Manual release adjustment, Magnet coil adjustment – Dings Dynamics Group 90 Series End Mount - 450 lb-ft NEMA 4 User Manual

Page 5

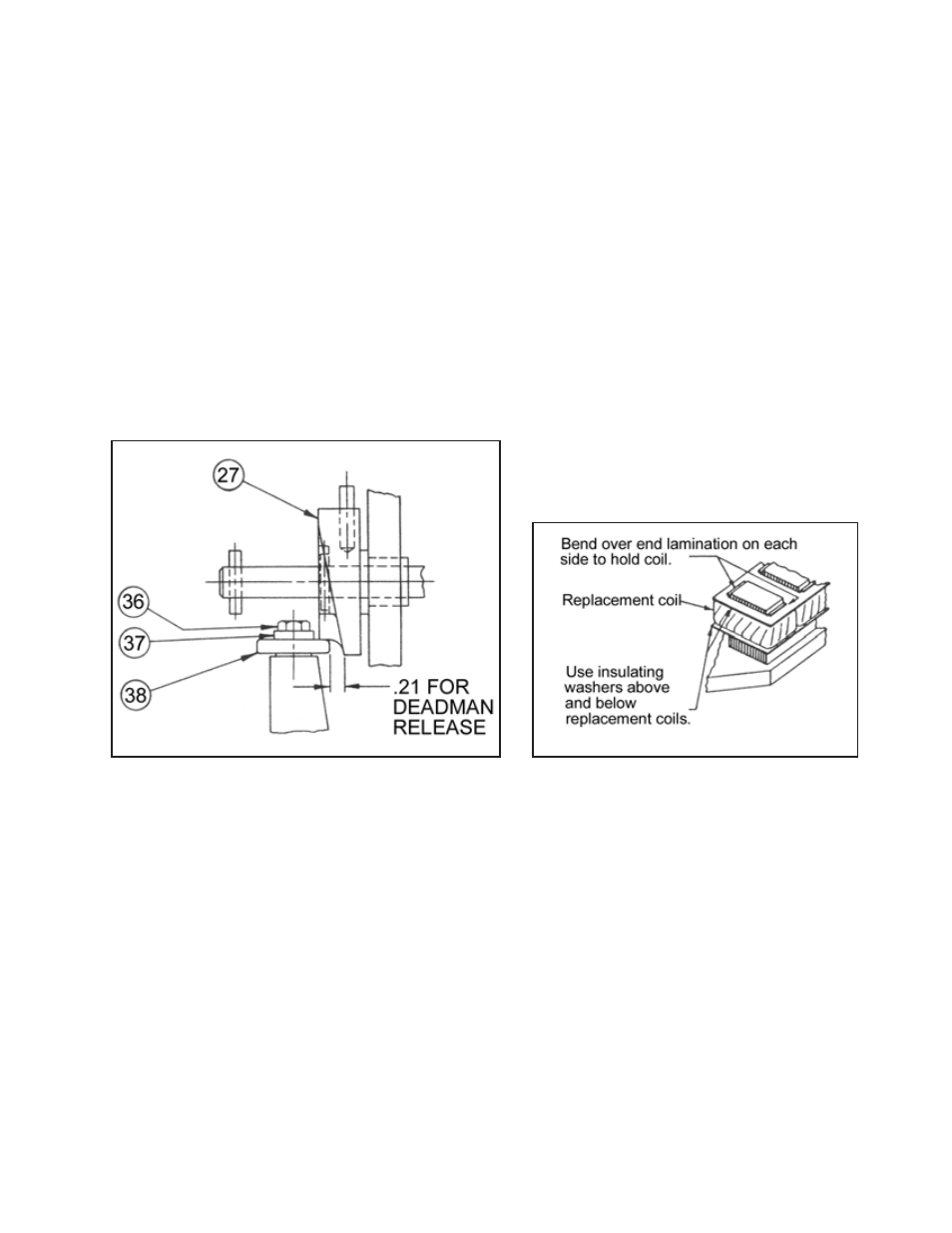

MANUAL RELEASE ADJUSTMENT

(Refer to Figures 3, 7 & 9.)

AUTOMATIC RETURN: Check the manual release. Turn cam (27)

clockwise until it stops. The brake should now be released. The cam

and manual release shaft should return to its normal position when

the brake is energized. If not, adjust as follows: Loosen the cap-

screw (36). With the brake energized and the cam turned clockwise

the stop, turn eccentric bushing (37) until the bearing (38) makes

contact with the cam surface. Hold bushing in this position and tight-

en capscrew. Check manual release for proper operation. NOTE:

Due to the size of the discs, a slight drag is common (5-7 lb. ft.).

DEADMAN: Check the manual release. Turn cam (27) clockwise

until it stops and hold it in this position. The brake should be

released. The cam should return to its normal position when you let

go of cam. If not, adjust as follows: Loosen the capscrew (36). WIth

the brake de-energized and the release cam in its normal position,

turn eccentric bushing (37) until the distance between the bearing

(38) and face on cam (27) measures .21 inches. See Figure 7. Hold

bushing in this position and tighten capscrew. Check manual release

for proper operation. NOTE: Due to the size of the discs, a slight

drag is common (5-7 lb. ft.).

MAGNET COIL ADJUSTMENT

(Refer to Figures 2, 3, 8 & 9.)

NOTE: Do not remove operator assembly from brake, unless

motor load is blocked. Removal of operator or blocking of

operator arm, results in loss of all braking torque.

Remove operator assembly as outlined under FRICTION DISC

REPLACEMENT.

1.

Coils (18) are held in place by epoxy cement or by bent over

end magnet laminations. Force coil off magnet if held by epoxy

and remove excess epoxy from the magnet surfaces, or bend

up the end laminations and remove coil.

2.

Replacement coils are held in place by bending of end lamin-

ations. (See Figure 8.) Insulating washers (19) are used above

and below the coil on replacements. Order insulating washers

when ordering a coil. When installing coils, it is very important

to follow EXACTLY the sequence of the black and white leads

as show n in the wiring diagram. Brake will not operate properly

unless coils are in the correct position. (See Figure 2.)

3.

Reassemble brake as outlined under INSTALLATION.

Figure 8. Fastening of Replacement Magnet Coils

Figure 7.