Features – A.O. Smith VB/VW-500 User Manual

Page 8

8

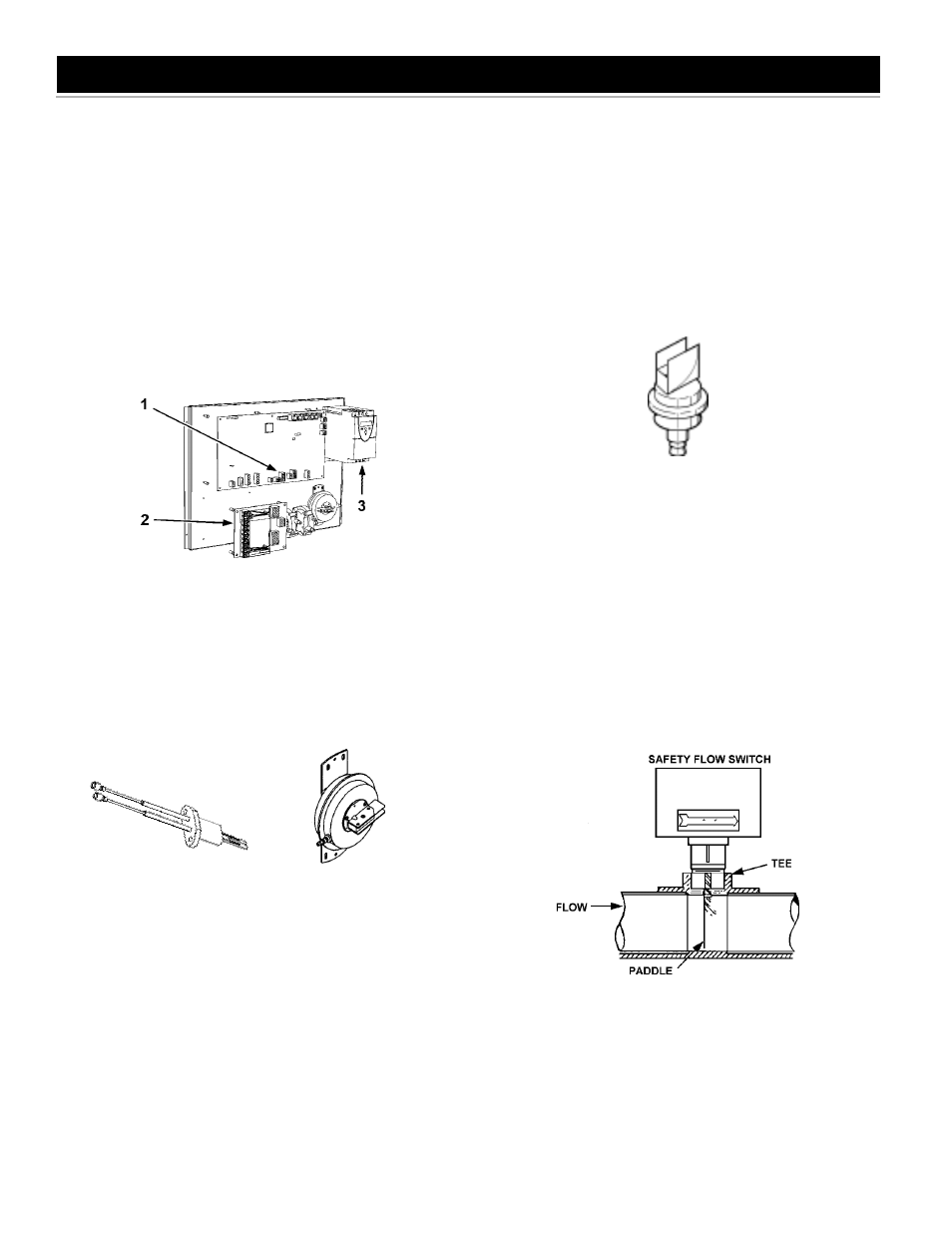

THE CONTROL SYSTEM

The control system consists of four basic components:

1) Modulation Control Board (MCB); 2) Power Distribution Board

(PDB); 3) Variable Frequency Drive (VFD), see Figure 2; 4)

User Interface Module, see Figure 19. The Modulation Control

Board and the Power Distribution Board are located in the control

box and can be accessed by opening the front door of the

unit. The User Interface Module is attached to the front door

panel. Every system will have one Modulation Control Board

(MCB), one Power Distribution Board (PDB), and one User Interface

Module (UIM).

The MCB contains dipswitches which are used to configure

the boiler for several different control options,

see the Control

System Section.

FIGURE 2.

HOT SURFACE IGNITER

The Hot Surface Igniter is a device that ignites the main burner by high

temperature (>1800°F) [982°C], see Figure 3. The igniter is made of

recrystallized silicon carbide, and when 120 VAC is applied to the igniter,

sufficient heat is generated to ignite the main burner. Although

improvements have been made to strengthen the igniter, it is still fragile

and care must be taken in handling the igniter to prevent breakage.

FIGURE 3.

FIGURE 4.

BLOCKED EXHAUST SWITCH

The Blocked Exhaust Switch, see Figure 4, ensures that the vent

system is clear. This exhaust switch is normally closed and only

opens on fault conditions.

BLOWER PROVER SWITCH

This VF boiler has two blower prover switches (BPS). The low

blower prover switch is a single-pole, normally open pressure switch

that closes on increased negative pressure. The low BPS closes

when the blower starts and remains closed during the operation of

the heating cycle.

The second BPS is the high BPS. It is also a single-pole, normally

open pressure switch that closes on increased negative pressure.

The high BPS closes only when the blower is in pre and post purge.

If the high BPS closes at any time during the heating cycle, the

boiler will shut off.

OPTIONAL LOW/HIGH GAS SWITCH

This VF boiler is available with optional low and high gas pressure

switches which meet the CSD-1 code requirements, see Figure 5.

The low gas switch is normally closed and remains closed unless

pressure falls below the preset pressure. The high gas switch is

normally closed and remains closed unless pressure exceeds the

preset pressure.

FIGURE 5. LOW/HIGH GAS PRESSURE SWITCH.

WATER FLOW SWITCH

The water flow switch is installed at the boiler outlet to

prevent burner operation in the event of inadequate water

flow through the boiler. It is a normally open switch that will

close its contacts when increasing water flow rate is detected.

The water flow switch is factory-set. The contacts will open

when the flow rate drops below the factory setting causing

the gas valve to close which will turn off the gas to the

burner, see Figure 6. Under no circumstances shall the

flow switch be tampered with or bypassed. Doing so may

cause damage to the heat exchanger not covered under

the warranty.

FIGURE 6. WATER FLOW SWITCH.

FLAME SENSOR

Each Boiler is equipped with two flame senors coupled together

to detect the presence of the burner flames at high and low

fire conditions. These flame rods work together as one to

sense the flame.

If no flame is sensed, the gas valve(s) will close

automatically. If no flame is sensed on three ignition trials, the boiler

will lock out. In the event of a lockout, depress the SELECT button

on the display board to restart the boiler.

FEATURES