A.O. Smith VB/VW-500 User Manual

Page 11

11

shall be wide enough to allow the boiler to enter or to permit the

replacement of another appliance such as a boiler.

LEVELING

Each unit should be checked after installation to be certain

that it is level.

If the unit is not level, obtain and insert shims under the feet at the

frame base to correct this condition.

AIR REQUIREMENTS

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion, ventilation,

and draft hood dilution must be obtained from outdoors or spaces freely

FIGURE 8.

CHEMICAL VAPOR CORROSION

Boiler corrosion and component failure can be caused by the

heating and breakdown of airborne chemical vapors. Spray can

propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride (water softener salt), waxes, and process chemicals are

typical compounds which are potentially corrosive. These materials

are corrosive at very low concentration levels with little or no odor

to reveal their presence.

Products of this sort should not be stored near the boiler. Also, air

which is brought in contact with the boiler should not contain any

of these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. Failure to observe this

requirement will void the warranty.

INSTALLATION CLEARANCES

This boiler MUST NOT be installed on carpeted floors. This boiler is

approved for installation on combustible flooring in an alcove with

minimum clearances to combustibles of:

4" (102mm) Rear; 0" (0mm) Top and Sides; 6" (152mm) Vent. 2” (51mm)

clearance is allowable from combustible construction for hot water pipes.

Sufficient area should be provided at the front and rear of the unit for

proper servicing. Service clearances of 24" (610mm) in front, rear, top

and sides are recommended. In a utility room installation, the door opening

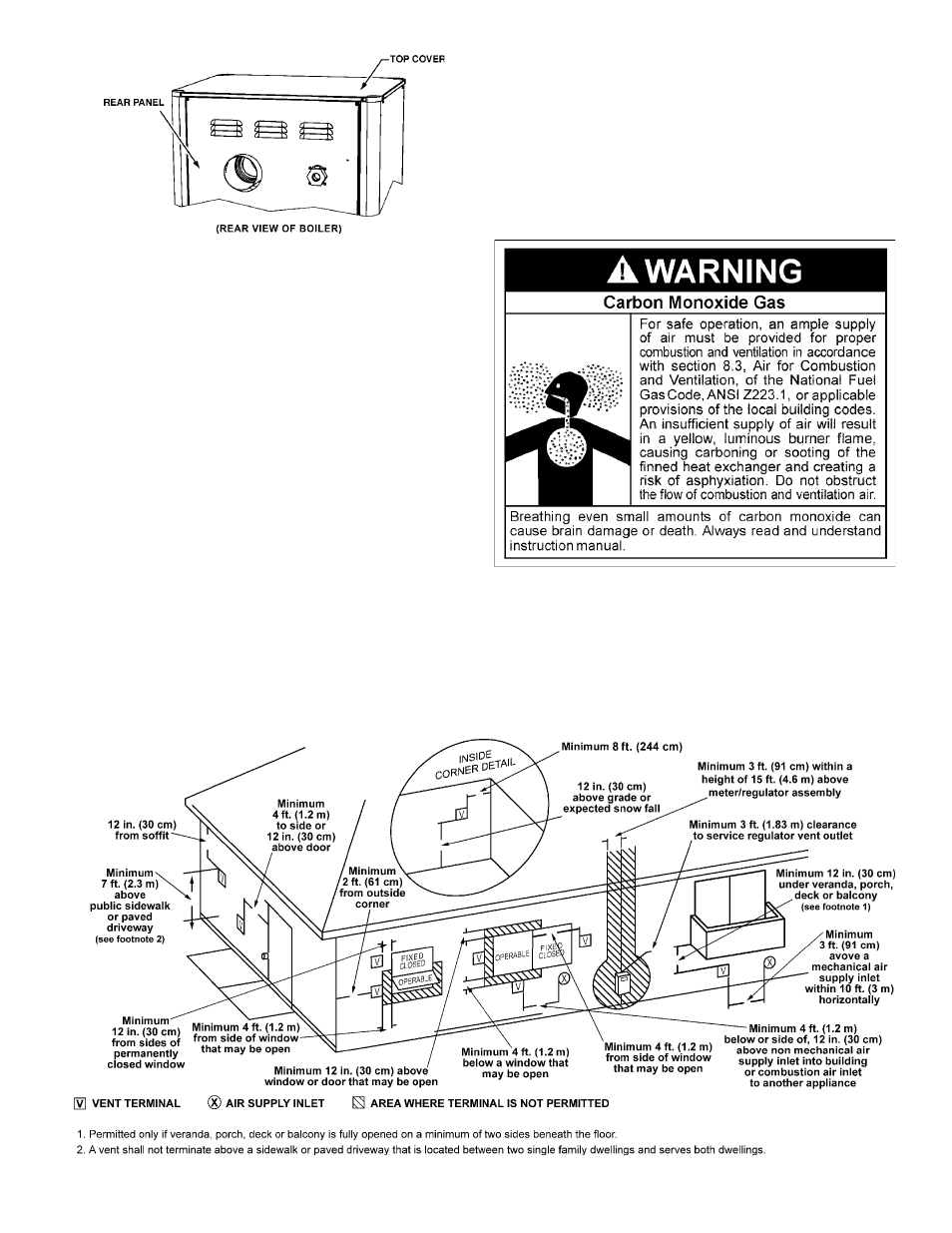

FIGURE 9. SIDEWALL EXHAUST VENTING