PASCO ME-6617 ROCKET ENGINE TEST BRACKET User Manual

Page 4

Rocket Engine Test Bracket

012-06418A

4

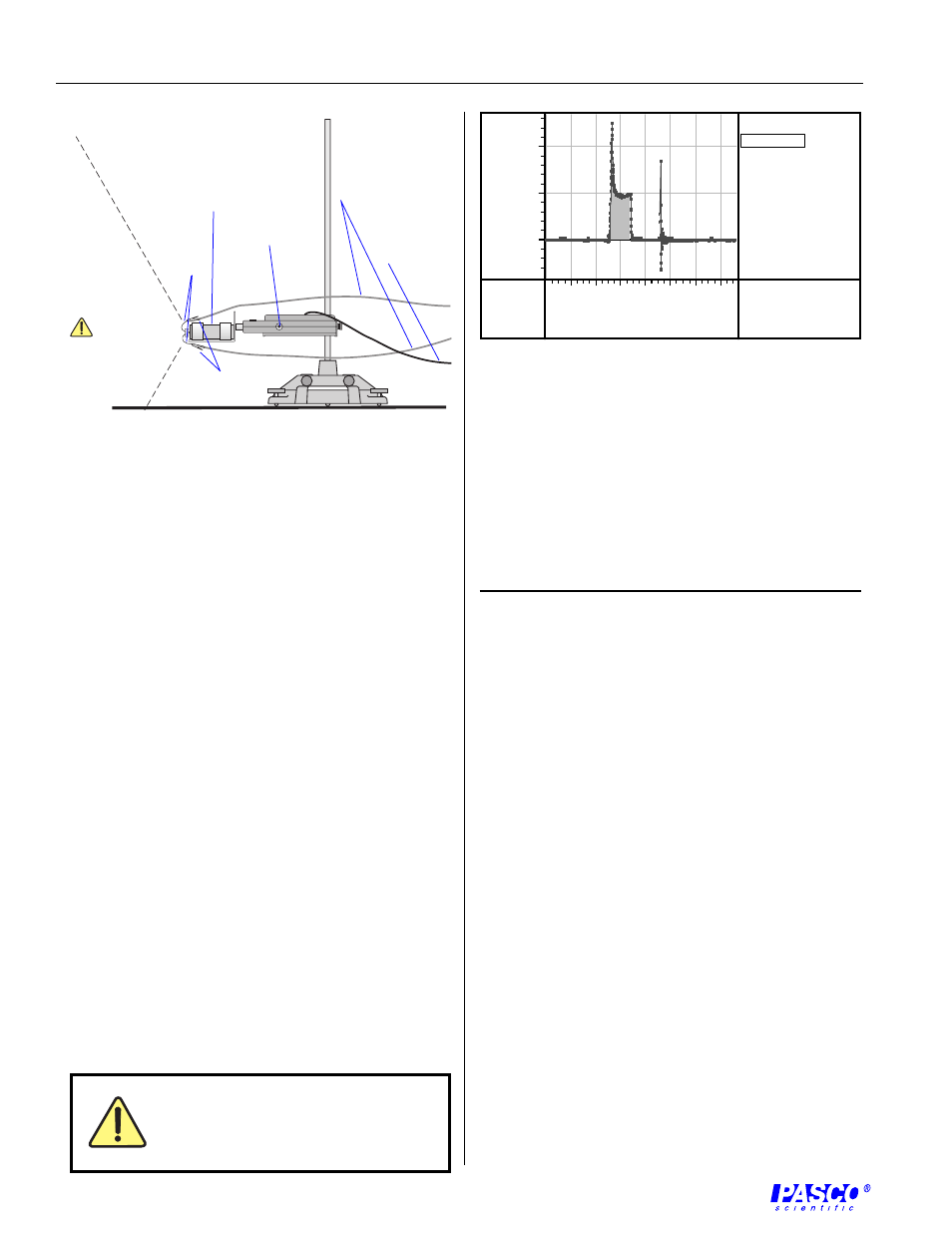

Figure 5

Graph of typical experimental results of a test of an Estes

C6-3 model rocket engine

Limited Warranty

PASCO scientific warrants the product to be free from

defects in materials and workmanship for a period of one

year from the date of shipment to the customer. PASCO

will repair or replace, at its option, any part of the product

which is deemed to be defective in material or

workmanship. The warranty does not cover damage to

the product caused by abuse or improper use.

Determination of whether a product failure is the result of

a manufacturing defect or improper use by the customer

shall be made solely by PASCO scientific. Responsibility

for the return of equipment for warranty repair belongs to

the customer. Equipment must be properly packed to

prevent damage and shipped postage or freight prepaid.

(Damage caused by improper packing of the equipment

for return shipment will not be covered by the warranty.)

Shipping costs for returning the equipment after repair will

be paid by PASCO scientific.

Address:

PASCO scientific

10101 Foothills Blvd.

P.O. Box 619011

Roseville, CA 95678-9011

Phone:

(916) 786-3800

FAX:

(916) 786-8905

email:

web:

www.pasco.com

Calculate the expected height of a rocket propelled with

an identical rocket engine from the force and mass data,

and compare with the actual height attained in a flight test.

Suggested Activity

5.

Press the TARE button on the Force Sensor (Figure 4).

➤

Note:

For the 500 interface in remote mode,

press the TARE button after the log button has

been pressed and the LED has flashed 10 times.

6.

Check the exhaust area to ensure it is clear of any

combustible material, people, or animals.

Data Collection

1.

Insert the safety key into the launch controller.

2.

Begin recording data and move to 15 feet (5 meters)

away from the Rocket Engine Test Bracket.

3.

Ignite the rocket.

4.

After the burn, stop recording data.

Data Analysis

1.

In Science Workshop, click the statistics button and

select Integration from the pop-up menu, and click

the Autoscale button to resize the graph.

2.

Select the area under the curve and record the

integrated value (impulse of the rocket engine).

3.

Use the smart cursor to determine the time to the

ejection charge.

4.

Compare your recorded values with the expected

values for the type of you are using.

The exclamation point within an

equilateral triangle is intended to alert the

user of important operating and safety

instructions that will help prevent damage

to the equipment or injury to the user.

T

A R E

Keep

exhaust

area clear!

to electronic

launch controller

Figure 4

Completed experimental setup

to computer

interface

igniter

wires

cable clips

model

rocket

engine

Force

Sensor’s

TARE

button

Time (s)

0

2

4

6

8

10

12

14

Integration

area = 8.51336 N s

0

5

10

R

un #1

F

o

rce

(N

)