A.O. Smith VB/VW-500 User Manual

Page 9

9

WATER TEMPERATURE LIMIT CONTROLS

The “V(B/W)” models incorporate an outlet water probe consisting

of two limit controls:

1. An adjustable automatic high limit control that can be set as

high as either 210°F (99°C) or 235°F (113°C), depending on

the application.

2. A fixed manual high limit (ECO), factory set at 244°F (118°C). If

the manual reset should open due to high temperature, the

gas valves will close and the unit will go into lockout. If lockout

occurs, push the SELECTION button on the UIM to restart the boiler.

ON/OFF SWITCH

The ON/OFF Switch is a single-pole, single-throw rocker switch.

This switch provides 120V from the line source to the boiler.

CIRCULATING PUMP

HOT WATER SUPPLY BOILER-VW, the circulating pump is

integral to the VW models. This pump has been lubricated at

the factory, and future lubrication should be in accordance

with the motor manufacturer’s instructions provided as a

supplement to this manual.

FOR HOT WATER HEATING BOILERS-VB MODELS, the

circulating pump is NOT provided on standard models (optional)

and must be obtained and installed in the field.

NOTE: If a system pump is to be installed on a VB

model, the maximum rating of the pump motor must

not exceed 1 hp.

REMOTE PROBE

FOR HOT WATER SUPPLY BOILERS-VW models, a remote

probe is supplied with each hot water supply boiler. The inlet water

temperature and the tank temperature are displayed separately

on the default menu screen.

Note: The remote probe must be designated as the controlling probe

using dipswitch “4” on MCB before it can be used for VW hot water

supply applications, see page 29 (MCB -Ten Position Dip Switch).

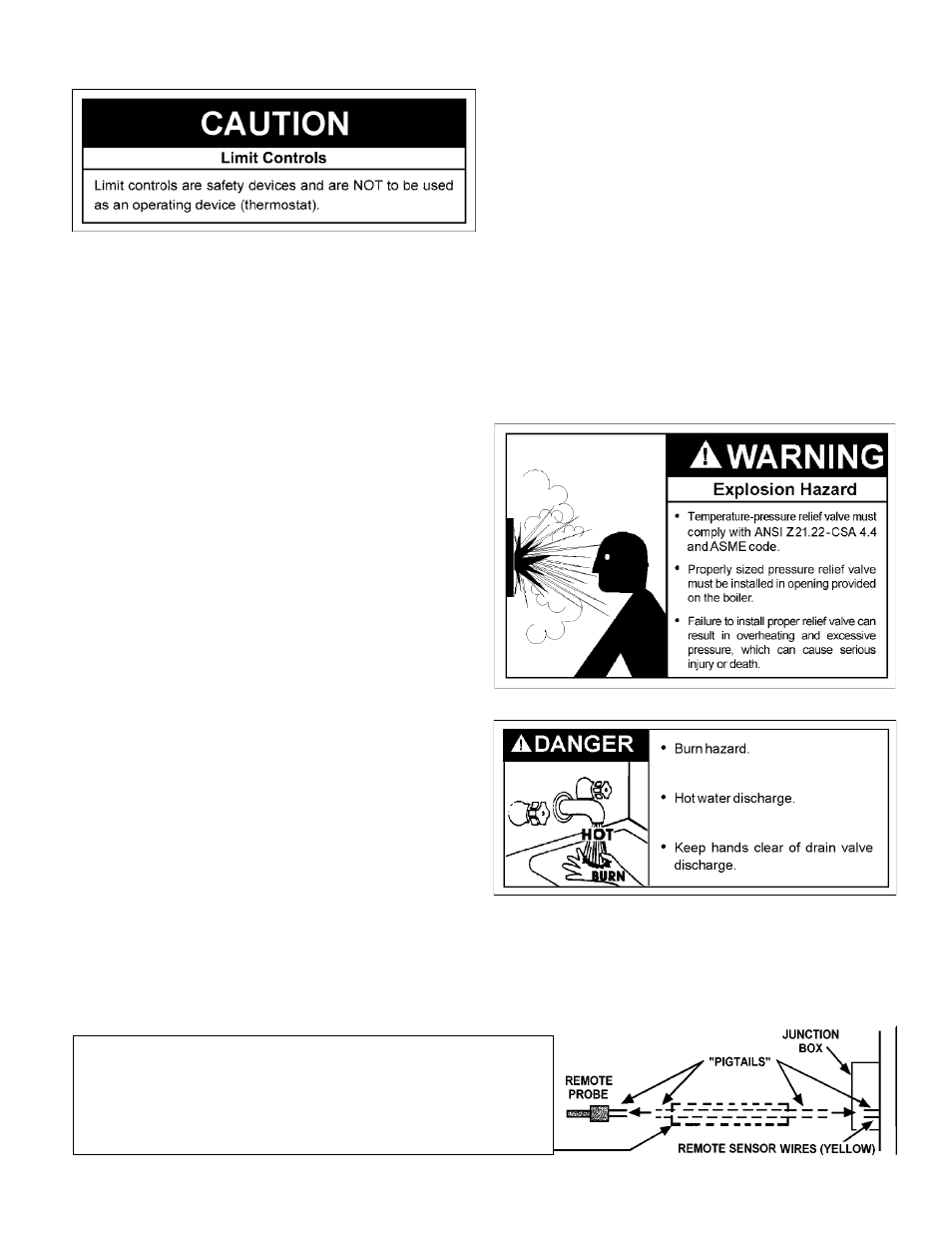

“Pigtails” of field-supplied yellow wires located in the rear of

the unit in the junction box should be spliced to “pigtails” of

remote probe and connected in the junction box. See Figure 7

for probe installation.

FOR HOT WATER HEATING BOILERS-VB models, a remote

probe is supplied due to the various types of systems and operating

conditions. A remote probe can be used as an option to control

loop temperature and unit staging. Additionally, the inlet

temperature probe can be used as the loop thermostat in some

heating applications. The remote probe connects to designated

wires in the junction box at the rear of the boiler, refer to the PROBE

INSTALLATION section. Do not operate this boiler using the

internal high limits only; use a remote probe or operating

thermostat to control system temperatures.

LOW WATER CUTOFF (Optional)

If low water detection is required by the authorities having

jurisdiction, a low water cutoff switch should be installed next to

the boiler in the outlet water line as shown in Figure 13. The switch

should receive periodic (every six months) inspection to assure

proper operation. A Low Water Cutoff device of the float type should

be flushed every six months.

SAFETY RELIEF VALVE

The purpose of a safety relief valve is to avoid excessive pressure

or temperature into the steam range which may cause scalding at

fixtures, tank explosion, system damage, or boiler damage.

To avoid scalding or water damage, a drain line must be

connected to a safety relief valve to direct discharge to a safe

FIGURE 7. REMOTE PROBE INSTALLATION.

Encase field-supplied wires between remote probe and junction box with

1/2" field supplied conduit. "Pigtails" of field-supplied wires should be

spliced to "pigtails" of remote probe. This conduit and wiring should be

separate from any other conduit/wiring to guard against EMI

(electromagnetic interference).