Operation – A.O. Smith VB/VW-500 User Manual

Page 27

27

OPERATION

IMPORTANT

Only qualified personnel shall perform the initial firing of the boiler.

At this time the user should not hesitate to ask the start-up

technician any questions regarding the operation and maintenance

of the unit. If you still have questions, please contact the factory

or your local A.O. Smith representative.

Lighting and Operating instructions are included with this manual.

By using these instructions, the user may be able to make minor

operational adjustments and save unnecessary service calls.

However the user should not attempt repairs, but should contact a

service technician or gas supplier.

GENERAL

Never operate the boiler without first making sure the boiler and

system are filled with water, in addition:

For hot water supply installations:

• Make sure a temperature and pressure relief valve is installed

at the boiler and, if used, the storage tank. Also check for leaks.

For heating boiler installations:

• Make sure that the boiler and system have been purged of air

and checked for leaks.

Also be sure to check the gas piping for leaks before beginning

the initial firing of the boiler.

FILLING AND PURGING OF HEATING

BOILER INSTALLATION

1. Fast fill system through bypass until pressure approaches

desired system pressure. Close bypass valve and permit

pressure to be established by the pressure reducing valve.

2. Vent all high points in system to purge system of air.

Provisions should be made to permit manual venting of radiators

or convectors.

FILLING HOT WATER SUPPLY

BOILER INSTALLATION

1. Close the system’s drain valve by turning handle clockwise.

2. Open a nearby hot water faucet to permit the air to escape.

3. Fully open the cold water inlet pipe valve allowing the boiler

and piping to be filled.

4. Close the hot water faucet as water starts to flow.

5. The boiler is ready to be operated.

PURGING GAS LINE

Gas line purging is required with new piping or systems in which

air has entered.

INLET GAS PRESSURE

The inlet gas pressure is measured by removing the 1/8” NPT Plug

located on the main gas manifold which is upstream of the unit’s gas

valve, and insert a 1/8” NPT hose barb fitting to be connected to a

manometer or pressure gauge. Once pressure has been checked

and/or adjusted, replace the plug and check for leaks. The maximum

value specified in the table must not be exceeded. The minimum

values, shown in Table 1, must be maintained under both load and no

load conditions (static and firing conditions). The combination gas

valves supplied with the boiler are for low pressure service. If

upstream pressure exceeds 11.0” W.C., an intermediate gas

pressure regulator of the lockup type must be installed.

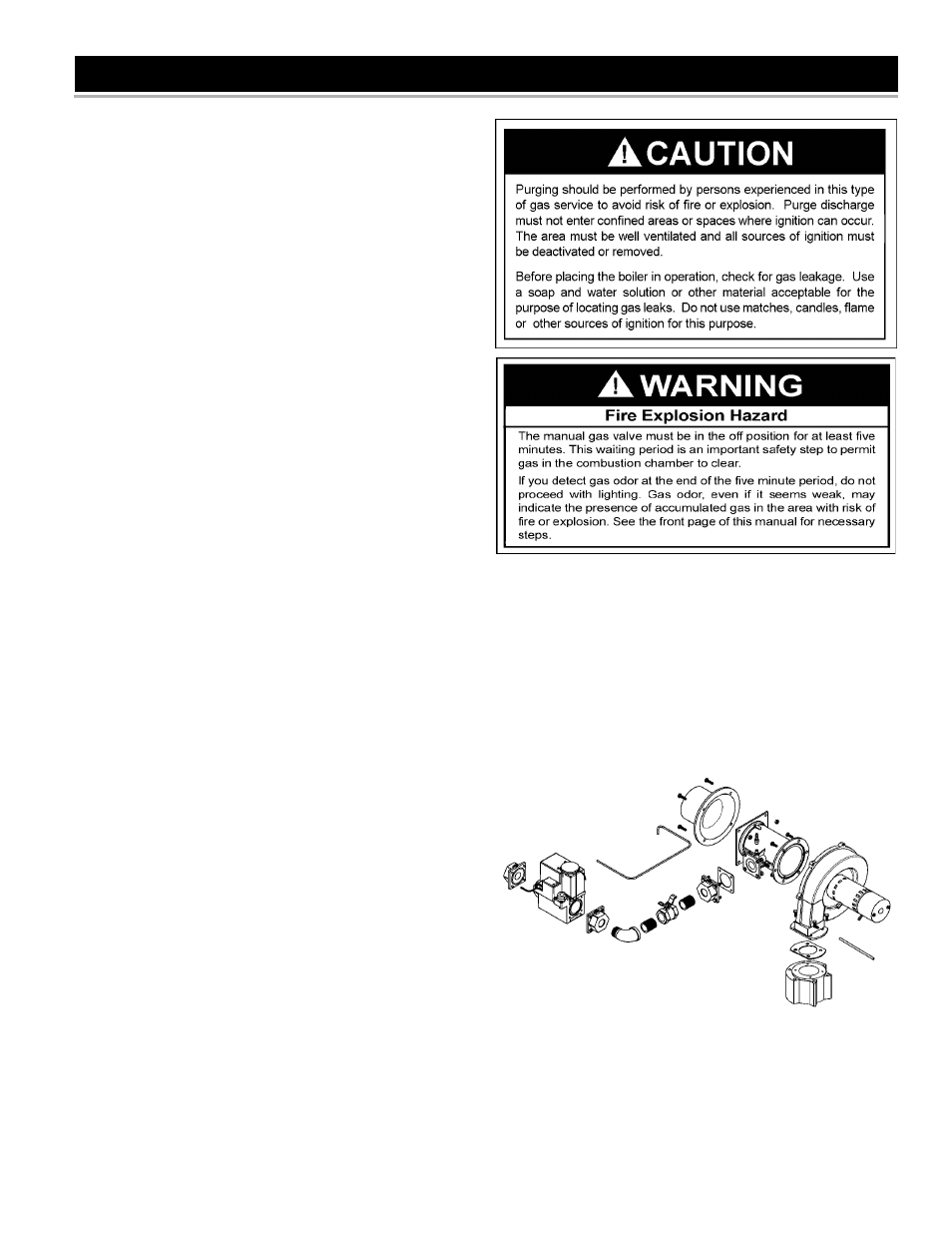

FIGURE 16. GAS TRAIN ASSEMBLY.