2400

2050

1850

1500

1280

3

3.068

7.67

15.3

7700

5300

4300

3700

3250

2650

2280

4

4.026

10.1

20.2

15800

10900

8800

7500

6700

5500

4600