Installation, Intake duct sizing – Fulton Caliber (CAL) Condensing Hydronic Boiler User Manual

Page 25

Questions? Please Contact Your Local Manufacturer’s Representative

SECTION 2

CAL-IOM-2014-0129

INSTALLATION

2-19

Intake Duct Sizing

Adhere to the following:

1. Air intake ducting must be sized in conjunction with the

exhaust venting to provide no greater than a 1.0” W.C.

combined pressure drop. This equates to 70 feet and 8

elbows when combining the distances on the air intake

and exhaust with the piping diameters matching the

standard connections.

2. The installation of a recognized termination screen

is required. Contact your local venting supplier for

assistance in venting sizing.

3. Air Intake pipes and fi ttings shall be Schedule 40

PVC pipe or galvanized steel. All Schedule 40 PVC

pipe, fi ttings, primer and cement must conform

with American National Standard Institute and the

American Society for Testing and Materials (ANSI/ASTM

standards.)

4. Intake PVC piping must be assembled using cement.

This will ensure that the intake is airtight and will not

allow contaminates from the boiler room into the

boiler. The cement shall be free fl owing and contain

no lumps, un-dissolved particles or any foreign matter

that adversely aff ects the joint strength or chemical

resistance of the cement. The cement shall not show

gelation, stratifi cation, or separation that cannot be

removed by stirring.

5. Refer to PVC manufacturer’s requirements for proper

installation.

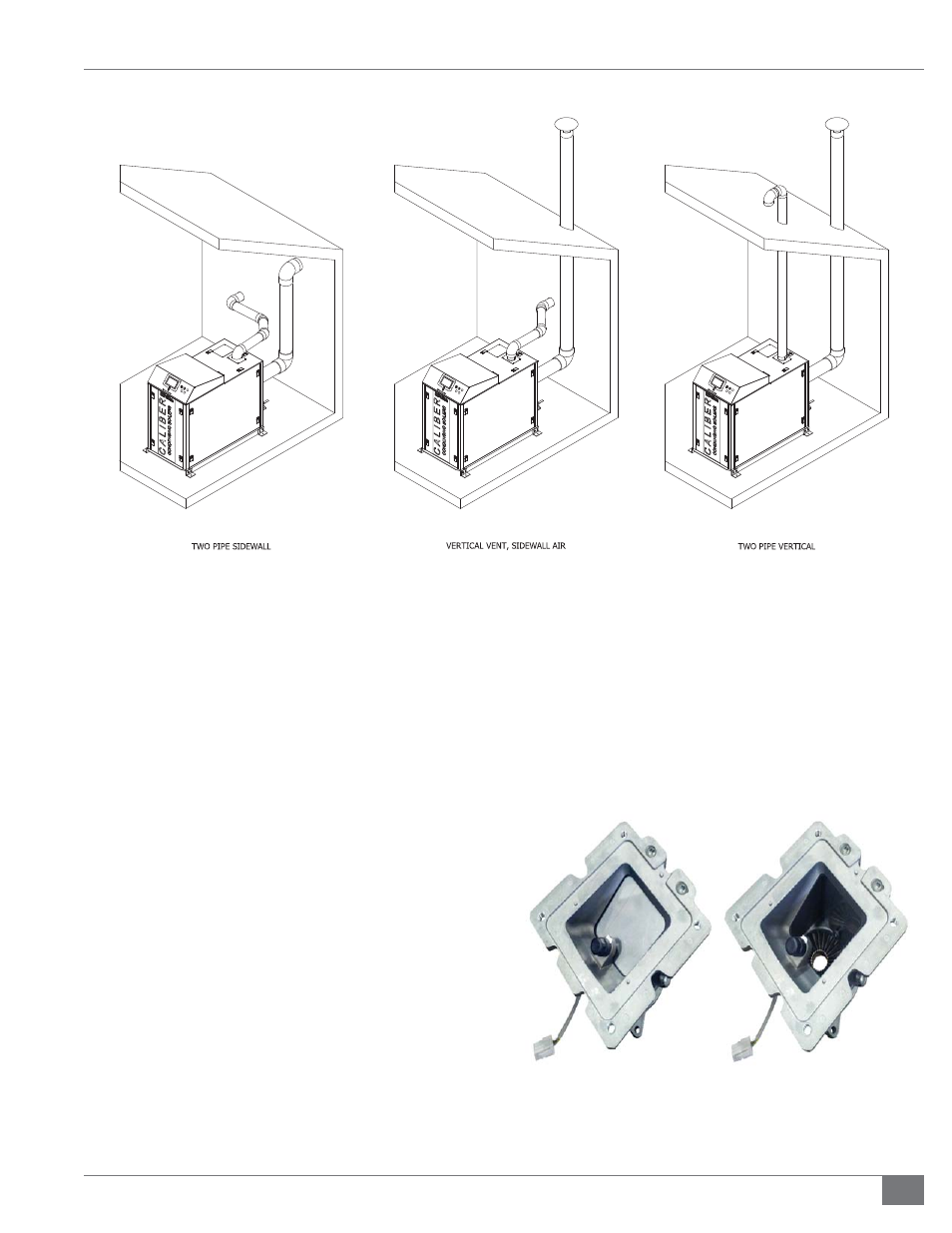

FIGURE 9 - CHECK VALVE FOR COMMON-VENTED BOILERS

FIGURE 8 - VENTING CONFIGURATIONS