Gas connections – A.O. Smith VB/VW-500 User Manual

Page 20

20

This is accomplished by changing two dipswitch settings on

the MCB. First, dipswitch “4” must be set to the “ON” position

to designate the remote probe as the controlling probe.

Second, dipswitch “1” must be set to the “OFF” position to

limit the maximum remote probe temperature for VW

applications. Also, make sure dipswitch “1” is set to the

“OFF” position, which sets the outlet temperature for VW

applications. Failure to do this will void the warranty. If the

remote probe is not designated as the controlling probe, the

unit will be controlled by the inlet probe and will not use the

desired tank temperature as its base.

Refer to Connection Diagram, Figure 18, in order to connect

the remote probe to the boiler, see page 29 for Dipswitch

positions.

GAS CONNECTIONS

Make sure the gas on which the boiler is to operate is the

same as that specified on the rating plate. Do not install

the boiler if equipped for a different type of gas. Consult

your gas supplier.

This boiler is not intended to operate at gas supply

pressure other than shown on the rating plate. A lock-up

or positive shut-off type regulator must be installed in the

gas supply line. Exposure to higher gas supply pressure

may cause damage to gas valves which can result in fire

or explosion. If overpressure has occurred such as through

improper testing of gas lines or emergency malfunction of

the supply system, the gas valves must be checked for

safe operation. Make sure that the outside vents on the

supply regulators and the safety vent valves are protected

against blockage. These are parts of the gas supply system,

not the boiler. Vent blockage may occur during ice build-up

or snowstorms.

The boiler must be isolated from the gas supply piping

system by closing its main manual gas shut-off valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig.

Disconnect the boiler and its main manual gas shut-off valve

from the gas supply piping during any pressure testing of the

gas supply system over 1/2 psig. The gas supply line must be

capped when not connected to the boiler.

It is important to guard against gas valve fouling from

contaminants in the gas ways. Such fouling may cause

improper operation, fire or explosion. If copper supply

lines are used they must be approved for gas service.

When local codes require a main manual shut-off valve

outside the boiler jacket, a suitable main manual shut-

off valve must be installed in a location complying

with those codes.

Before attaching the gas line be sure that all gas pipe is clean on

the inside.

To trap any dirt or foreign material in the gas supply line,

a dirt leg (sometimes called drip leg) must be incorporated

in the piping. The dirt leg must be readily accessible and

not subject to freezing conditions. Install in accordance

with recommendations of serving gas supplier. Refer to

national fuel gas code, ANSI Z223.1 or CAN/CSA – B149.1,

and current addenda.

Size of gas supply piping may be larger than heater connection on

installations where a significant run of piping is required.

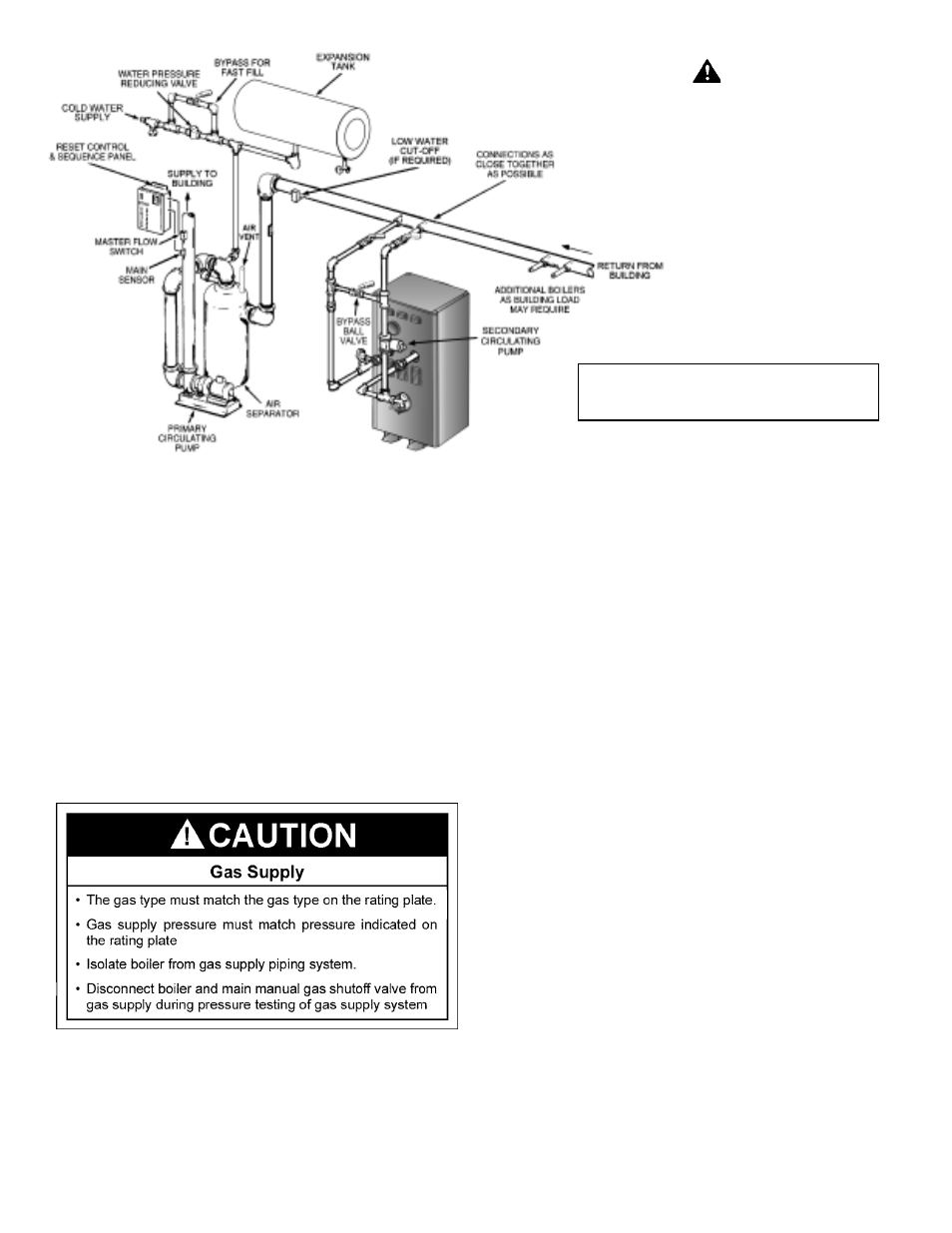

FIGURE 13. TYPICAL PRIMARY, SECONDARY PIPING.

• INSTALL IN ACCORDANCE WITH ALL LOCAL CODES.

• WHEN BLOW DOWN VALVE IS REQUIRED, INSTALL

IN PLACE OF THE DRAIN VALVE SHOWN.

DANGER

TEMPERATURE SETTING SHOULD NOT

EXCEED SAFE USE TEMPERATURE AT

FIXTURES. IF HIGHER PREHEAT

TEMPERATURES ARE NECESSARY TO OBTAIN

ADEQUATE BOOSTER OUTPUT, ADD AN ANTI-

SCALD VALVE FOR HOT WATER SUPPLIED TO

FIXTURES, SEE TABLE 11.